A Shot Peening Process for Surface Strengthening of Nuts

A surface strengthening and nut technology, which is applied in the shot peening process of nut surface strengthening, can solve the problems of poor roughness, dry shot peening, uneven surface, etc., achieve uniform residual stress, increase service life, and low surface roughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

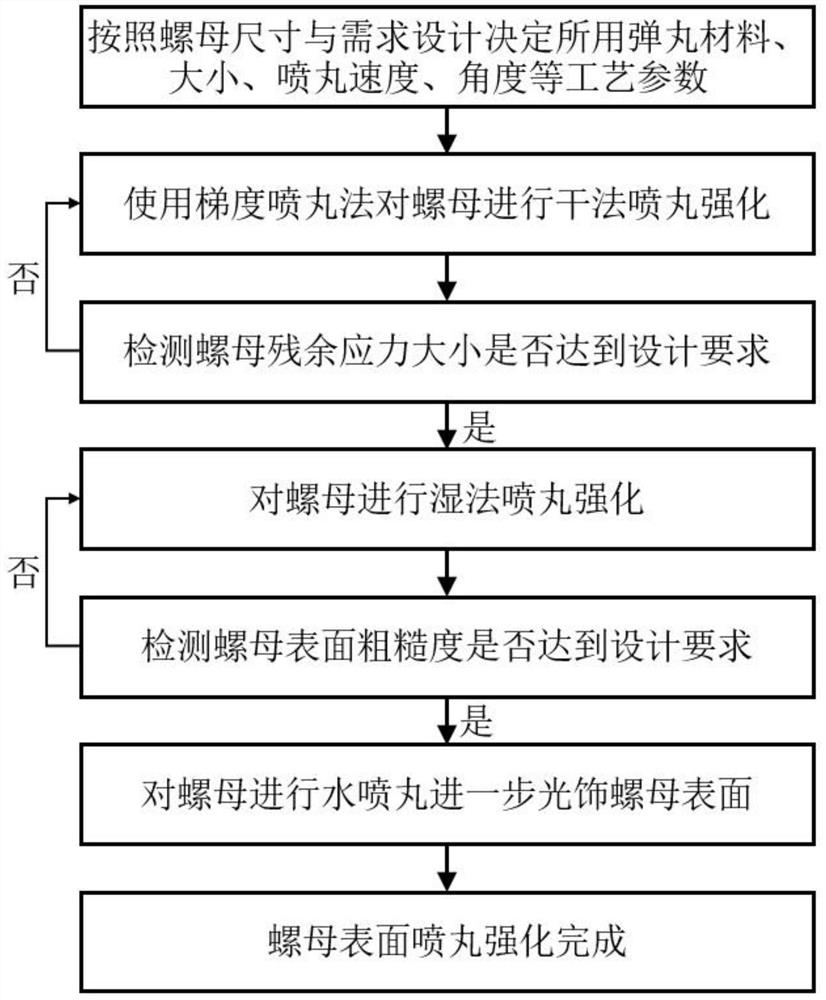

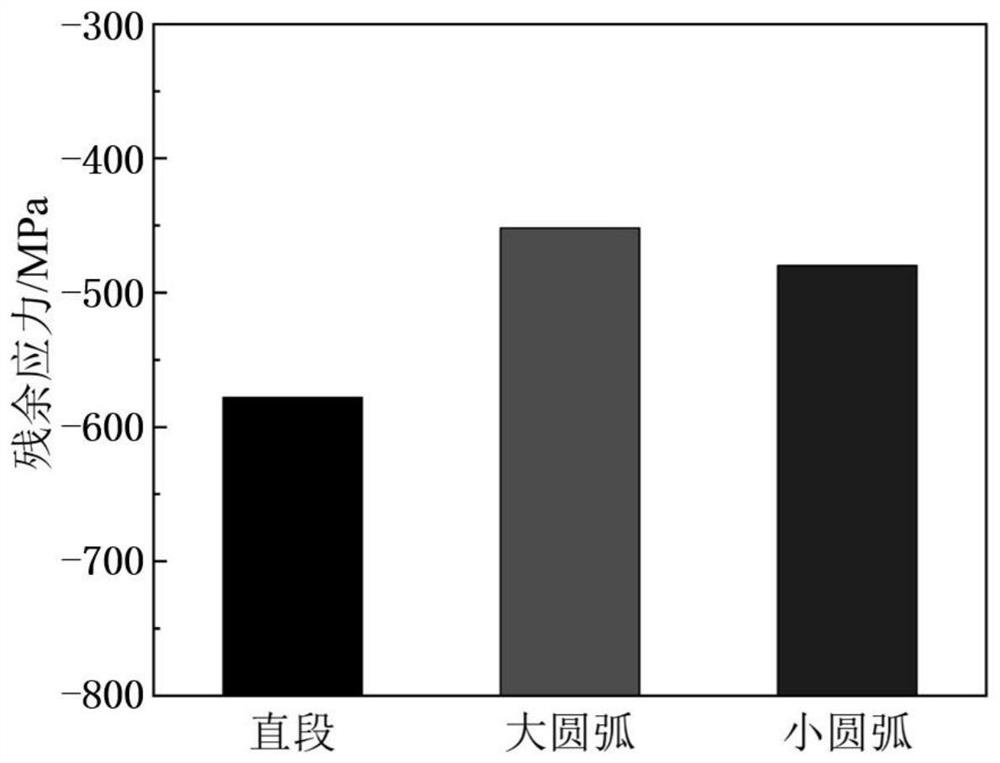

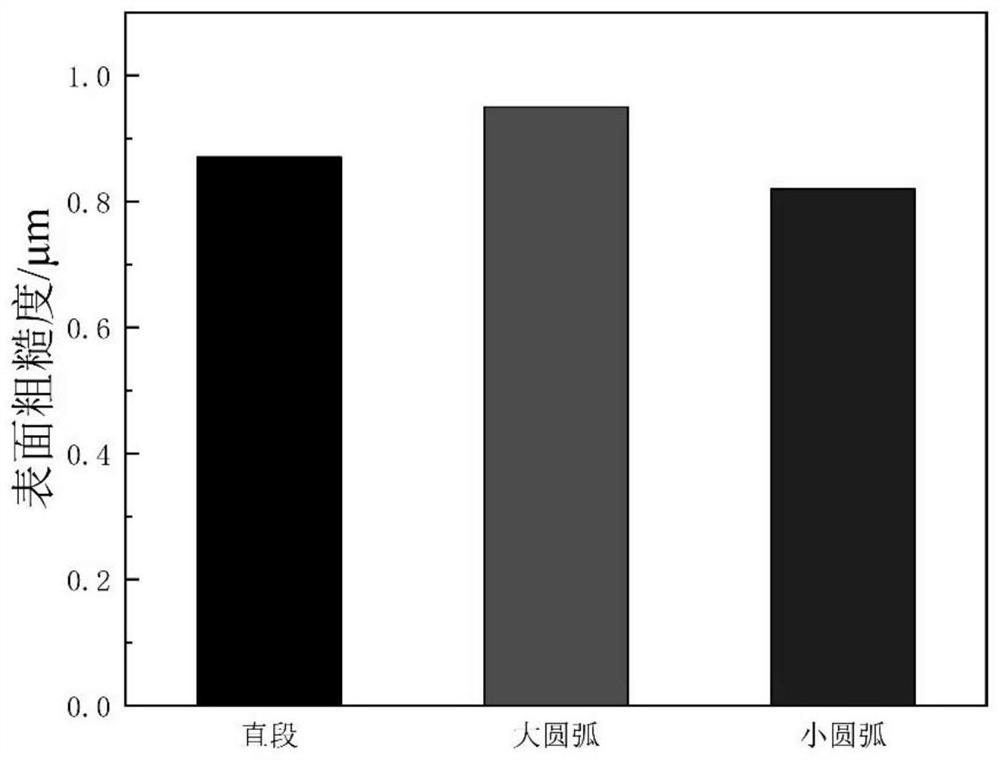

[0029] Such as figure 1 with Figure 4 As shown, S1: According to the design of the geometric structure of the nut, divide the straight section c, small arc a, and large arc b into three sections to determine the technological parameters of the shot material, size, shot peening speed, and angle used;

[0030] S2: Dry Gradient Shot Peening: According to the straight section c, small arc a, and large arc b of the geometric structure of the nut, three types of projectile ceramic shot are selected to perform dry gradient shot peening on the nut, using conventional compressed air as the power, Bombard the workpiece surface with pellets;

[0031] S3: Detect the residual stress on the surface of the nut: After a period of dry shot peening, check whether the residual stress on the surface of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com