Liquid level stabilizing structure for controlling electrode water level tank in semi-immersed electrode boiler

An electrode boiler, semi-submerged technology, applied in the direction of electrode boilers, water supply control, steam boilers, etc., can solve the problems of different contact areas between electrodes and electrolyte solutions, the water surface of the inner cylinder is prone to waves, and reduce the service life of boilers. Increase heating effect, simple structure, reduce the effect of boiler shutdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

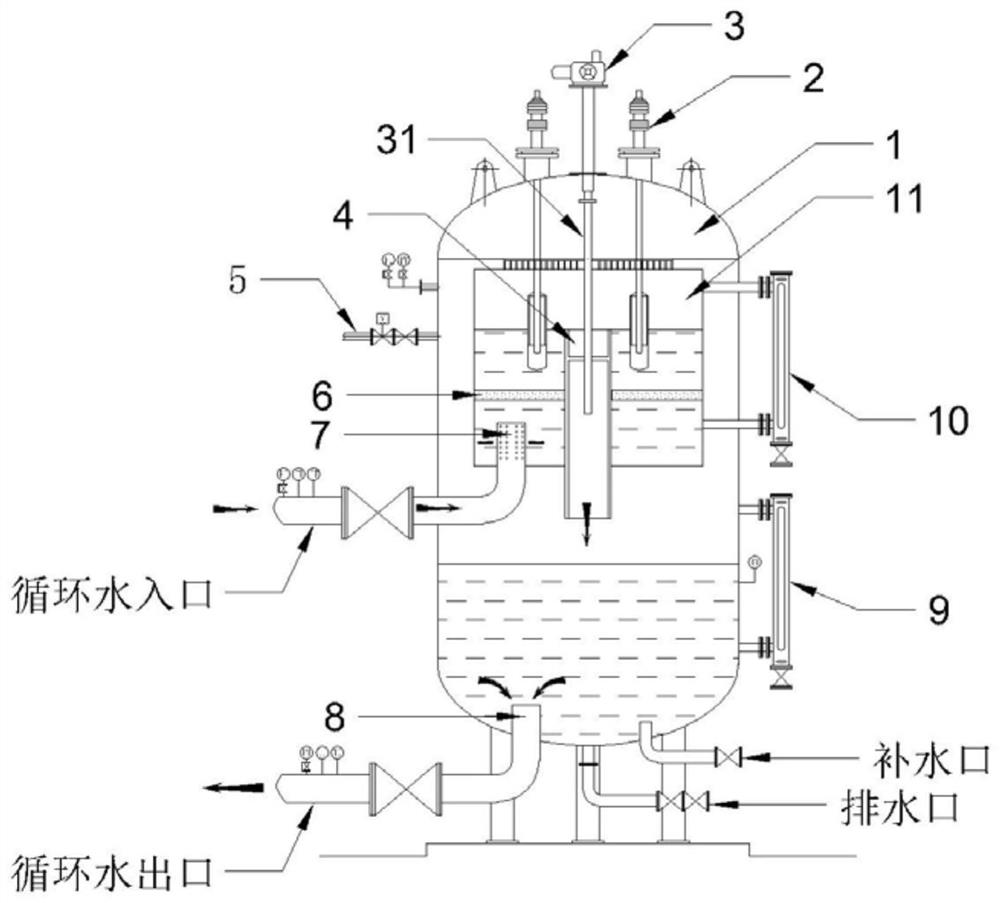

[0027] An embodiment, a structure for controlling the level stability of the electrode water level tank in a semi-submerged electrode boiler, see Figure 1-3 As shown, including the boiler body 1;

[0028] The inner upper end of the boiler body 1 is provided with a boiler inner cylinder 11 fixedly installed therewith;

[0029] The top of the boiler body 1 is provided with several electrodes 2, and the electrodes 2 extend through the part of the boiler body 1 to the inside of the boiler inner cylinder 11;

[0030] The middle end of the boiler inner cylinder 11 is provided with an overflow pipe 4 which is movable socketed therewith, the top end of the overflow pipe 4 communicates with the boiler inner cylinder 11, and the bottom end of the overflow pipe 4 communicates with the boiler body 1;

