Method and system for diagnostic testing of engine crankshaft/camshaft synchronous signal

A diagnostic test and synchronous signal technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of many contents and long time consumption, and achieve the effect of reducing infeasibility, saving manpower and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

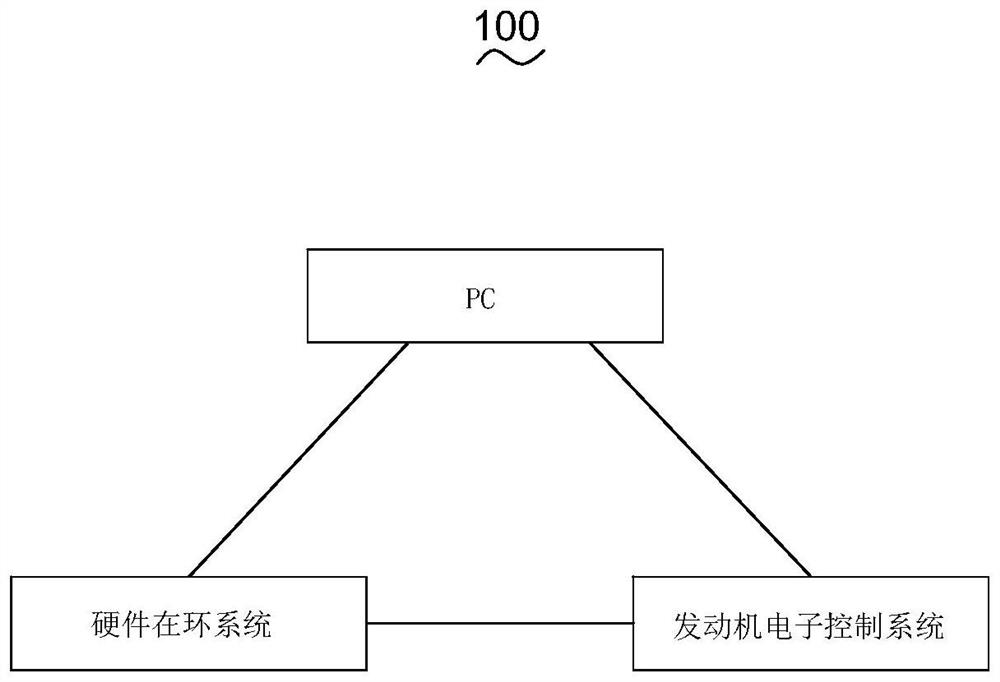

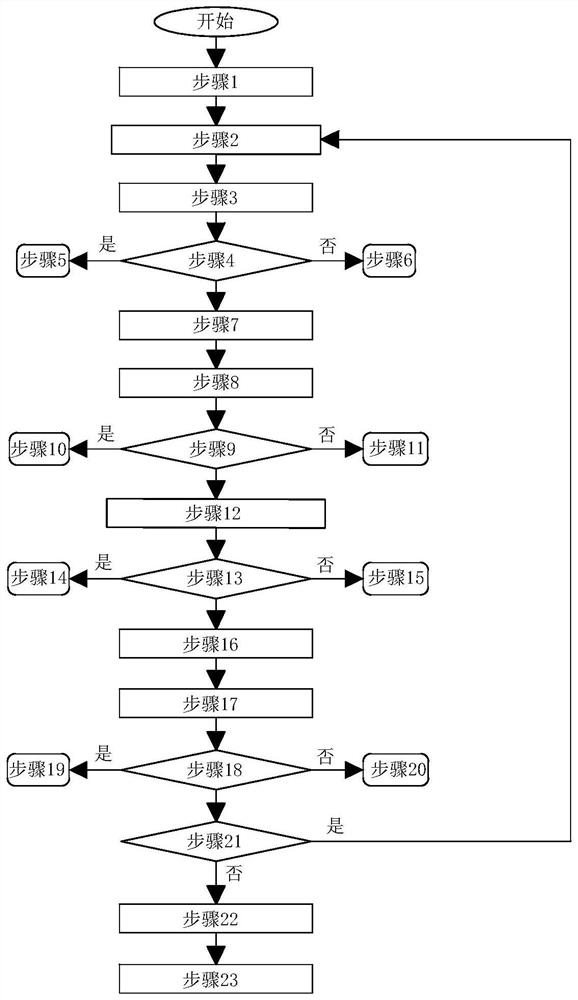

[0051]In the present invention, by writing relevant automatic test scripts and loading them into matching automatic test software tools, the control hardware-in-the-loop system outputs fault signals of various crankshaft position sensors and camshaft position sensors respectively, and then, the engine electronic control system respectively collects These failure signals are detected, and the failure flag variables corresponding to each failure signal are respectively set in the relevant software testing tools, and after several driving cycles, the engine failure indicator signal will also be set. The hardware-in-the-loop system will then resend the normal signals from the crankshaft position sensor and the camshaft position sensor, the previously set fault flag variable will be reset, and after several driving cycles, the engine fault indicator light signal will be reset reset. In the automatic test script, it will judge the setting and reset of the fault flag variable corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com