Floating type feeding device for roller press

A feeding device, floating technology, applied in the field of roller press floating feeding device, to achieve the effect of increasing the bite effect and increasing the friction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

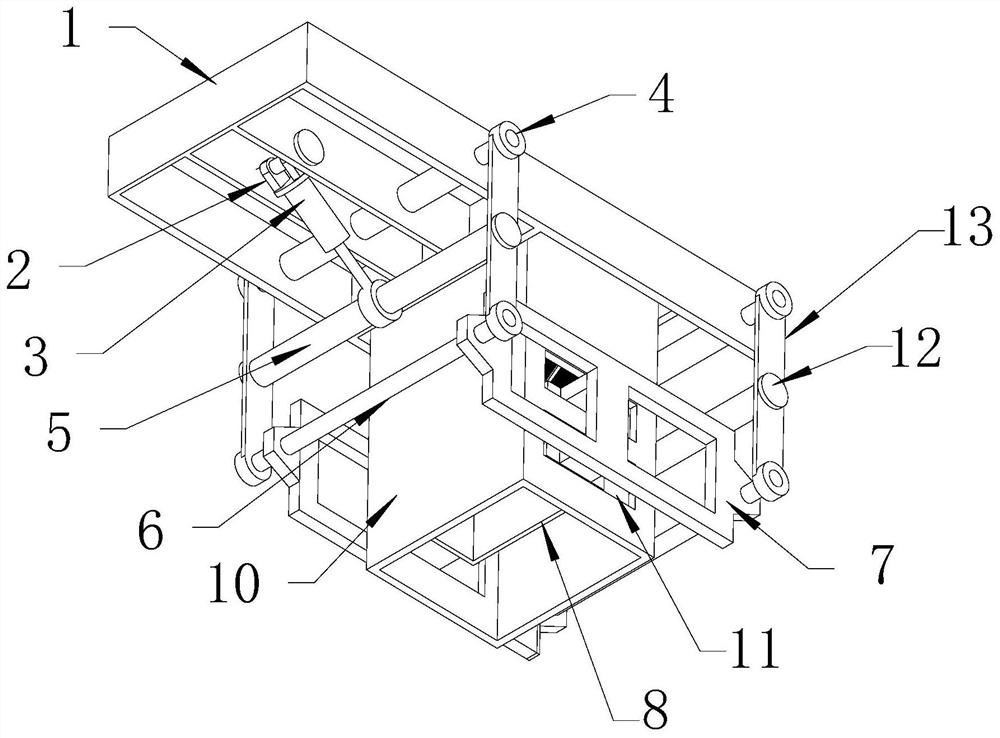

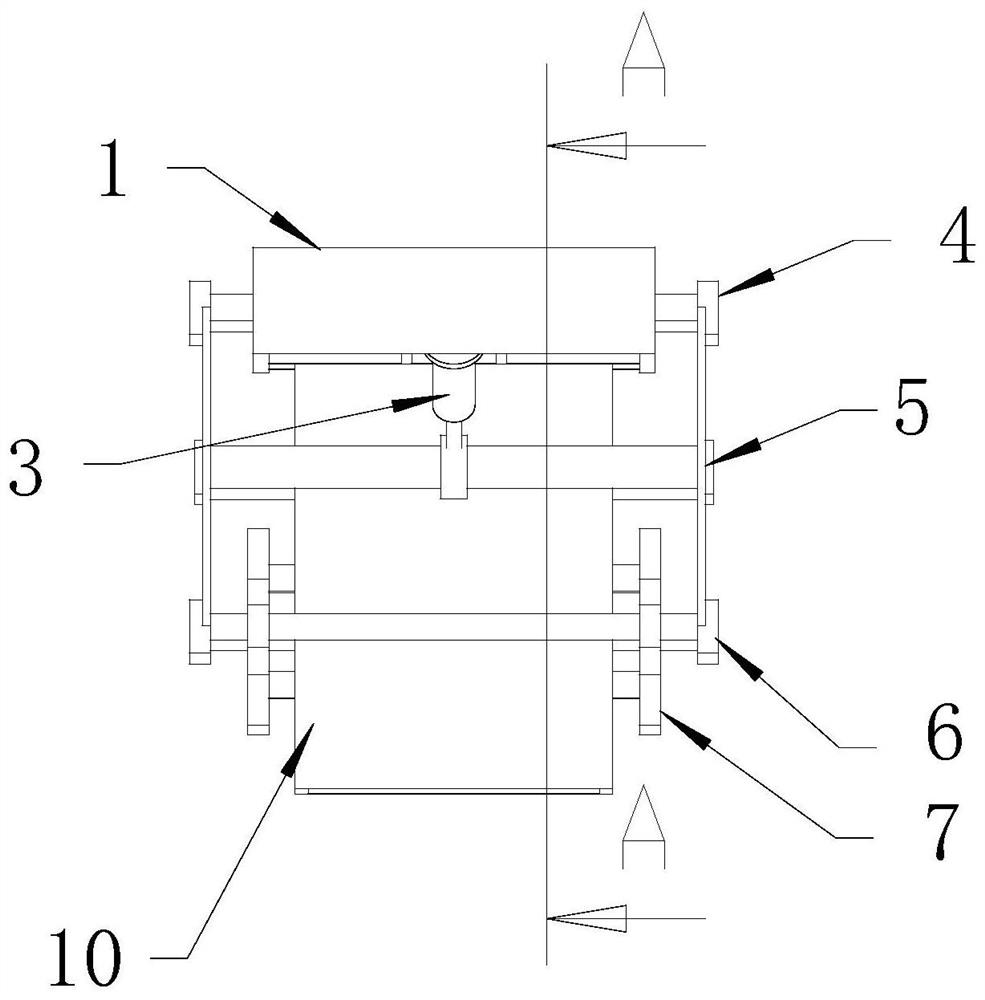

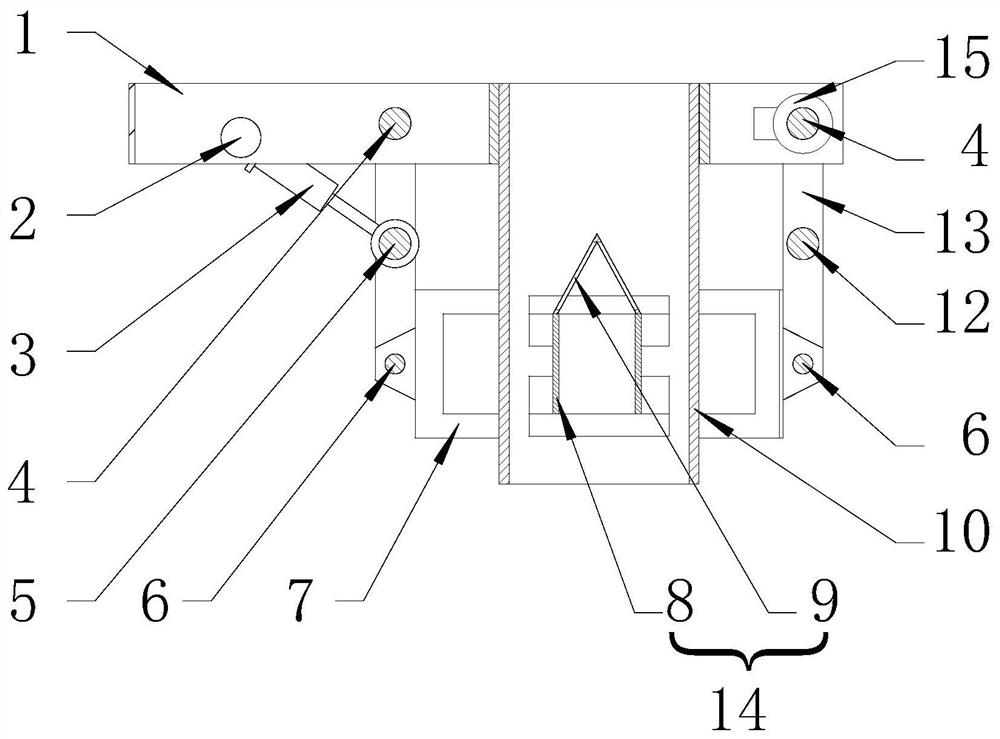

[0027] like Figure 1 to Figure 4 As shown, a floating feeding device for a roller press of the present invention includes a main frame 1 and a feeding channel 10 vertically arranged on the main frame 1. The section of the feeding channel 10 is a square or a rectangle, and the main frame On the frame 1, the two sides of the feeding channel 10 are respectively provided with first suspension pins 4, and the two ends of each suspension pin 4 are respectively connected with swing arms 13; the front and rear sides of the lower part of the feeding channel 10 are The wall is respectively provided with through holes 11, and the outside of each through hole 11 is provided with a swing frame 7, and the inside of the feeding channel 10 is also provided with a screening device 14, and the front and rear sides of the screening device 14 are respectively connected to two swinging frames. The frames 7 are connected and fixed; the two ends of one swing frame 7 are connected with the two ends ...

Embodiment 2

[0030] On the basis of embodiment 1, in order to facilitate the automatic control of the floating feeding device of the roller press, as Figure 1 to Figure 5As shown, the feeding device also includes a PLC controller 16 and a hydraulic station 17, wherein an angle sensor 15 is installed at the end of one of the first suspension pins 4, and the ejector device 3 and the hydraulic station 17 The hydraulic station 17 and the angle sensor 15 are respectively connected to the PLC controller 16 through lines. In this embodiment, the PLC controller 16 can be connected with the roller press control system, and according to the data of the roller press operation and the feedback data of the angle actuator 15, the PLC program instruction is transmitted to the hydraulic station 17, and the hydraulic station 17 is controlled to Hydraulic oil is pumped into the ejector device 3 to drive the extension and contraction of the ejector device 3, and then control the position of the screening de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com