Improved rotary drilling machine coring drilling tool

A rotary excavator, an improved technology, applied to drilling tools, rotary drilling rigs, earthwork drilling and mining, etc., can solve problems such as shedding and drilling tool wear, and achieve the effect of effective shedding and reducing sloshing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

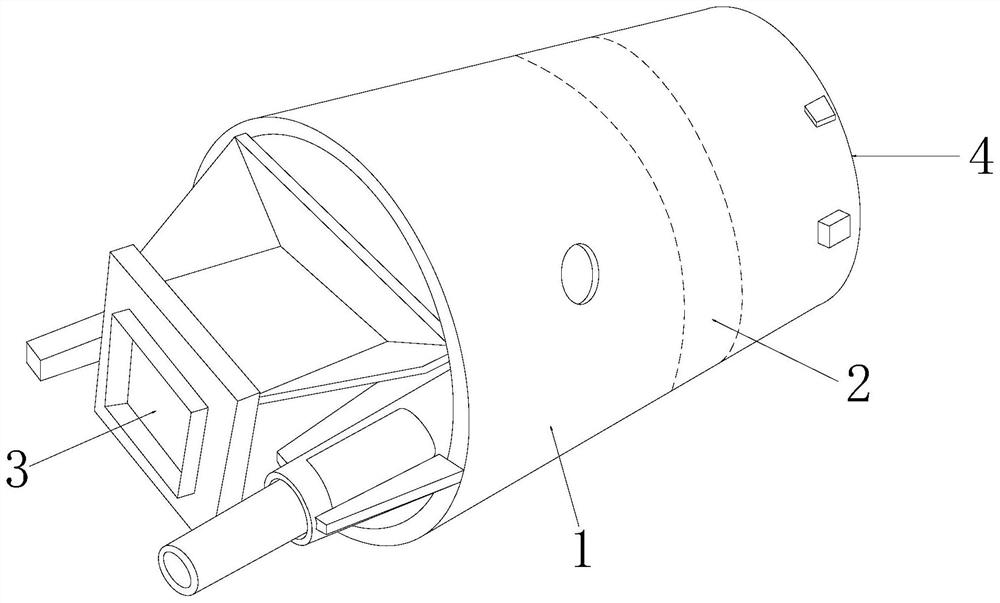

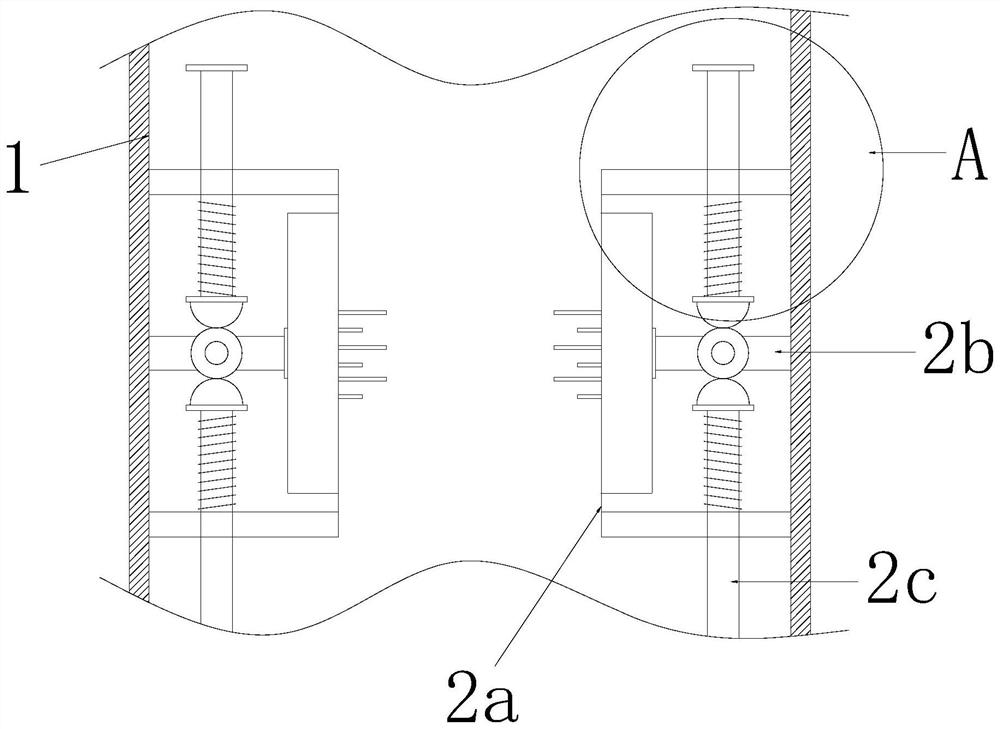

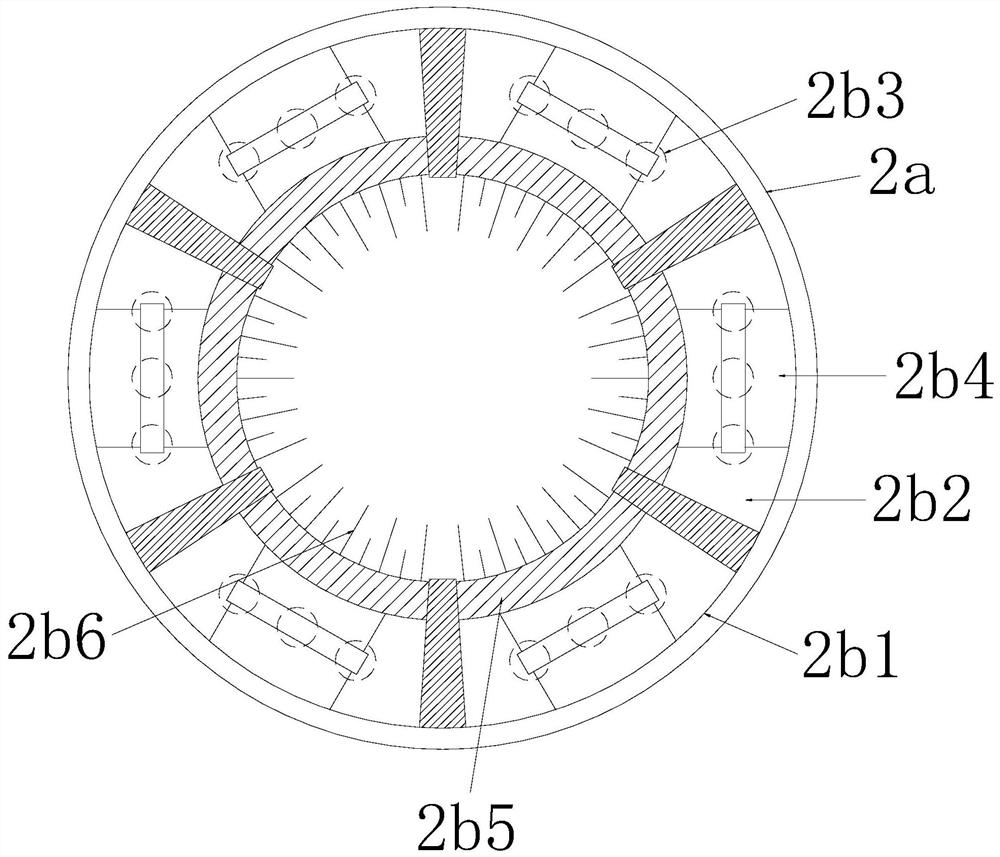

[0029] Such as Figure 1-Figure 6 As shown, the present invention provides a technical scheme of an improved rotary excavator rock drilling tool:

[0030] Such as Figure 1-Figure 2 As shown, an improved rock-taking drilling tool for rotary excavator has a structure including a drill barrel 1, an inner and outer breaking device 2, a fastening sleeve 3, and a tooth plate 4. The inner and outer breaking devices 2 are arranged on the drill The middle part of the inner wall of the tool barrel 1 is connected by electric welding. The fastening sleeve 3 is arranged on the upper end of the drill barrel 1 and connected vertically by electric welding. The tooth digging plate 4 is arranged on the lower surface of the drill barrel 1 and connected by electric welding. , the internal and external breaking device 2 includes a ring frame 2a, a sliding breaking mechanism 2b, and a pounding structure 2c, the sliding breaking mechanism 2b is arranged inside the ring frame 2a and connected by el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com