Solid waste and alkali liquor circulating desulfurization and decarburization system and working method thereof

A solid waste and working method technology, applied in the petroleum industry, gas fuel, fuel, etc., can solve the problems of natural gas purification reaching the pipeline transportation standard, adding traditional treatment technology, and poor stability of membrane performance, etc., to facilitate the diffusion process , Improve the reaction rate, low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, and its content is explanation of the present invention rather than limitation:

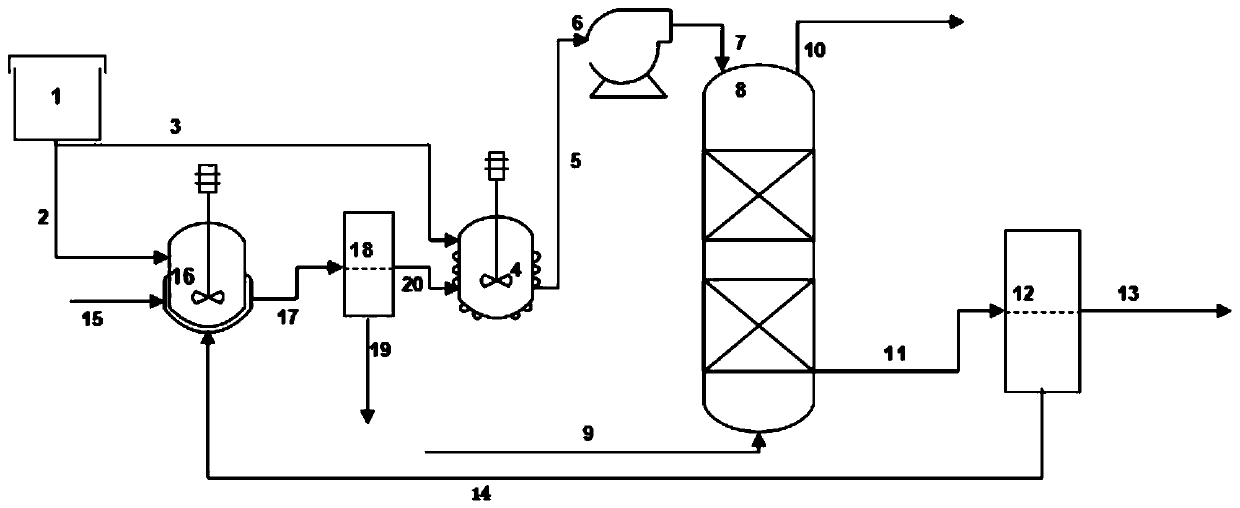

[0031] like figure 1, the solid waste and lye circulating desulfurization and decarbonization system of the present invention, the outlet of the basic oxide solid waste feeding device 1 is respectively connected to the solid inlet of the stirring device 4 through the first conveying branch 3, and the second conveying Branch 2 is connected with the solid inlet of lye regeneration reaction device 16; the liquid inlet of lye regeneration reaction device 16 is connected with lye liquid inlet pipe 15, and the outlet of lye regeneration reaction device 16 passes through the second slurry delivery pipe 17 and The inlet of the second solid-liquid separator 18 is connected, and the solid outlet of the second solid-liquid separator 18 is connected with the first solid dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com