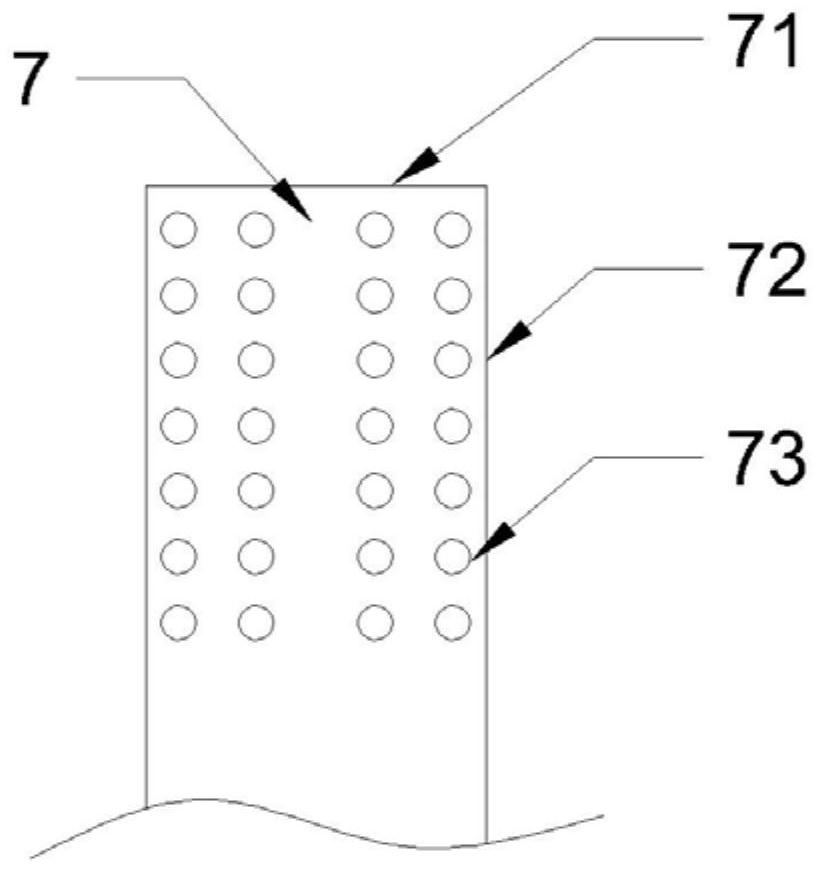

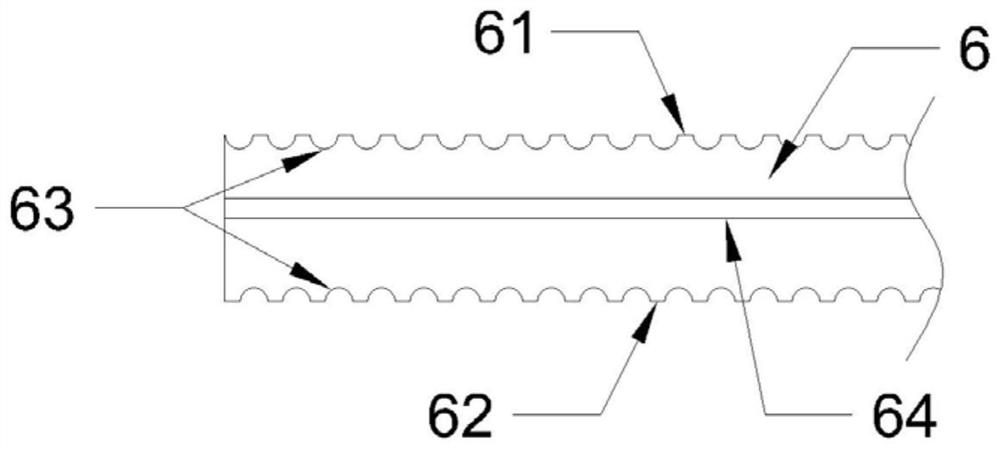

[0031] The bottom end of the boiler inner cylinder 11 is provided with a water inlet pipe 7 connected to it, and the boiler inner cylinder 11 above the water inlet pipe 7 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com