Fan-shaped casting ladle tilting casting machine special for casting production of small castings

A pouring machine and pouring ladle technology, which is used in equipment for feeding molten metal into molds, casting equipment, and casting molten material containers, etc., can solve the problems of inability to control the pouring speed and the pouring is not stable enough, and achieve convenient control of the pouring speed. , strong practicability and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

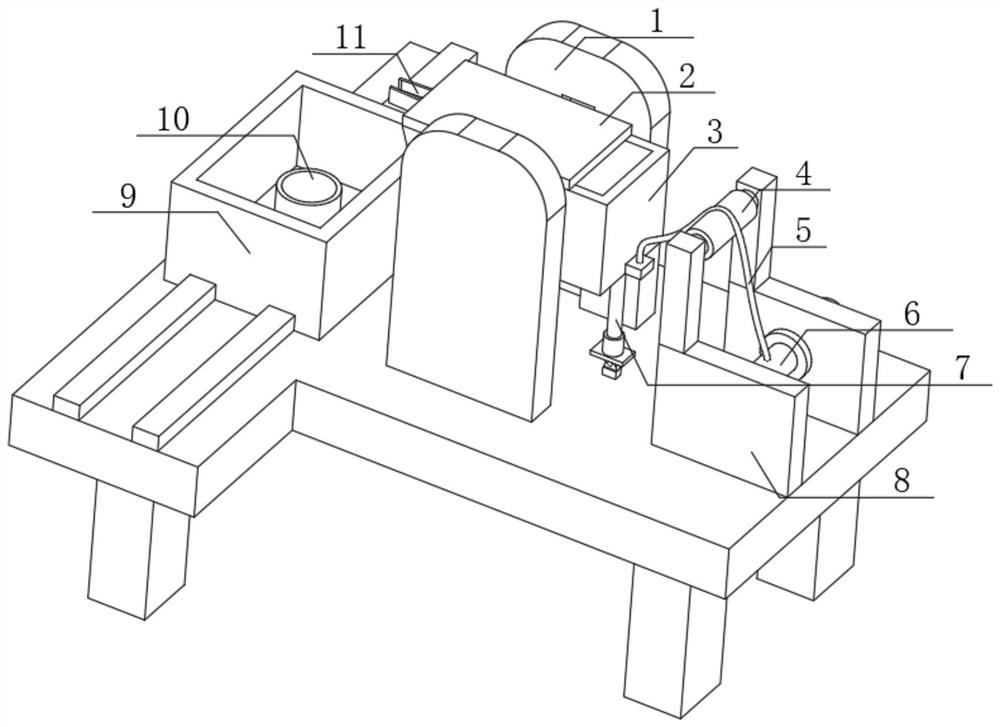

[0022] refer to figure 1 , a fan-shaped ladle tilting pouring machine dedicated to the production of small castings, including a workbench 12, the two sides of the top outer wall of the workbench 12 are fixed with side plates 1 by screws, and the outer walls of the opposite sides of the two side plates 1 are open There is a sliding groove, the inner wall of the sliding groove is fixed with a sliding rail by screws, the inner wall of the sliding rail is slidably connected with a slider, one side of the outer wall of the slider is connected with a ladle 3 through a bearing, and the top outer wall of the ladle 3 is fixed with a ladle by screws The cover 2 and the outer wall of one side of the ladle 3 are fixed with a mounting block by screws, the top outer wall of the mounting block is provided with a bolt connection hole, and the inner wall of the bolt connection hole is bolted with a tension rope 5, and both sides of the top outer wall of the workbench 12 pass through The mount...

