Patch type fuse applied to switching power supply

A technology of switching power supply and fuse, which is applied in the direction of circuits, electrical components, emergency protection devices, etc., can solve the problems of not being able to fuse quickly and cleanly, affect the life of PCB, waste PCB space, etc., achieve fast and clean fusing ability, and improve service life , Reduce the effect of application space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

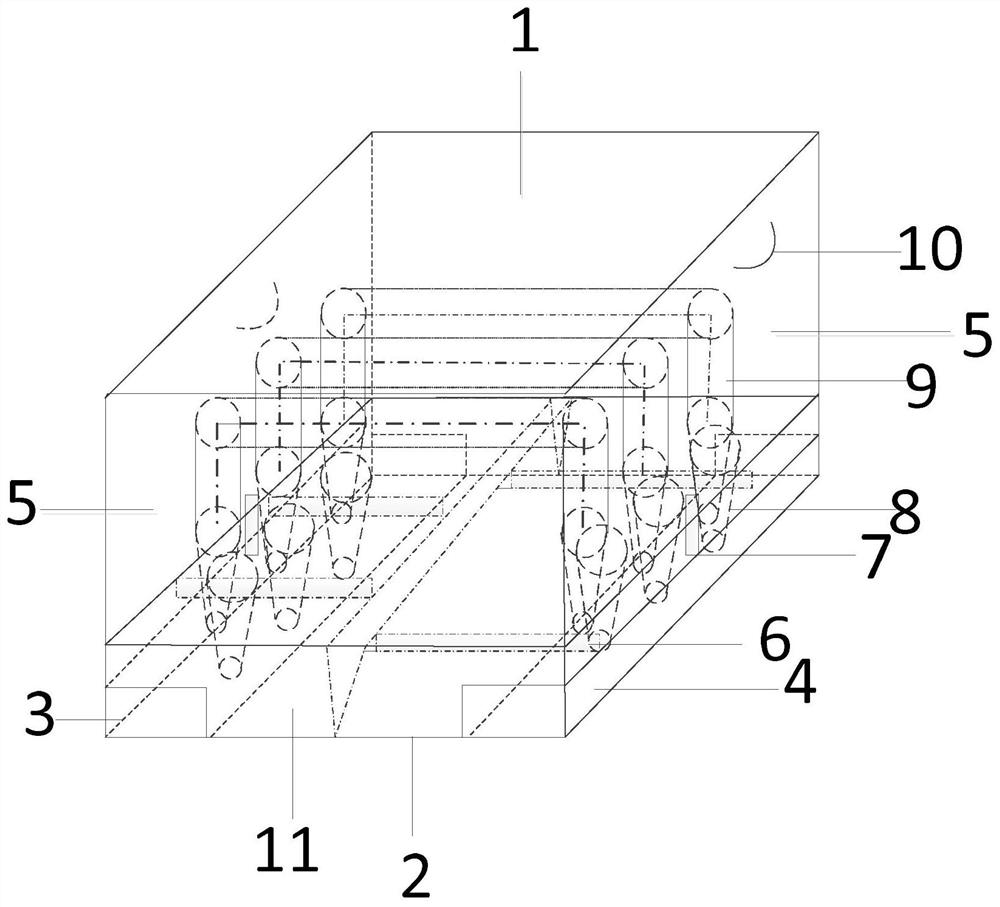

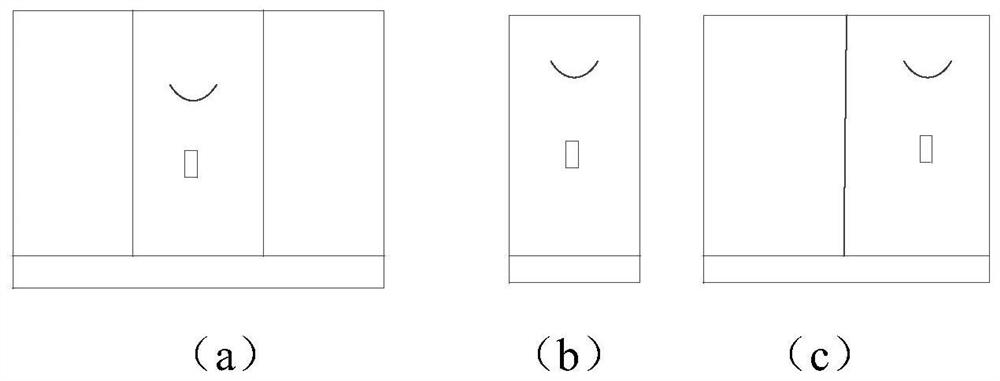

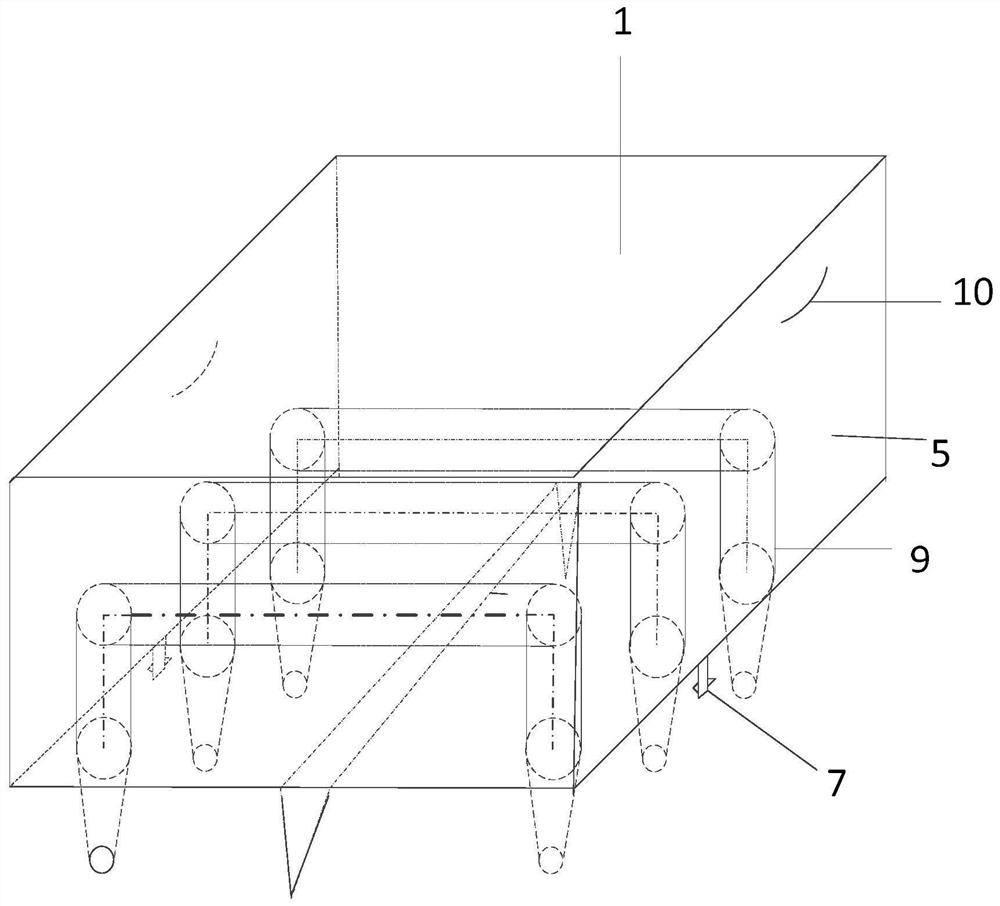

[0038] like figure 1 As shown, a chip fuse applied to a switching power supply includes a fuse replacement part 5 and a fuse welding part 11; There are several fuse main bodies 9, which are fixedly installed in the inner cavity of the upper base plate 1; The buckle of the lock 7 is connected to the lower part of the upper substrate 1; The first end surface electrode 3 and the second end surface electrode 4 are respectively fixed on the left and right ends of the lower substrate 2, and are fully or partially exposed to the lower substrate 2; the metal slot 8 is arranged in the lower substrate 2. The upper part of the lower base plate 2, and the number and size are corresponding to the fuse body 9, which is used for inserting the slot body insertion part of the fuse body 9; the card slot of the locking buckle 7 is connected to the lower base pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com