Stuffing sand removing method for casting start of continuous casting steel ladle

A technology for draining sand and continuous casting steel, applied in the field of continuous casting in the metallurgical industry, can solve the problems of difficult layout, easy freezing of molten steel, increase of fault points, etc., and achieve a good effect of elimination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

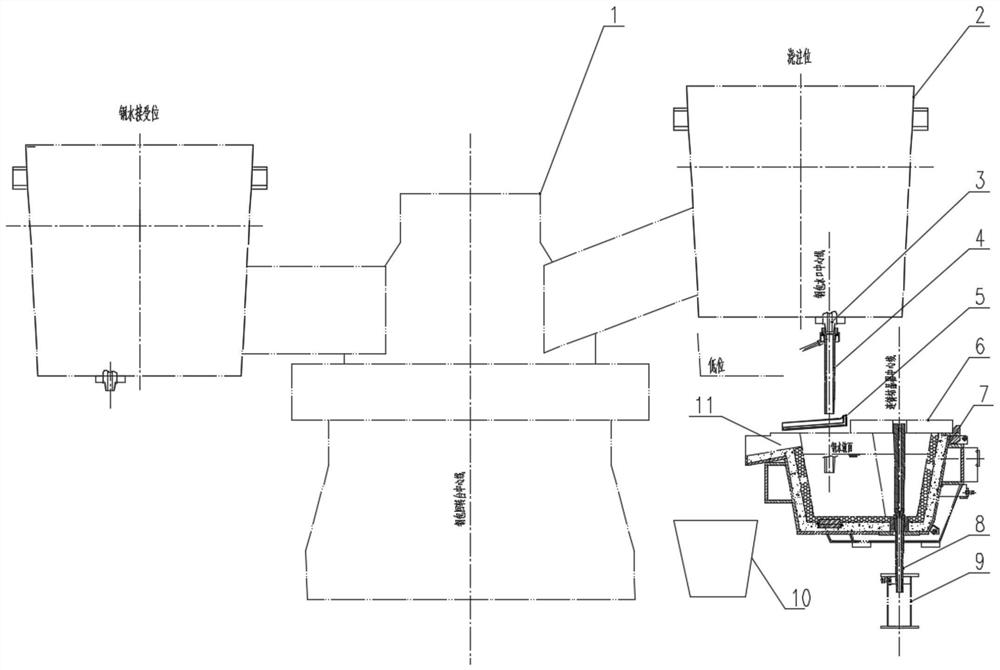

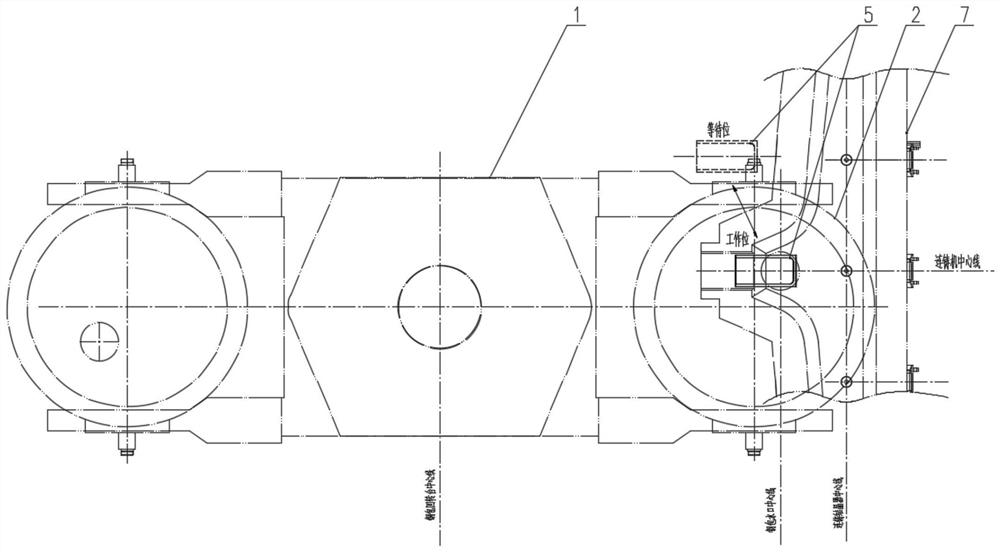

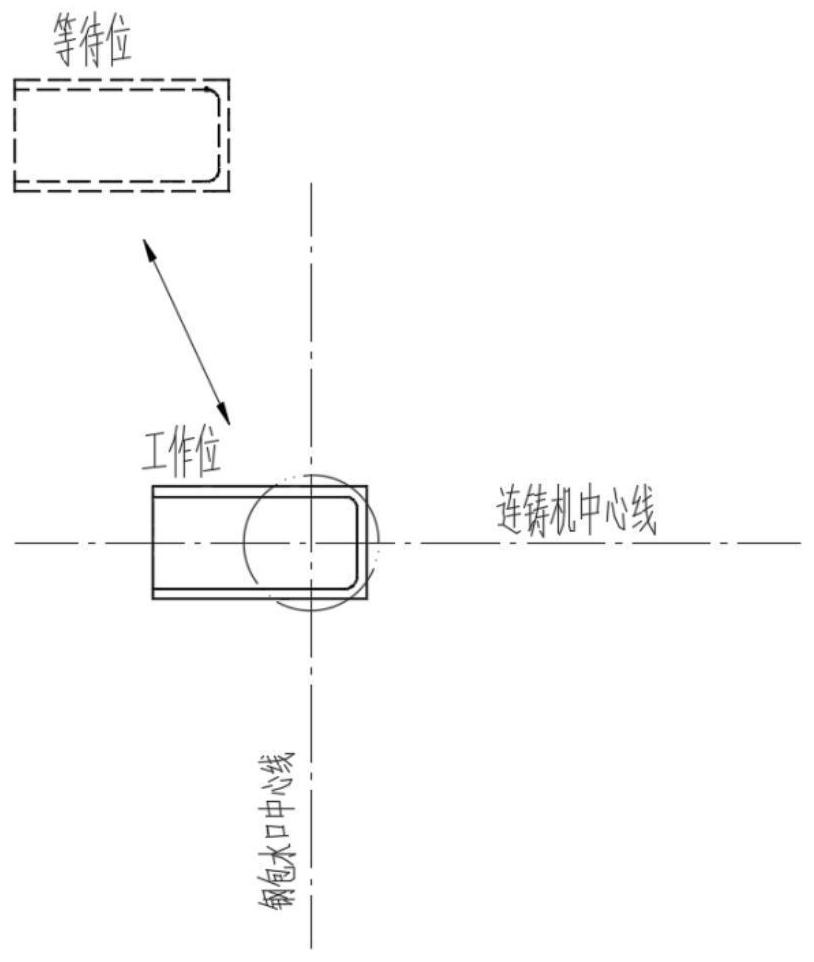

[0026] Such as Figure 1 to Figure 3 As shown, in the continuous casting process of a continuous casting machine, a ladle of molten steel needs to be replaced after the pouring of the next ladle of molten steel. The replacement of the continuous casting ladle 2 is usually realized through the ladle turret 1, which can rotate 360°. The ladle turret 1 is provided with two slewing arms that can be raised and lowered for receiving the continuous casting ladle 2 . At the end of the pouring of the last ladle of molten steel, the next ladle of molten steel to be replaced is hoisted to the rotary arm at the receiving position of molten steel, and the preparations for the sliding nozzle 3 of the ladle are completed (such as installation of oil cylinders, gas pipelines, etc.), continuous casting The acceptance of ladle 2 can be carried out when the rotary arm is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com