Sleeve mounting machine for building engineering

A technology of construction engineering and installation machine, which is applied in the direction of construction, building structure, and construction material processing, etc., which can solve the problems of low installation efficiency and physical exertion, and achieve the effect of labor-saving installation and improved mobile performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

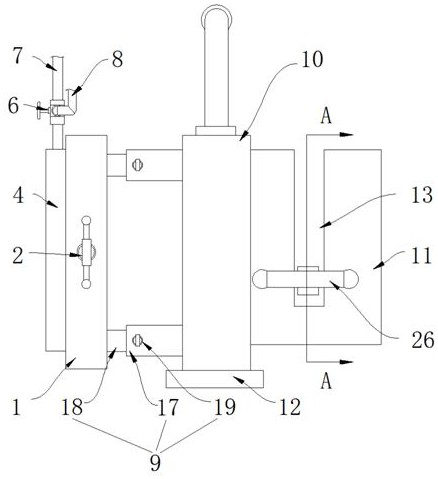

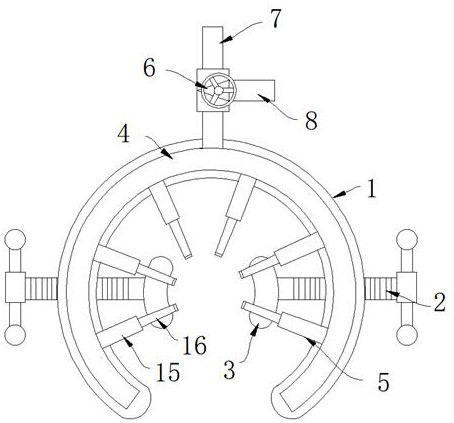

[0027] refer to Figure 1-5 , a sleeve installation machine for construction engineering, including a hydraulic power element and an actuator, the hydraulic power element provides a power source for the actuator, the actuator includes an outer arc ring 1, and the front and rear sides of the outer arc ring 1 are screwed with threads Clamping rod 2, one end of the threaded clamping rod 2 extending to the inside of the outer arc ring 1 is rotatably connected with an extrusion block 3, the left side of the outer arc ring 1 is fixedly connected with an arc-shaped oil pipe 4, and the inner arc surface of the arc-shaped oil pipe 4 A plurality of telescopic columns 5 are installed, and the telescopic columns 5 are composed of a bottom pipe 15 and a movable column 16 plugged in the bottom pipe 15, and the bottom pipe 15 communicates with the inside of the arc oil pipe 4.

[0028] The arc oil pipe 4 communicates with the output pipe 7 and the input pipe 8 of the hydraulic power element ...

Embodiment 2

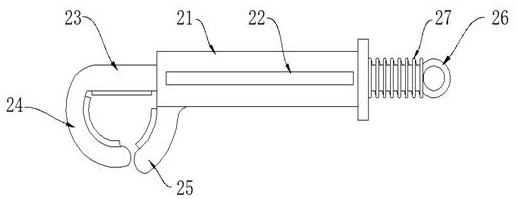

[0032] refer to Figure 6-7 The difference from Embodiment 1 is that the opposite surfaces of the fixed clamp hook 25 and the movable clamp hook 24 are provided with anti-slip rubber pads 35, and the hydraulic power components include a battery 29 fixedly installed on the upper surface of the cart 28, a hydraulic oil pump 30 and a storage battery. Oil tank 31, battery 29 are electrically connected with hydraulic oil pump 30, the output end of hydraulic oil pump 30 communicates with output pipe 7, the input end of hydraulic oil pump 30 communicates with oil storage tank 31, and the interior of input pipe 8 communicates with oil storage tank 31.

[0033] The surface of the output pipe 7 connected to the hydraulic oil pump 30 is provided with a control valve 32, the upper surface of the cart 28 is provided with a riser 33, the left side of the riser 33 is provided with a push handle, and the right side of the riser 33 is provided with a top plate 34, and The lower surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com