A large cabin simulation chassis docking device and method

A docking device and cabin technology, applied in the direction of workpiece clamping devices, manufacturing tools, workbenches, etc., can solve the problems of complex operation, inability to solve the docking of cabins, assembly and transfer, etc. The structure is simple and the effect of reducing the installation and adjustment cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

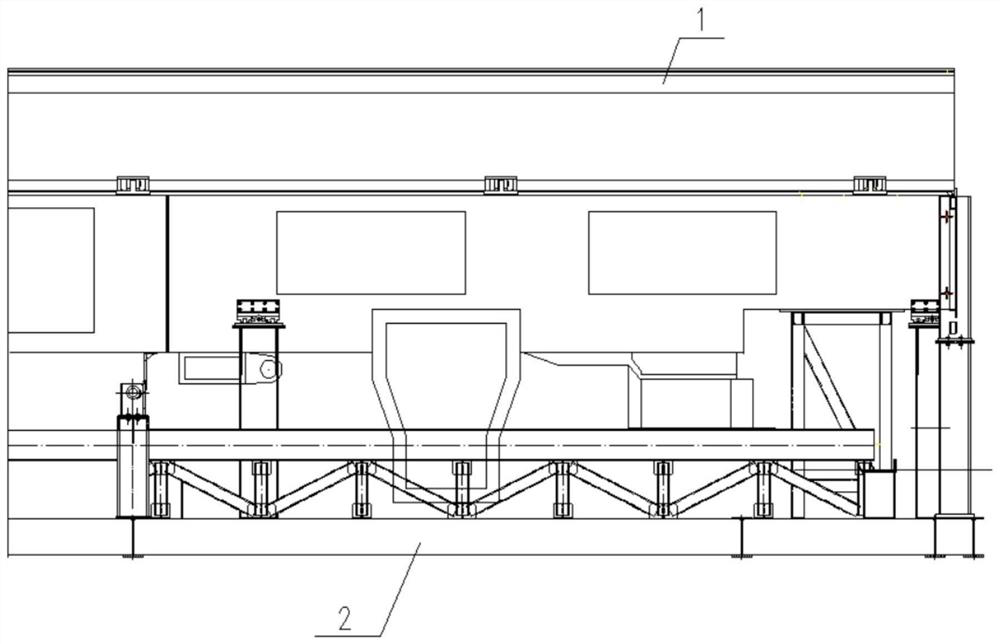

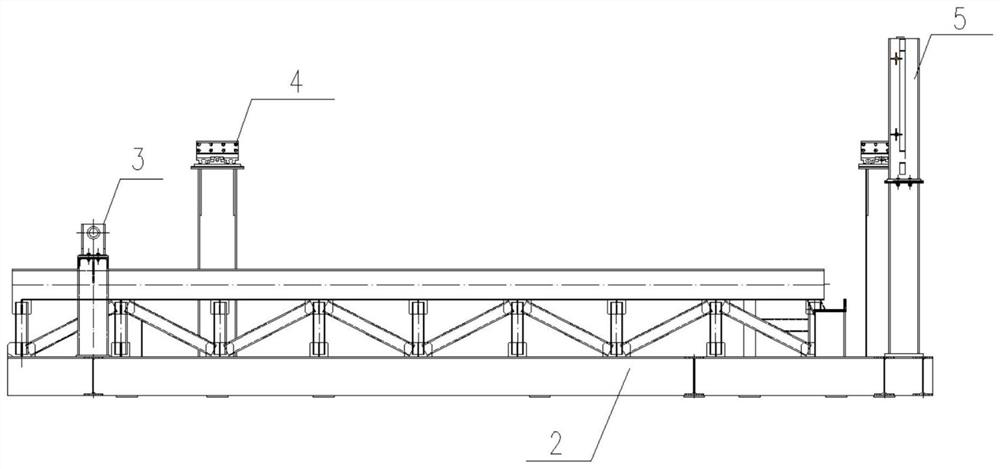

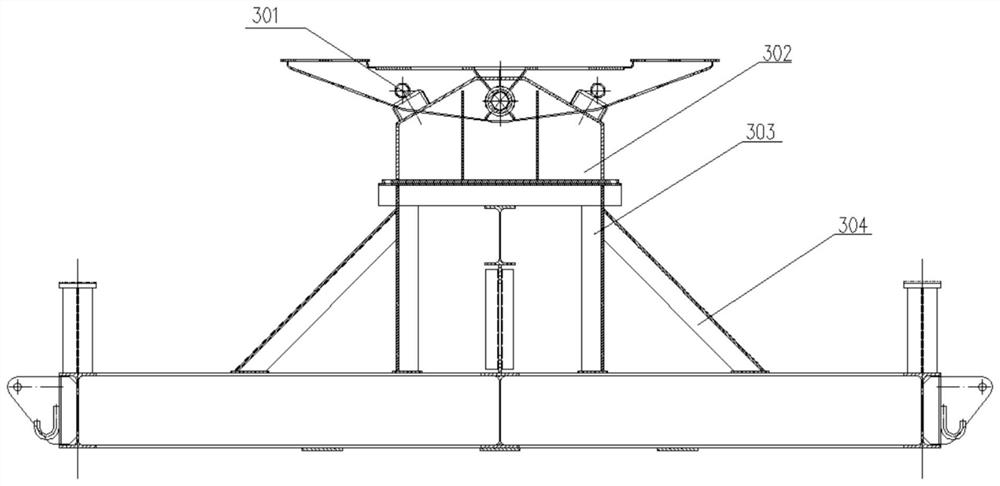

[0031] Figure 1-Figure 5It is a docking device for simulating the chassis of a large cabin. The front end of the large cabin 1 is hoisted to the corresponding position of the frame 2 as required and placed. Through the front left and right clamping devices 4, the front end of the large cabin 1 is determined to be on the frame 2. Accurate position, drill the connecting hole between the front cabin end and the large cabin body 1 support, and fasten.

[0032] Place the left and right rear cabin sections of the large cabin body 1 on the corresponding positions of the vehicle frame 2, adjust their left and right, front and rear relative positions, and determine the exact position of the left and right rear cabin sections on the vehicle frame 2 through the left and right clamping devices 4 of the rear section , Adjust the rear cabin top tightening device welding at the rear of the frame 5, and tighten the inner sides of the left and right rear cabin sections.

[0033] After the ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com