Numerically-controlled machine tool spindle health degree quantitative evaluation method

A technology for health degree and quantitative evaluation, applied in complex mathematical operations, computer-aided design, geometric CAD, etc., to achieve the effect of simple operation, avoidance of losses, and convenient parameter modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below through specific embodiments in conjunction with the accompanying drawings. These embodiments are only used to illustrate the present invention, and are not intended to limit the protection scope of the present invention.

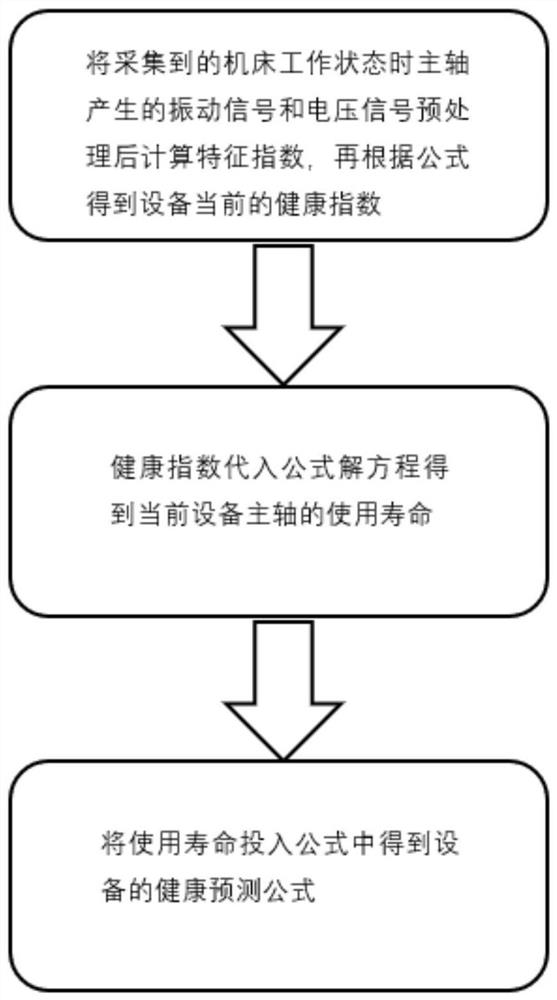

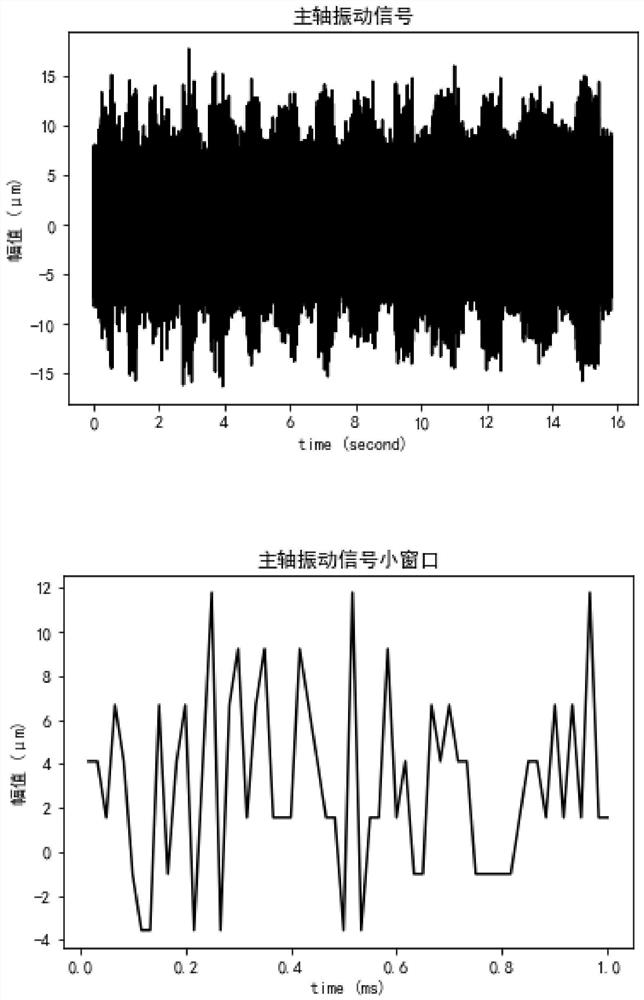

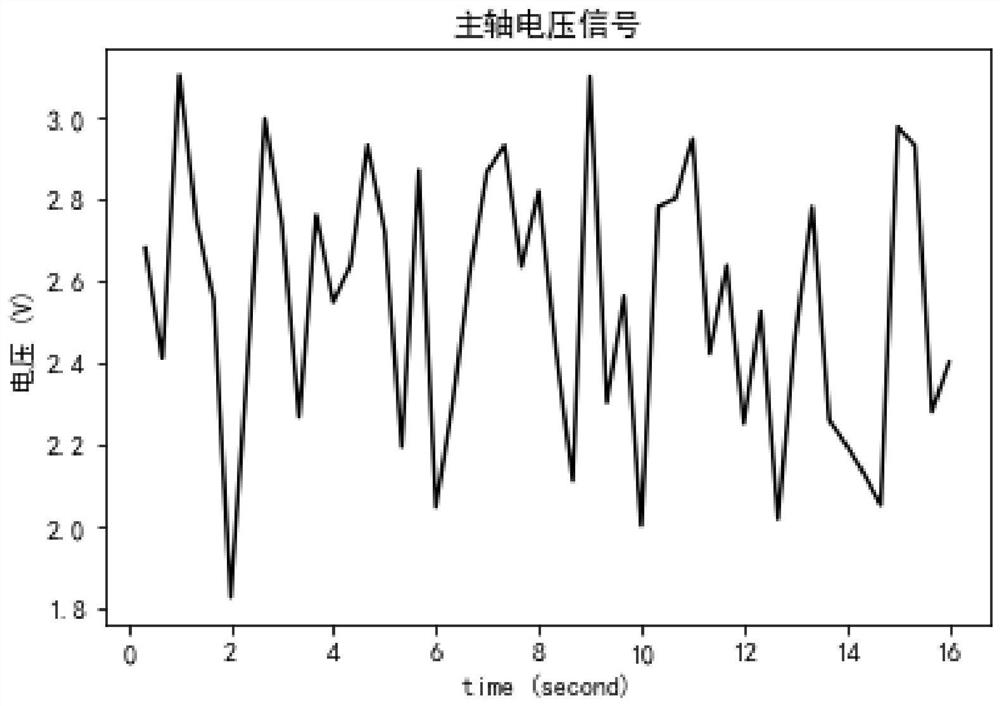

[0040] S1, calculate the characteristic index after removing the noise from the collected vibration signal and voltage signal generated by the spindle in the working state of the machine tool, and then obtain the current health index of the equipment according to the formula;

[0041] S2, substituting the health index into the formula to solve the equation to obtain the service life of the main shaft of the current equipment;

[0042] S3, putting the service life into the formula to obtain the health prediction formula of the equipment.

[0043] In said step S1, C S = 1.2C P =1.71C f =2.46C St = 0.43 C = 3.67 N = 2.5

[0044] Get AI=3.6 EI=4.1 SI=2.01 RI=1.53, substitute into the formula, s=A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com