Large automatic feeding machine

An automatic feeding, large-scale technology, applied in the field of large-scale automatic feeding machines, can solve the problems of plastic particles not completely melted, affecting the quality of extrusion granulation, difficult processing and transportation, etc., to ensure smooth and stable, prevent clogging, ensure The effect of feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

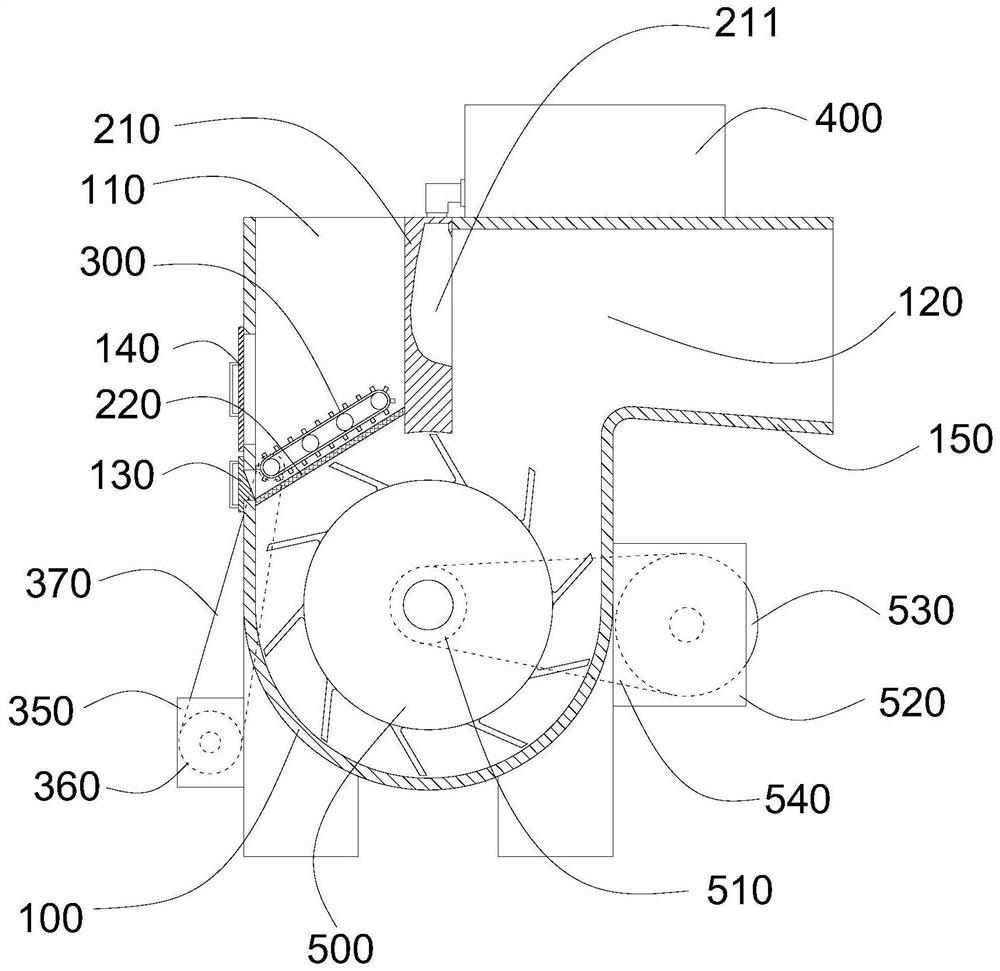

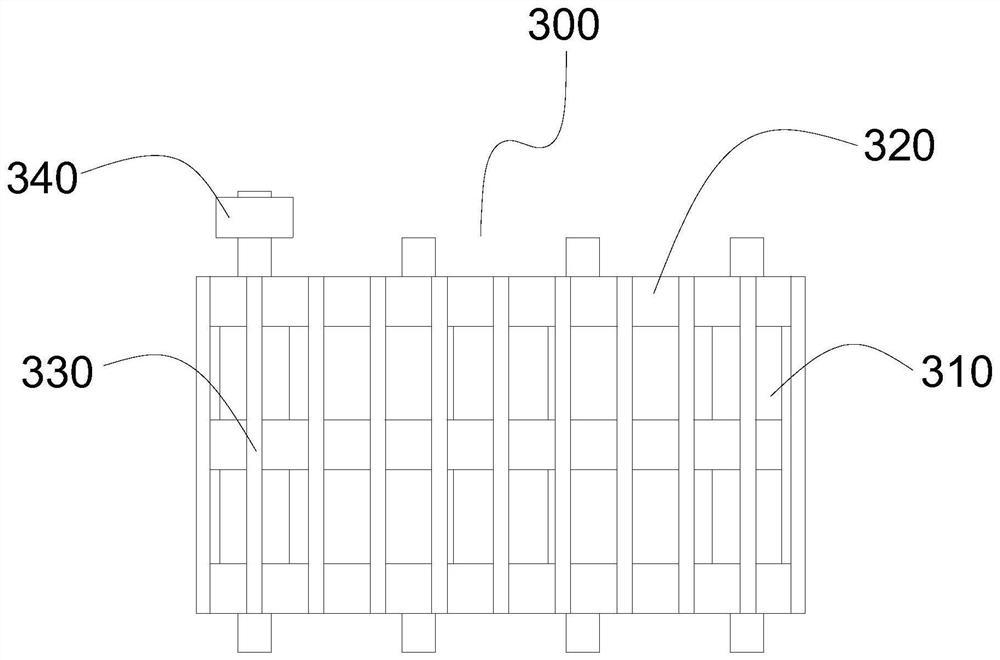

[0019] see figure 1 , a large automatic feeder provided in a specific embodiment of the present invention, which includes a box body 100, a top side of the box body 100 is provided with a feeding port 110, and the side of the box body 100 away from the feeding port 110 A discharge port 120 is provided at the top of the wall; a first partition 210 and a second partition 220 are fixed inside the box body 100, the first partition 210 is vertically arranged, and the top end is held against the feeding port 110 is close to the side of the discharge port 120, the second partition 220 is obliquely arranged at the bottom end of the first partition 210, and the second partition 220 faces a side far away from the discharge port 120. The side is inclined downward, and the end is against the side wall of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com