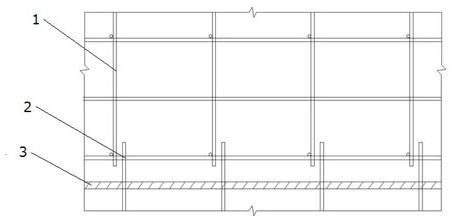

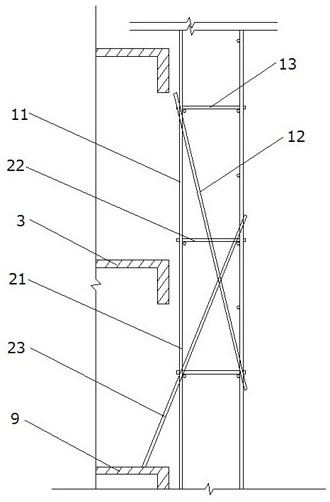

Inverted type cantilever scaffold erecting method

A technology for cantilevering scaffolding and scaffolding, which is applied to the attachment of scaffolding, the connection of scaffolding, and the scaffolding supported by house structure, etc., to achieve the effect of ensuring safety performance, speeding up construction progress, and reducing welding open flame operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0040] The fourth bid section of the construction and installation project of a resettlement community, the construction area of the project is 56963.47 m2, and the cost is 114.1933 million yuan. There is one basement floor and 24 floors underground. The 1-3 floor podium adopts ordinary floor-to-ceiling scaffolding, and the 4th floor begins to use 16# I-beam cantilevered scaffolding. This project adopts the construction technology of inverted cantilevered scaffolding, and the construction quality and safety are reliably guaranteed, without any size safety. The accident occurred, and the construction period was shortened by about 6 days compared with the conventional construction technology, and the cost of materials and labor was reduced by 27,000 yuan, and the economic benefits were obvious.

example 2

[0042]The first phase of a school renovation and expansion project, with a total construction area of about 100075.91m2. Among them, the comprehensive building (15#) and the shift building (23#) are high-rise buildings. During the main construction, the cantilevered scaffolding will be erected in three sections from the second floor above. . The cantilevered scaffolding adopts the construction technology of inverted cantilevered scaffolding, which avoids the lack of protection of the outer frame when the cantilevered scaffolding is erected, eliminates potential safety hazards, and has no safety accidents during the construction process, which has won unanimous praise from the construction and supervision units. Compared with the conventional construction technology, the construction period is shortened by about 7 days, and the cost of materials and labor is reduced by 32,000 yuan, and the economic benefits are obvious.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com