Wire clamping device of hot-line work robot and operation method thereof

A technology for live work and wire clamps, applied in the directions of circuit/collector parts, circuits, electrical components, etc., can solve the problems of overload damage to the robot arm, the operation cannot be carried out normally, and the risk of failure to catch the wire is high, so as to overcome the load Insufficient, improve the success rate of grabbing, improve the effect of working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings, and the technical solution of the present invention will be explained more clearly and completely.

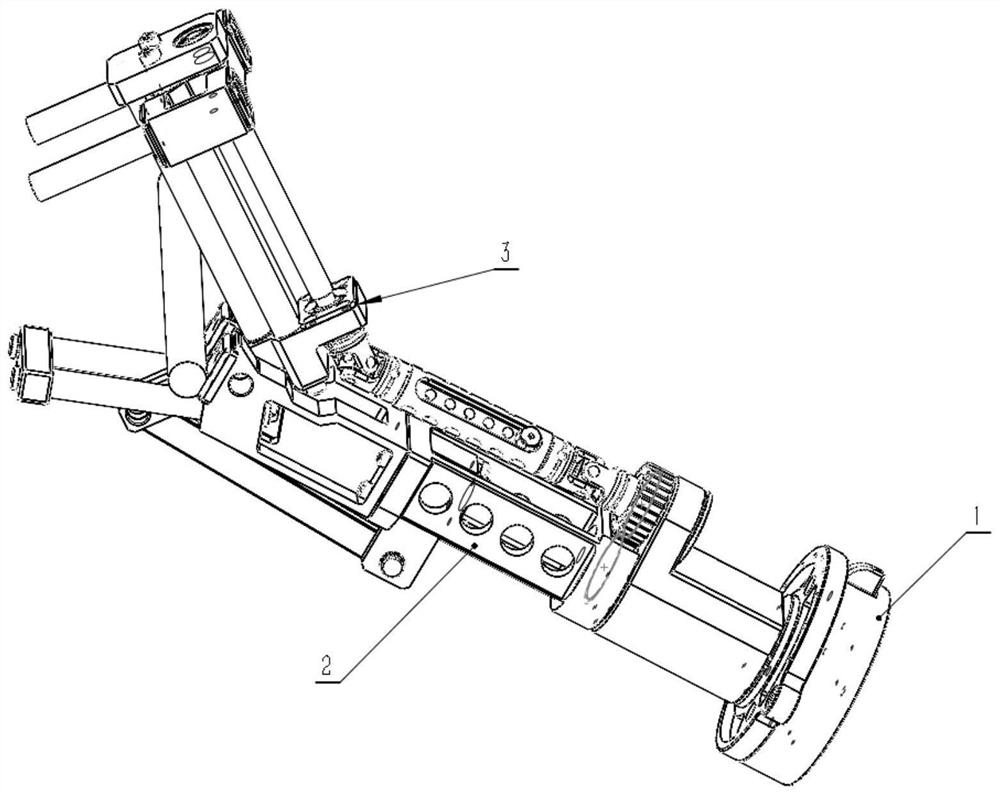

[0026] Such as figure 1 Shown is a new type of tensioner for a live working robot, which includes a docking assembly 1 , a fixed jaw assembly 2 , and a movable jaw assembly 3 .

