A three-dimensional structure composite metal lithium negative electrode and preparation method thereof

A composite metal, three-dimensional structure technology, applied in the direction of negative electrodes, structural parts, battery electrodes, etc., can solve problems such as difficult to avoid dendrites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

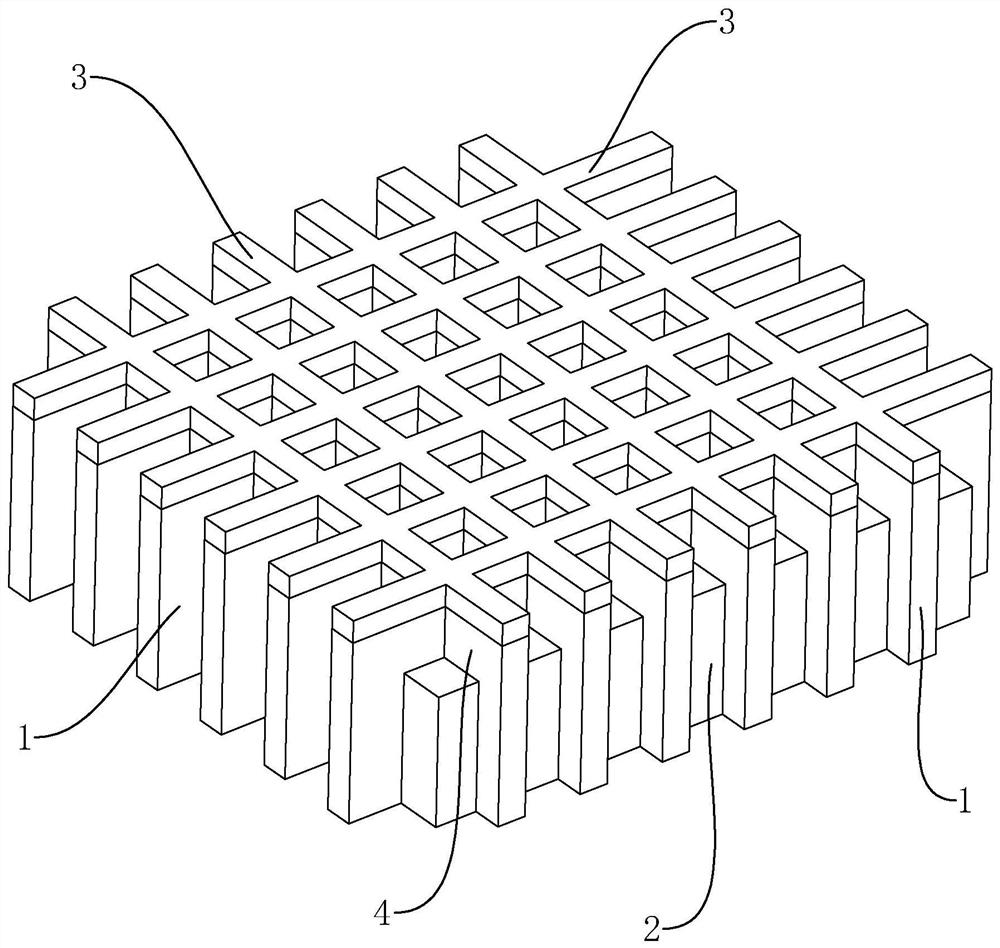

[0047] refer to figure 1 , is a three-dimensional structure composite metal lithium negative electrode disclosed in the present invention, comprising a metal mesh layer, the material of the metal mesh layer is copper; the mesh shape of the metal mesh layer is circular, and the aperture of the mesh is 0.01 μm.

[0048] like figure 1 As shown, the three-dimensional structure composite metal lithium negative electrode further includes a metal lithium layer, the lower part of the metal mesh layer is inserted into the metal lithium layer, and the thickness of the metal mesh layer penetrated in the metal lithium layer is the same as the thickness of the metal lithium layer, and the metal lithium layer has the same thickness. The thickness of the layer is (the surface capacity value of the positive pole piece × (1-Coulomb efficiency) × 5 × the expected number of cycles + (0 to 10)) μm, so that the lithium of the metal lithium layer preset in the lower part of the metal mesh layer can...

