Building brick quality inspection device and method

A detection device, a brick-and-mortar technology, applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve the problems of low detection accuracy and inconvenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

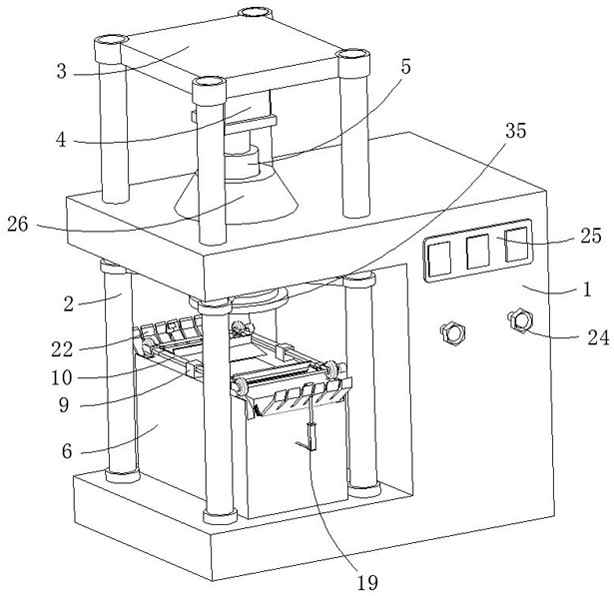

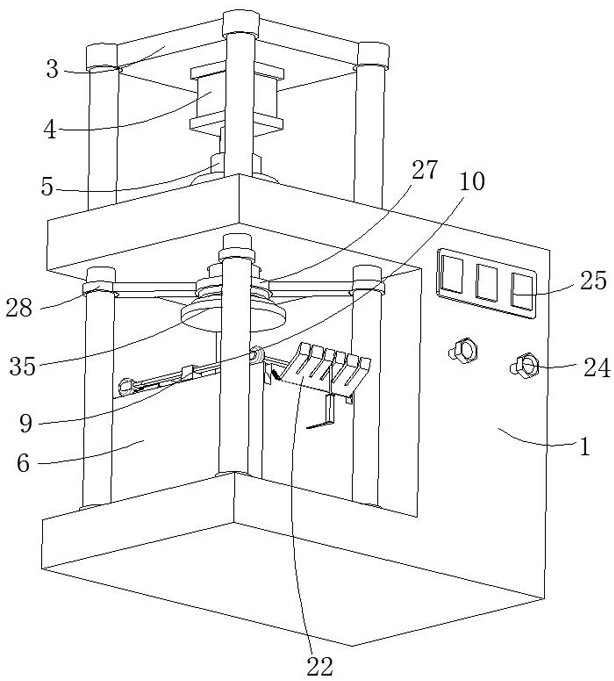

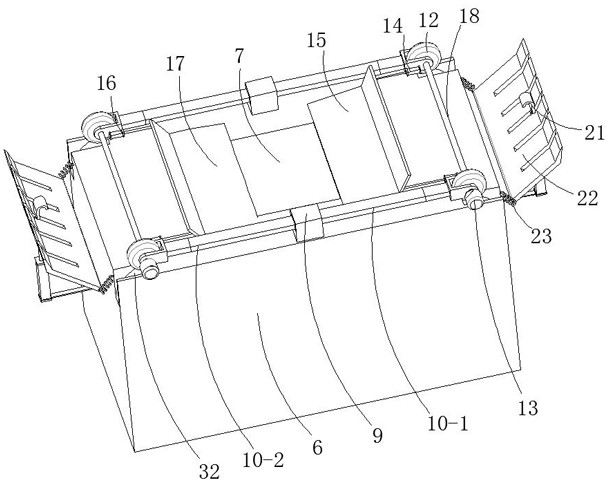

[0046] refer to Figure 1-5 , Figure 9 , a kind of construction brick quality detection device and detection method thereof, comprises workbench 1, and workbench 1 is specifically concave shape, and workbench 1 is provided with four sliding bars 2 that run through distribution, and the top of slide bar 2 is fixedly provided with mounting plate 3. The bottom of the mounting plate 3 is fixed with a lower pressure cylinder 4, and the piston rod at the output end of the lower pressure cylinder 4 is fixed with a lower pressure rod 5. Depression bar 5; The concave bottom wall of workbench 1 is fixedly provided with detection table 6, and the top center position of detection table 6 is provided with installation groove, is provided with object table 7 in the installation groove, and between object table 7 and the bottom wall of installation groove A pressure sensor 8 is arranged between them, and symmetrically distributed limit fixing blocks 9 are fixed on both sides of the top cen...

Embodiment 2

[0051] refer to Figure 6 , Figure 8 , Figure 10 , Figure 11 , Figure 12 , is basically the same as Embodiment 1, furthermore, the limit fixing block 9 is provided with sliding holes matching the first connecting rod 10-1 and the second connecting rod 10-2, and the size of the mounting block 11 is larger than the sliding hole. The size of the hole, so that the mounting block 11 is limited to one side of the limit fixing block 9; the first connecting rod 10-1 and the second connecting rod 10-2 are connected by an adapter shaft 33, and on the adapter shaft 33 A power spring 34 is sleeved, and the two ends of the power spring 34 are fixedly connected with the first connecting rod 10-1 and the second connecting rod 10-2 respectively, and the presence of the power spring 34 is convenient for the first connecting rod 10-1 and the second connecting rod After the two connecting rods 10-2 rotate relative to each other, the reset between the two is realized. The existence of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com