Device for grasping electromagnetic transducer to assist nondestructive testing and trajectory planning method of device

A technology of non-destructive testing and trajectory planning, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as errors, time-consuming and labor-intensive, data errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

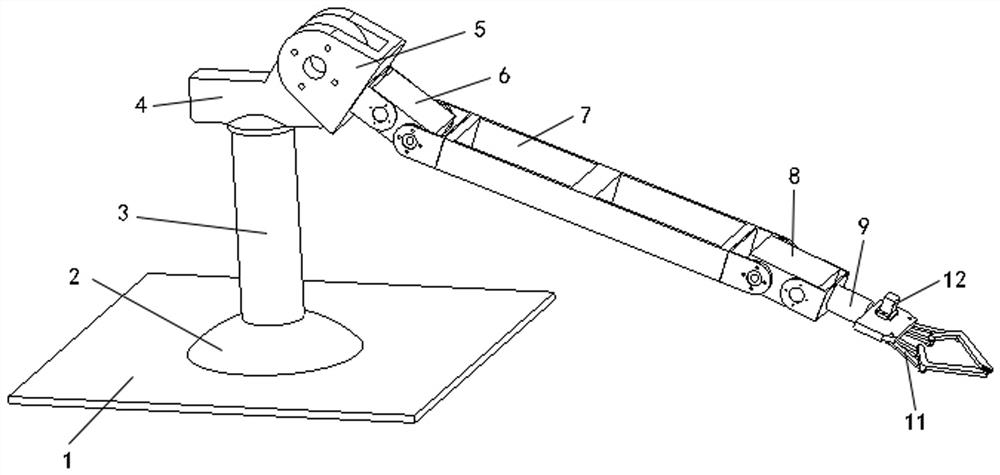

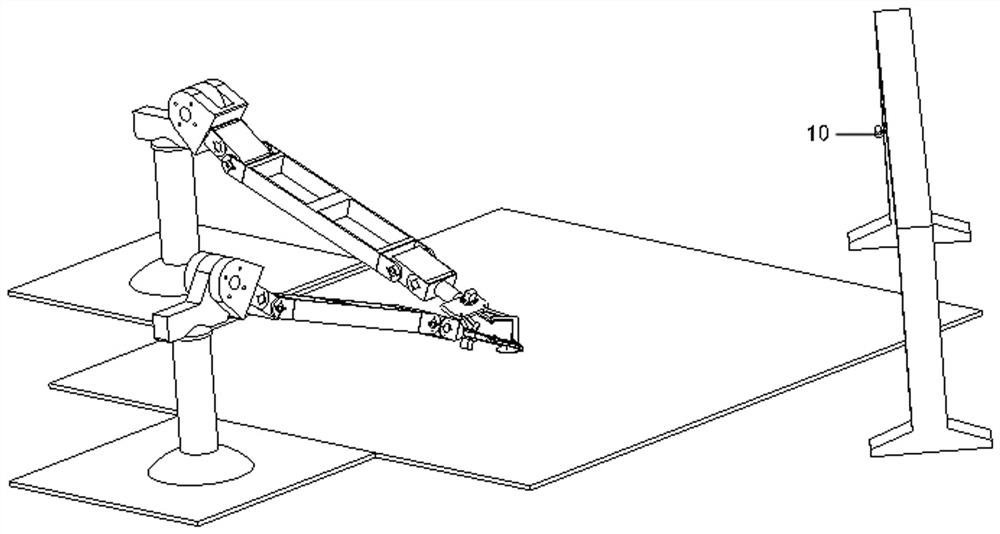

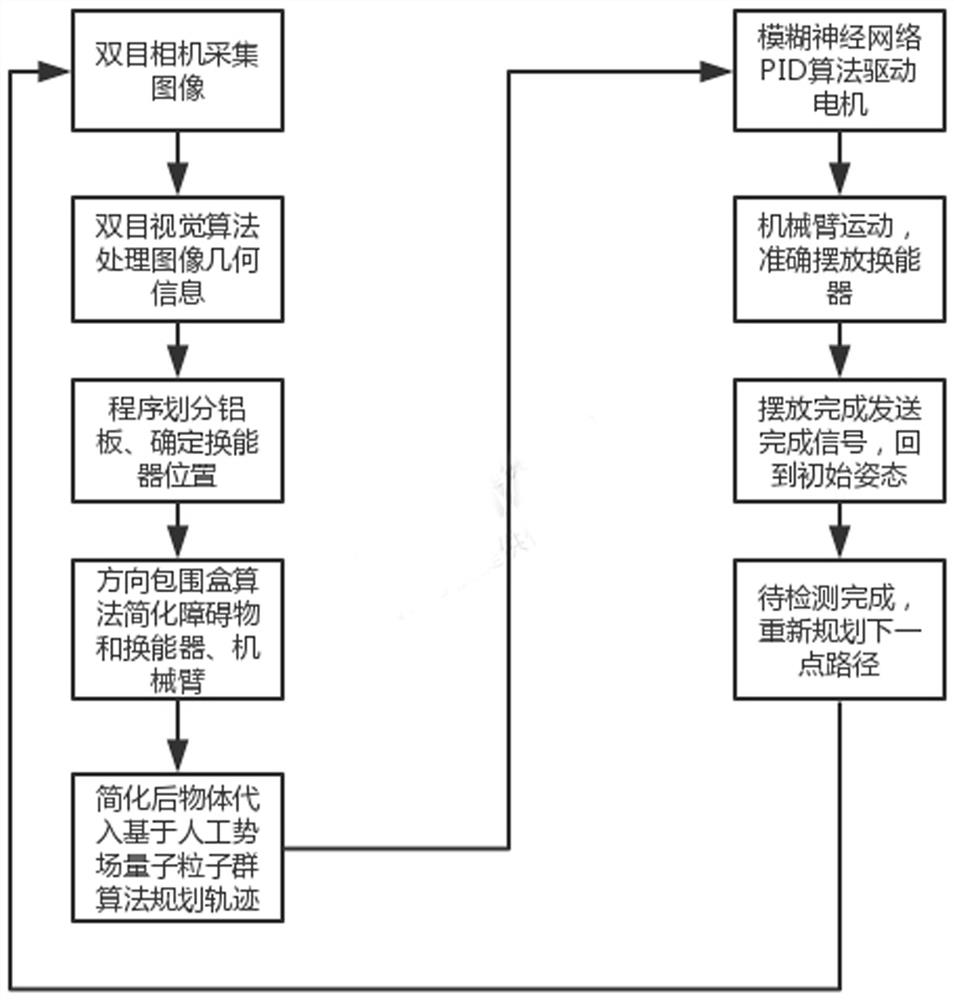

[0061] like figure 1 As shown, a device for grasping electromagnetic transducers to assist non-destructive testing includes two mechanical arms and a binocular camera 10. The two mechanical arms are respectively arranged on the mechanical arm support base 1 around the testing platform, and placed on the testing platform For the metal plate to be detected, the two mechanical arms cooperate with the clamping electromagnetic transducer to move and detect on the metal plate to be detected; the binocular camera 10 is set on the support frame around the detection table, and is used to collect the metal plate to be detected, the electromagnetic transducer Images of energy devices and robotic arms;

[0062] like figure 2 As shown, the mechanical arm includes a first rotating shaft 2, a support column 3, a first mechanical arm 4, a fixing device 5, a first steering gear 6, a second mechanical arm 7, a second steering gear 8, and a second rotating shaft 9. Mechanical claw 11, geared ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com