Tunnel smoke exhaust system and tunnel

A smoke exhaust system and smoke exhaust channel technology, which is applied in mine/tunnel ventilation, pump control, mining equipment, etc., can solve the problems of large air leakage, large attenuation, and delayed smoke exhaust response, and achieve the effect of improving the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a tunnel smoke exhaust system, which can be applied to tunnels in mountainous areas, underground, and under the sea. Well Tunnel. A long tunnel is a tunnel with a length of more than 5 kilometers. The above-mentioned tunnel can be a road tunnel, a railway tunnel or an urban rail vehicle tunnel. This embodiment only takes a road tunnel as an example to describe the smoke exhaust system in detail. Those skilled in the art can directly apply the technical solution provided by this embodiment to other type of tunnel, or apply the technical solution provided in this embodiment to other types of tunnels after adaptive modification.

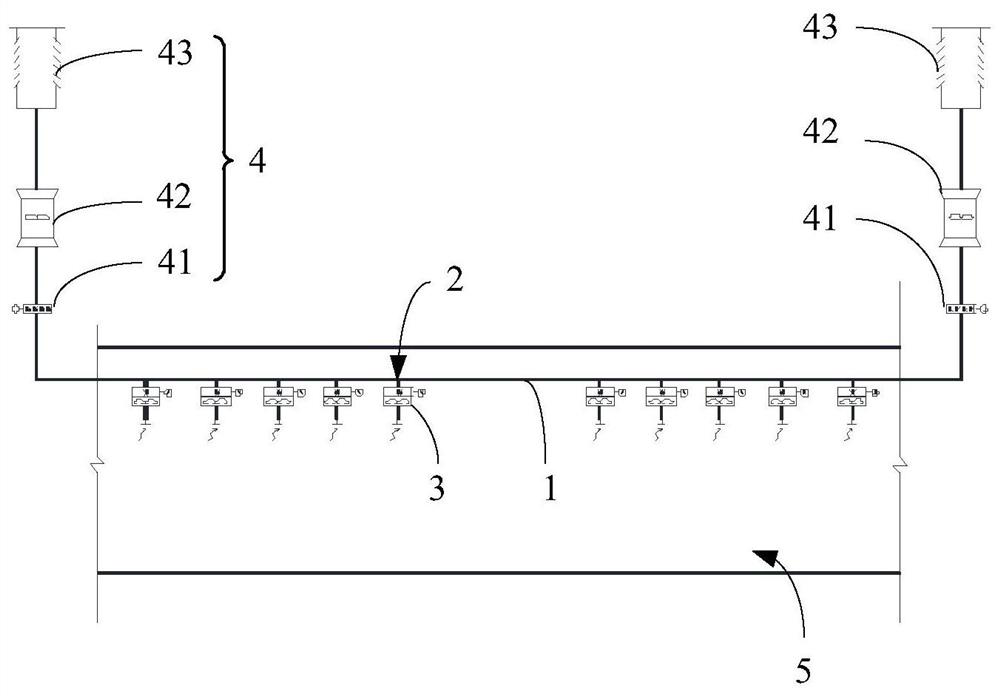

[0036] figure 1 It is an overall schematic diagram of the application of the tunnel smoke exhaust system provided in Embodiment 1 of the present application to a tunnel. Such as figure 1 As shown, this embodiment provides a tunnel smoke exhaust system, including: a smoke exhaust channel 1 , a smoke exhaust port 2 , an...

Embodiment 2

[0049] This embodiment provides a specific implementation of the tunnel smoke exhaust system on the basis of the above embodiments.

