Small-space parallel inclined entering shrinking type vegetable pot seedling transplantation tail end executor

An end-effector, small-space technology, applied in transplanting machinery, applications, agriculture, etc., can solve the problems of side-by-side pot seedling transplanting that is not suitable for small spaces, relatively high substrate moisture content, and low success rate. The effect of automated large-scale production, improved grasping success rate, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Further description will be given below in conjunction with the embodiments shown in the accompanying drawings.

[0025] For the convenience of description, the figure 2 Above is up and below is down.

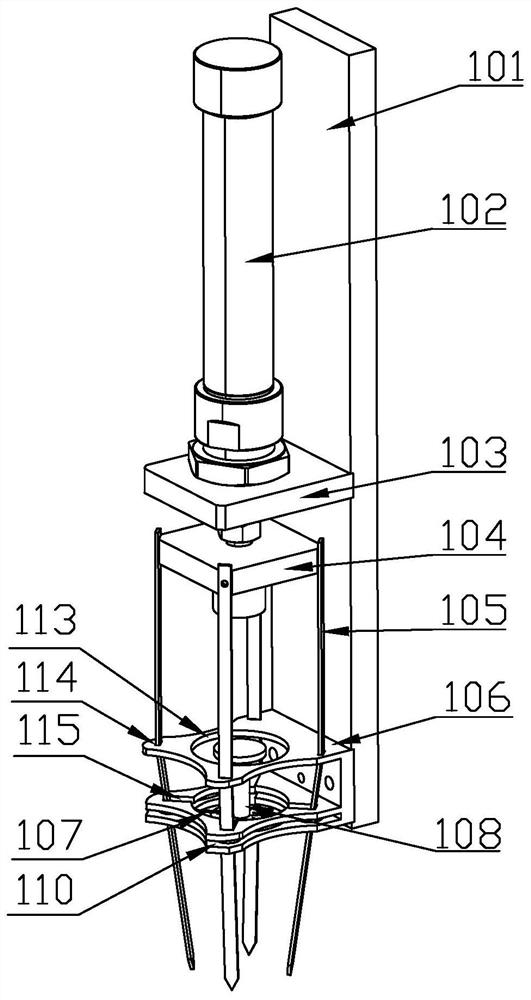

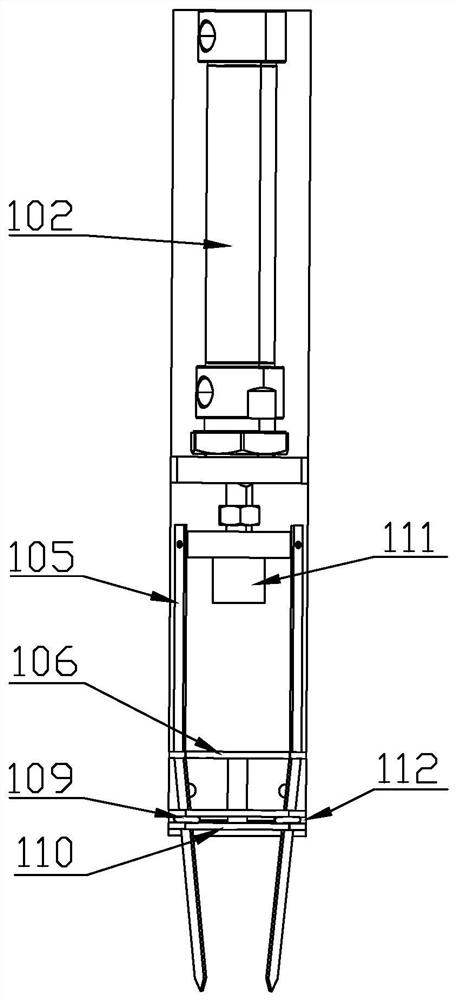

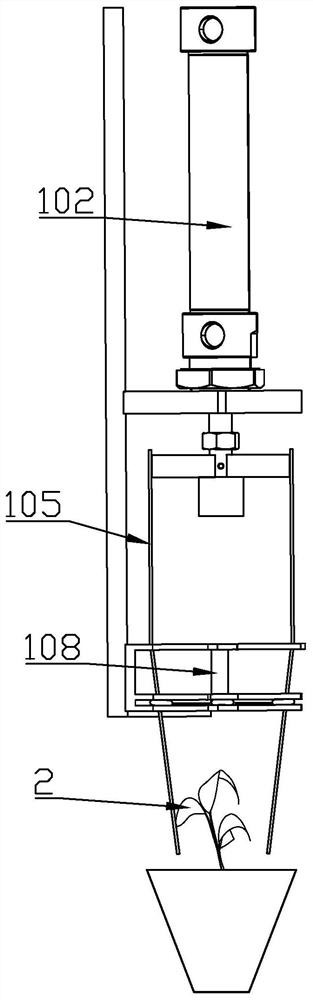

[0026] Such as figure 1 , figure 2 The shown small space parallel oblique retractable leaf vegetable pot seedling transplanting end effector includes a support base 101, a cylinder 102, a claw needle fixing plate 104, a guide plate 106, a partition 110, several claw needles 105, and several rings 109. Several steel wire ropes 107 and retraction blocks 108 (the number of claw needles, rings and steel wire ropes in this embodiment is four and corresponds one by one).

[0027] Described cylinder is vertically installed on the support base of 42.5mm wide by cylinder fixing plate 103. The claw needle fixing plate, guide plate and partition are arranged horizontally at intervals from top to bottom; wherein, the claw needle fixing plate is fixed at the end of the cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com