A cup mouth base mold convenient for assembly and construction

A cup-based, easy-to-assemble technology, applied in infrastructure engineering, construction, etc., can solve problems such as time-consuming, not stable and reliable connection methods, and unsuitable for dismantling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

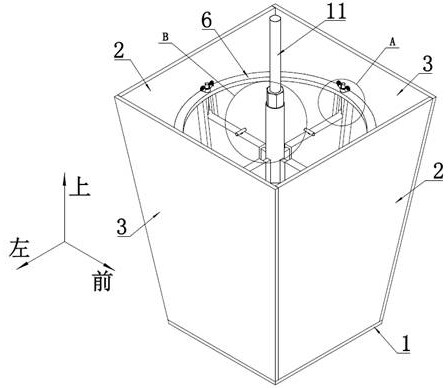

[0040] For the convenience of description, the coordinate system is defined as figure 1 , and the left-right direction is horizontal, the front-back direction is vertical, and the up-down direction is vertical.

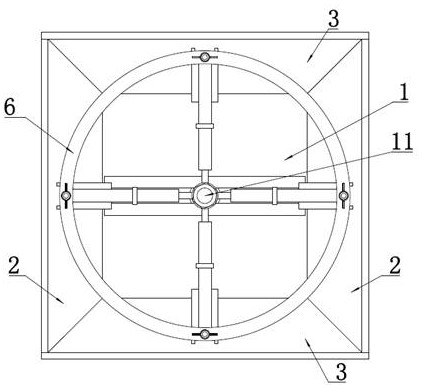

[0041] Such as figure 1 As shown, a cup base mold convenient for assembly and construction includes a bottom template 1 and side templates, and the bottom template 1 and the side templates together form a quadrangular pyramid structure with a large upper end and a small lower end. base model. Described side formwork comprises first side formwork 2 and second side formwork 3, and quantity is two, as figure 2 As shown, wherein the first side formwork 2 is arranged on the front and rear sides of the bottom formwork 1, the second side formwork 3 is arranged on the left and right sides of the bottom formwork 1, and the first side The left side and the right side of the template 2 are respectively pressed against the inner side of the second side template 3 (with the op...

Embodiment 2

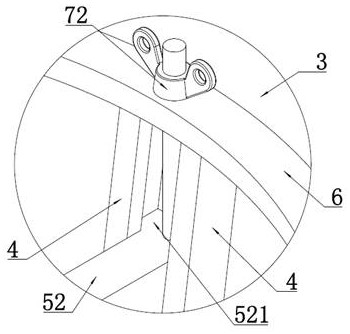

[0059] The pressing plate 6 is a circular plate, and the lower side of the circular plate abuts against the upper end surface of the basic side form. A through hole for accommodating the upright post 511 is provided at the center of the circular plate, and the upper end of the upright post 511 passes through the through hole and extends above the pressing plate 6 . External threads are provided on the outer cylindrical surface of the column 511 , and a second compression nut 72 is provided on the column 511 above the compression plate 6 . All the other structures are the same as in Embodiment 1.

Embodiment 3

[0061] A support plate is arranged below the first chute on the inner side of the first side formwork 2 and the second side formwork 3, and a pressing plate is arranged above the support plate in the basic side form. plate 6, and the lower side of the pressing plate 6 abuts against the upper side of the supporting plate. The clamping bolts are arranged under the top plate 52 on the clamping plate 6, and the clamping bolts are threadedly connected with the clamping plate 6, and the ends of the clamping bolts are tightened. on the underside of the top plate 52 . All the other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com