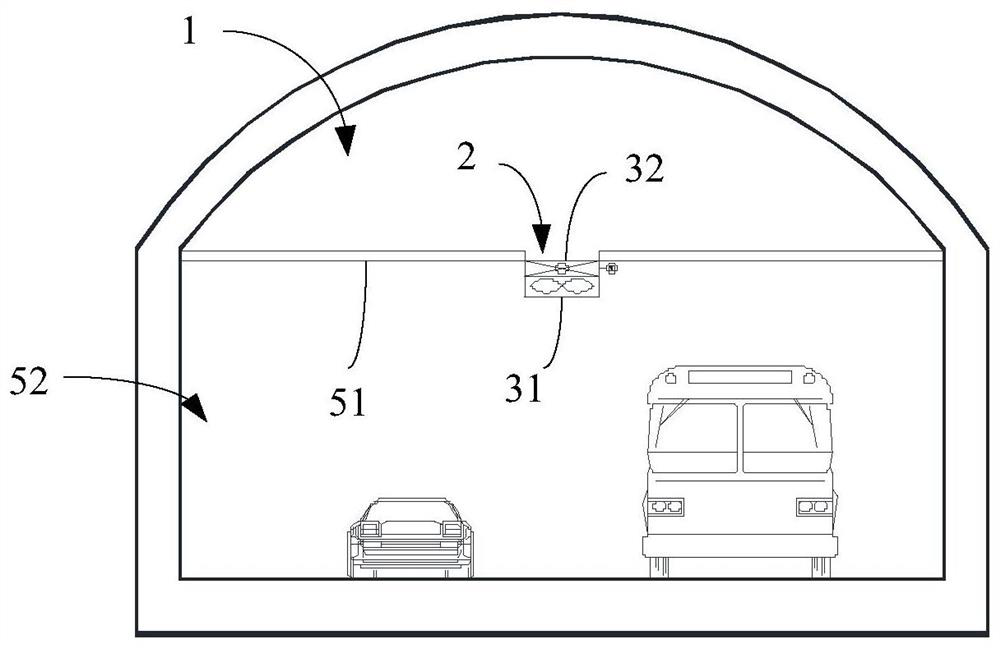

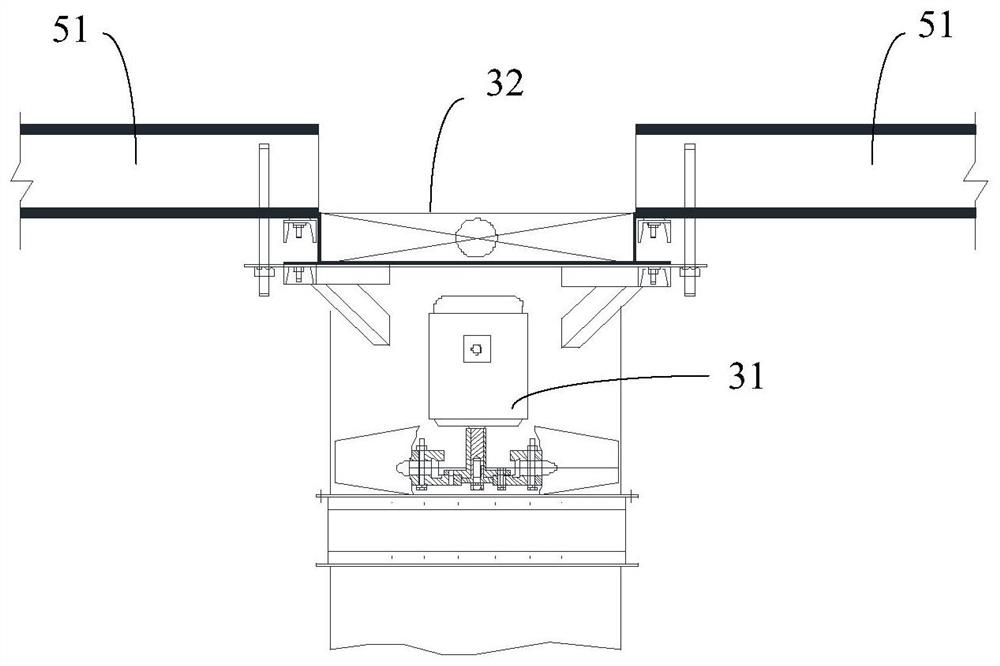

[0050] figure 2 The tunnel section view provided for Embodiment 2 of the present application, image 3 A schematic structural diagram of an internal smoke exhaust fan and an internal smoke exhaust valve provided at the smoke exhaust port of the tunnel smoke exhaust system provided in Example 2 of the present application. Such as figure 2 As shown, a partition wall 51 is provided above the tunnel 5 provided in this embodiment, and the partition wall 51 extends along the horizontal direction and is formed between the two side walls of the tunnel. The space below the partition wall 51 is the driving passage 52 , and the space above the partition wall 51 is the smoke exhaust passage 1 .

[0051] A plurality of smoke outlets 2 are opened on the partition wall 51, and the plurality of smoke outlets 2 are arranged at intervals along the length dir...

Embodiment 3

[0061] This embodiment is based on the above-mentioned technical solution, and provides another implementation manner in which the smoke exhaust system is applied in a tunnel.

[0062] Figure 4 The tunnel section view provided for the third embodiment of the present application, Figure 5 A structural schematic diagram of an internal smoke exhaust fan and an internal smoke exhaust valve provided at the smoke exhaust port of the tunnel smoke exhaust system provided in Example 3 of the present application. Such as Figure 4 As shown, the partition wall 51 extends in the vertical direction and is located between the top wall and the bottom wall of the tunnel 5 . There are two partition walls 51 arranged side by side in the middle of the tunnel 5 . A smoke exhaust channel 1 is formed between the two partition walls 51 , the left side of the left partition wall 51 is the driving passage 52 , and the right side of the right partition wall 51 is the driving passage 52 . The driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com