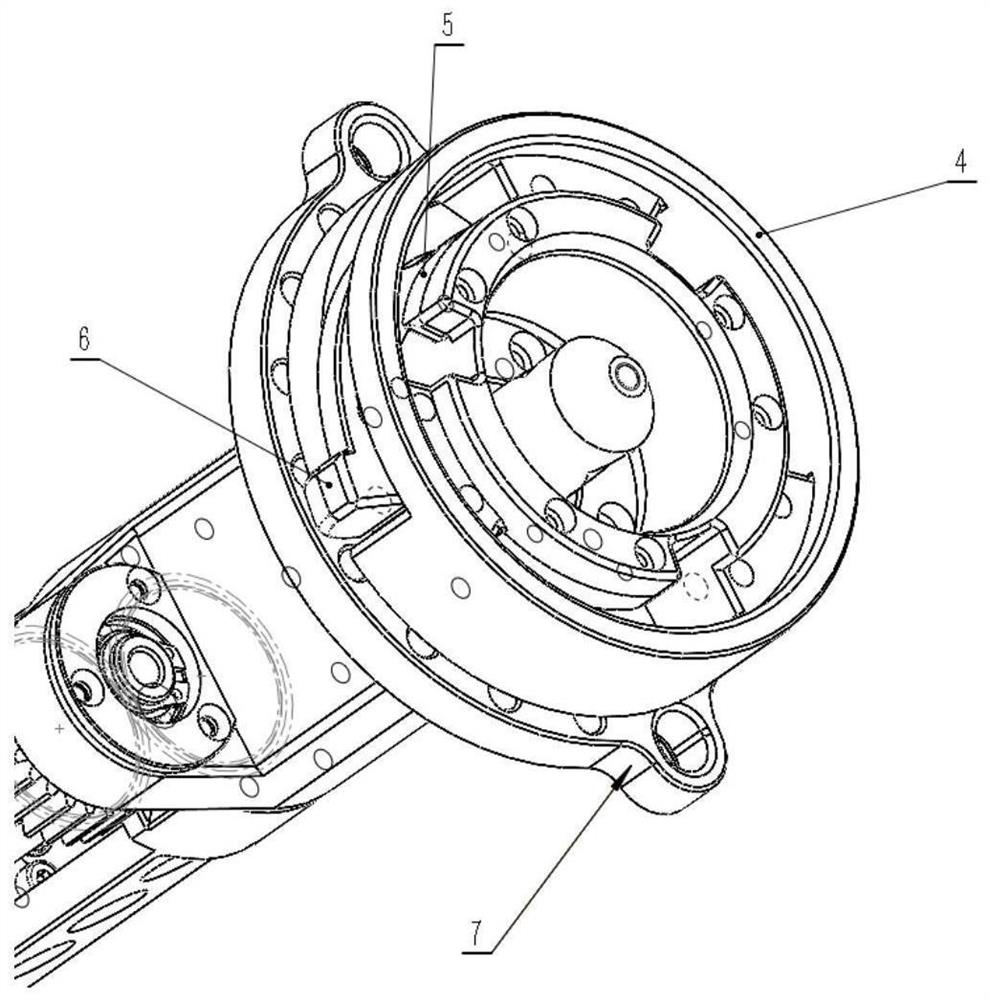

[0027] Such as figure 2 As shown, the docking assembly 1 includes a tool tray 4, an inclined plane block 5, a locking lever 6, and a guide positioning plate 7, wherein three inclined plane blocks 5 are connected to the tool tray 4 by screws, and the locking lever 6 is connected to the tool tray 4 A spring is compressed between them, connected by a straight pin, and the guiding positioning disc 7 and the tool disc 4 are fixed by screws.

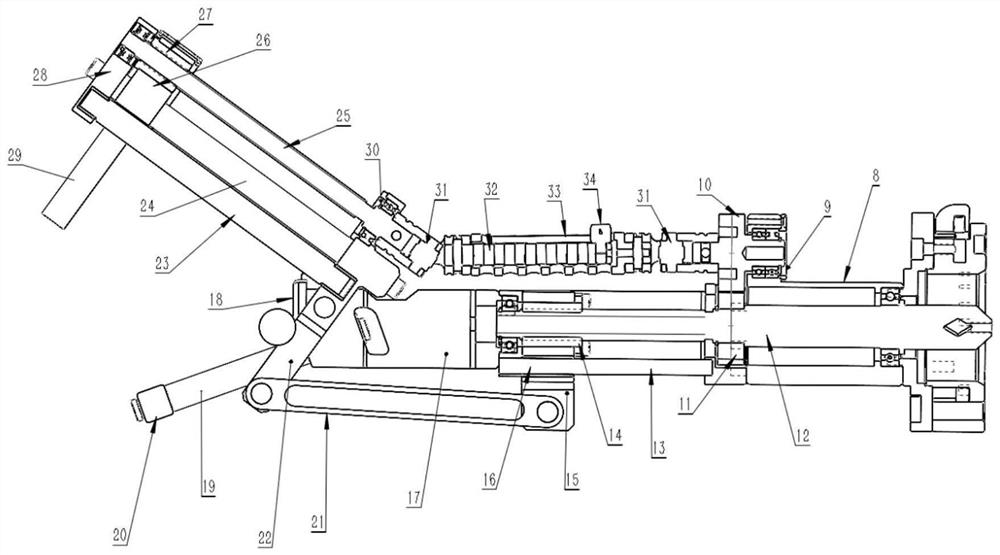

[0028] Such as image 3 As shown, the fixed jaw assembly 2 includes a gear base 8, a thread clamping screw rod 12, a thread clamping base 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com