Laser welding equipment

A technology of laser welding and laser welding head, which is applied in the direction of laser welding equipment, welding equipment, welding equipment, etc., can solve the problems of limiting the scope of application, the angle of the laser welding head cannot be adjusted, etc., so as to avoid the displacement of the workpiece and expand the scope of application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

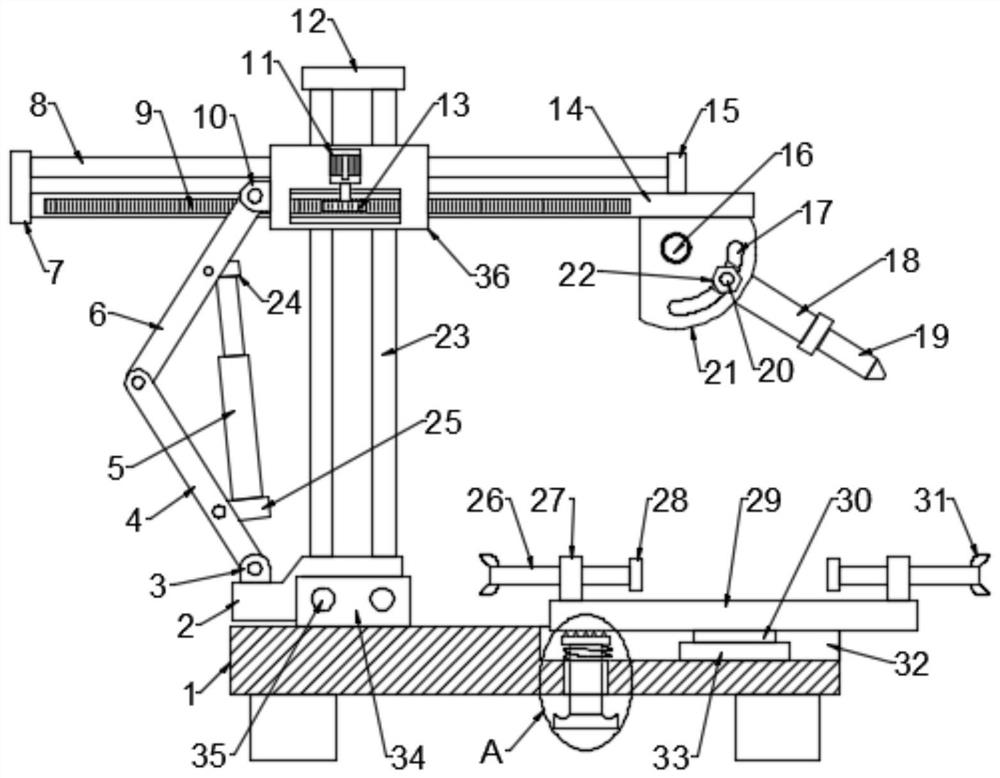

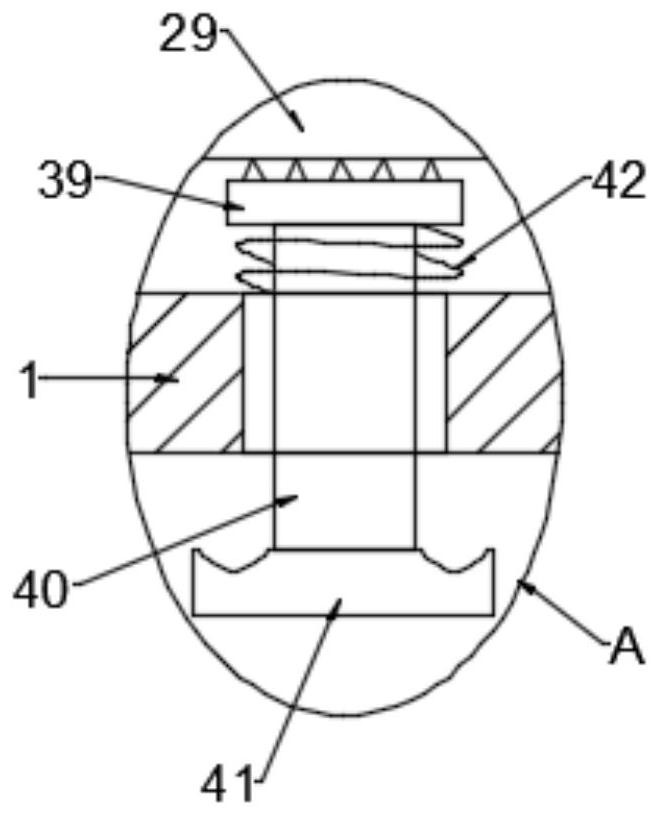

[0029] see Figure 1-3 , in the embodiment of the present invention, a kind of laser welding equipment comprises base plate 1 and laser welding head 19, and the upper side of base plate 1 is provided with turntable 29; There is a bearing seat 33, a groove 32 is provided on the bottom plate 1, and the bearing seat 33 is installed in the groove 32;

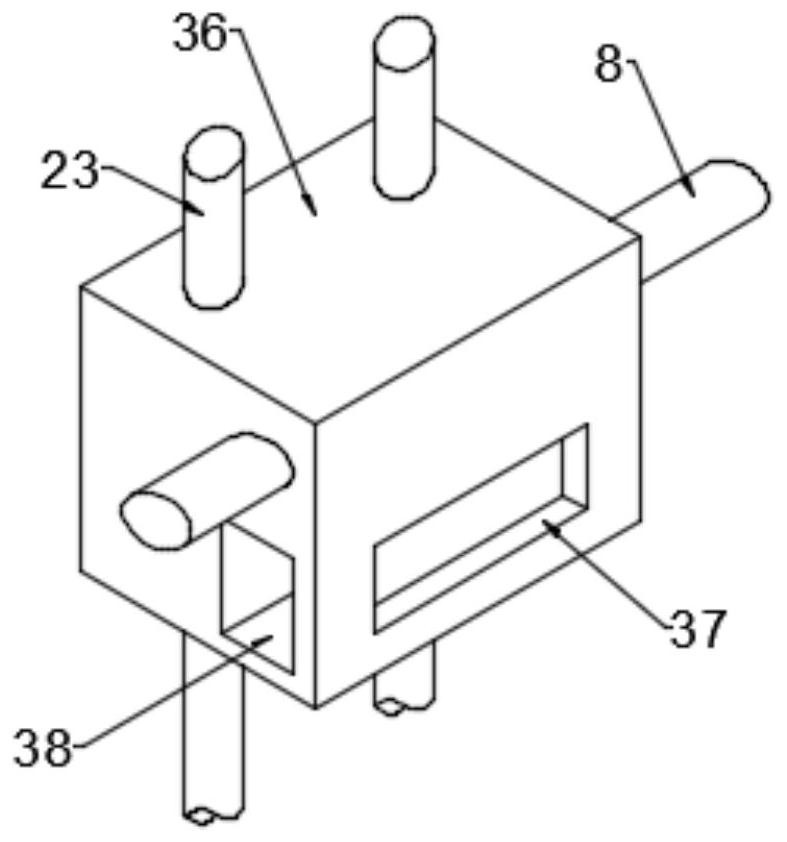

[0030] Two vertical plates 34 are fixed on the base plate 1, a third guide rod 35 is connected between the two vertical plates 34, a mobile base 2 is slidably arranged on the third guide rod 35, and a second guide rod is fixed on the mobile base 2. Rod 23, the top of the second guide rod 23 is provided with top plate 12, and the second guide rod 23 is slidably provided with lifting seat 36, and the moving base 2 is provided with the connecting rod assembly that is used to drive lifting seat 36 lifting, and the lifting seat 36 is provided with Passage 38 is arranged, and cross bar 14 is perforated in passage 38, and cross bar 14 is ...

Embodiment 2

[0041] see Figure 4 , in the embodiment of the present invention, a kind of laser welding equipment is different from Embodiment 1 in that a bracket 44 is fixed on the rotating rod 18, and a supplementary light 43 is installed on the support 44; the supplementary light 43 can be used to supplement Light, reduce the impact of insufficient light on welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com