Embodiment 2

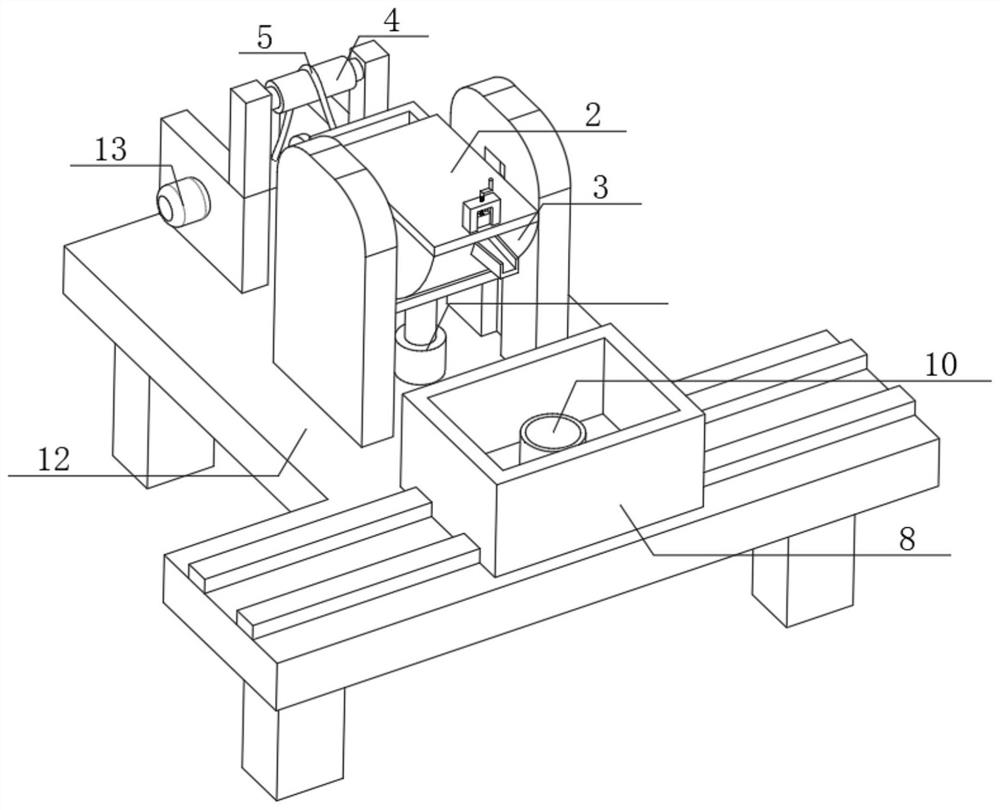

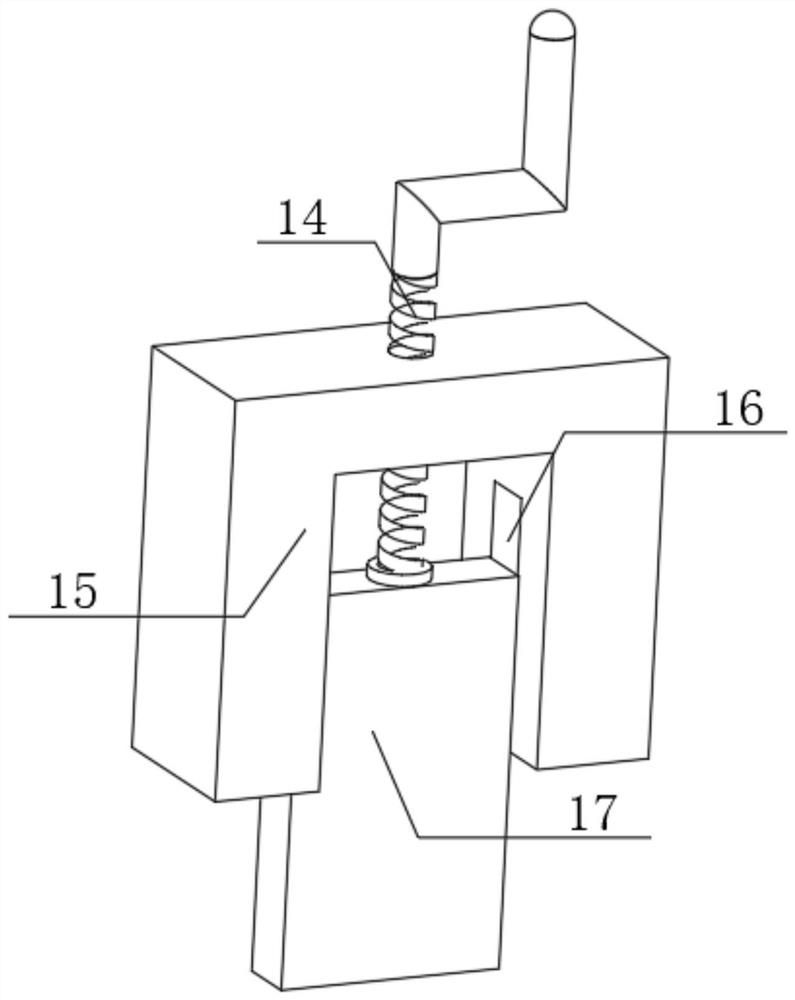

[0030] refer to Figure 2-3 , a fan-shaped ladle tilting pouring machine dedicated to the production of small castings. Compared with Embodiment 1, this embodiment also includes a fixed plate 15 fixed on the top outer wall of the ladle cover 2 by screws, and one side of the fixed plate 15 The outer wall is provided with installation holes, and both sides of the installation hole are provided with chute, the inner wall of the chute is fixed with a slide rail 16 by screws, the inner wall of the slide rail 16 is slidably connected with a sealing plate 17, and the top outer wall of the fixed plate 15 is provided with Threaded hole, the inner wall of the threaded hole is threadedly connected with a threaded rod 14, and one end of the threaded rod 14 is connected with the top outer wall of the sealing plate 17 through a bearing, the top outer wall of the ladle cover 2 has a sliding hole, and the outer wall of the sealing plate 17 is connected to the outer wall of the sealing plate 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com