Flexible fixing mechanism for workpiece lifting appliance

A technology of fixing mechanism and spreader, which is applied in the direction of load hanging components, transportation and packaging, etc. It can solve the problems of heavy operation workload, inability to meet the needs of automatic production, and low degree of flexibility, so as to ensure reliability and safety , to meet the convenience, to meet the effect of precise docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0026] The flexible fixing mechanism of the workpiece hanger provided by the present invention is used for the automatic assembly of workpieces. The floating mechanism provides the redundancy for the insertion of the workpiece hanger, so that the workpiece hanger meeting a certain tolerance condition can be accurately docked with the automation equipment; The fixing mechanism automatically detects the insertion state of the workpiece hanger and locks it automatically, which not only meets the convenience of manual operation, but also meets the precise docking with the automation equipment, and also ensures the reliability and safety of the workpiece assembly process.

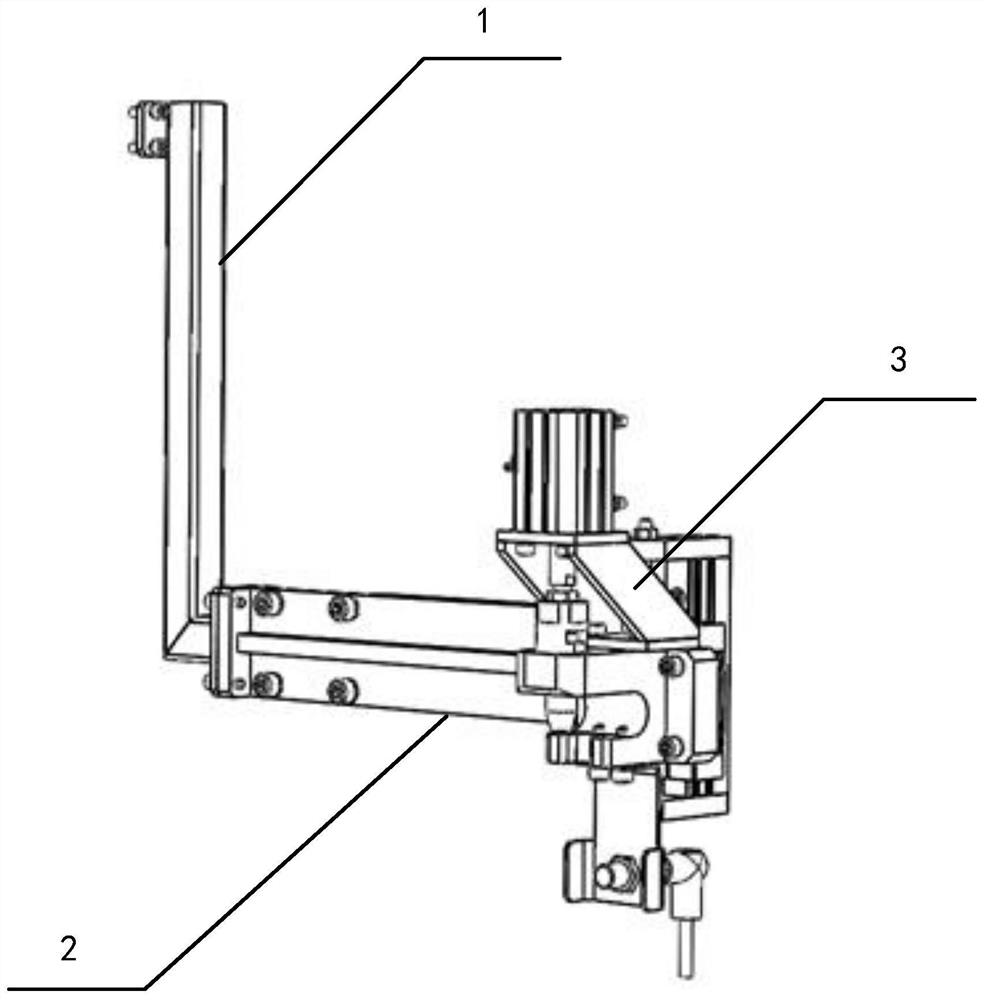

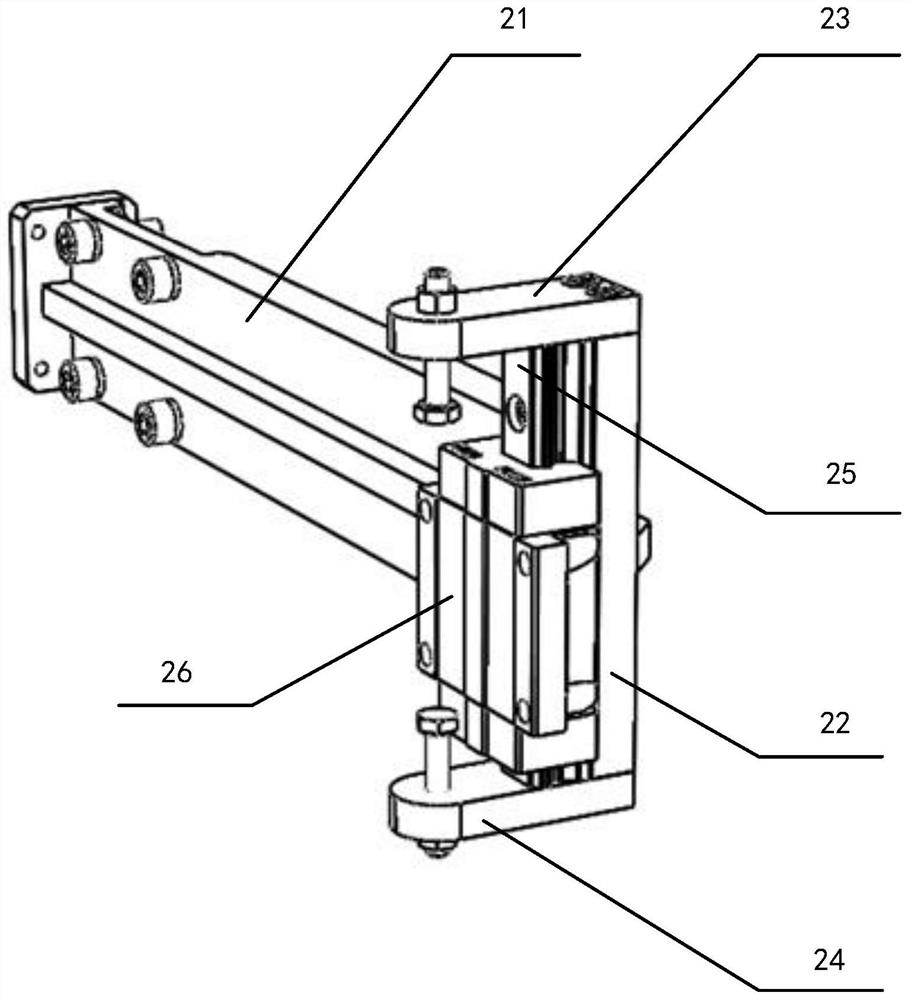

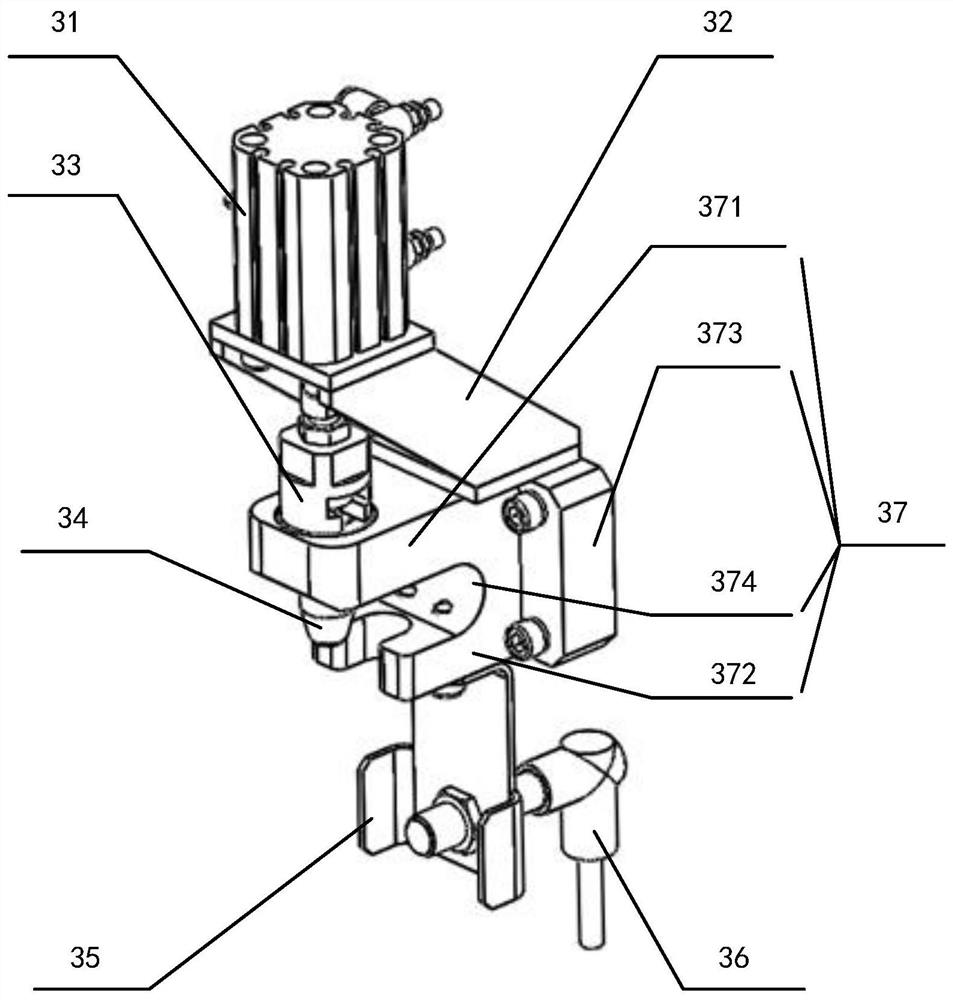

[0027] figure 1 It is a schematic diagram of the overall structure of the flexible fixing mechanism of the workpiece hanger provided by the embodiment o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com