Embodiment 2

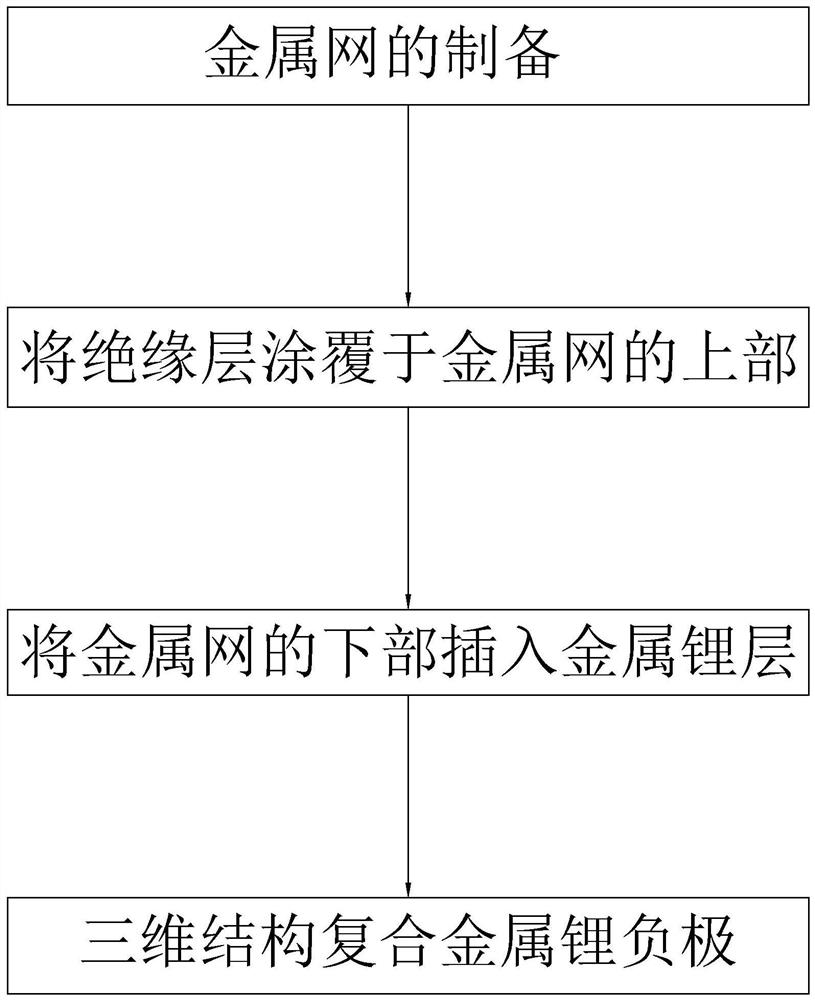

[0057] The difference from Example 1 is that, as figure 2 As shown, a preparation method of a three-dimensional structure composite metal lithium negative electrode, the preparation process includes:

[0058] Preparation of metal mesh layer; at least one method of laser etching, chemical etching, and physical weaving;

[0059] Coat the insulating layer on the upper part of the metal mesh layer; prepare the components of the insulating layer and the solvent into a glue solution, and apply the glue solution on the upper part of the metal mesh layer with a scraper or spin coater, and then apply the glue to the top of the metal mesh layer. The components of the insulating layer are melted and covered on the upper half of the metal mesh layer, the melting temperature is 200°C, and finally cooled to room temperature; the solvent is N-methylpyrrolidone, etc.;

[0060] Insert the lower part of the metal mesh layer into the metal lithium layer; insert the lower part of the metal mesh...

Embodiment 3

[0064] The difference from Example 1 is that, as figure 2 As shown, a preparation method of a three-dimensional structure composite metal lithium negative electrode, the preparation process includes:

[0065] Preparation of metal mesh layer; at least one method of laser etching, chemical etching, and physical weaving;

[0066] Coat the insulating layer on the upper part of the metal mesh layer; use a powder beater to beat the components of the insulating layer into dry fine powder with a particle size of 500nm, and then immerse the upper part of the metal mesh layer to generate electrostatic adsorption, so that the components of the insulating layer Adsorbed to the upper part of the metal mesh layer, and then heated by a box furnace to melt the components of the insulating layer and cover the upper half of the metal mesh layer, the melting temperature is 500 ℃, and finally cooled to room temperature;

[0067] Insert the lower part of the metal mesh layer into the metal lithi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com