Omnidirectional mobile equipment

An omnidirectional movement and equipment technology, applied in the direction of motor vehicles, using re-radiation, elastic suspension, etc., can solve problems such as mechanical vibration, poor adaptability to terrain fluctuations, and inability to fully consider the structural requirements for installing LiDAR lidar, and achieve enhanced Adaptability, the effect of reducing mechanical vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

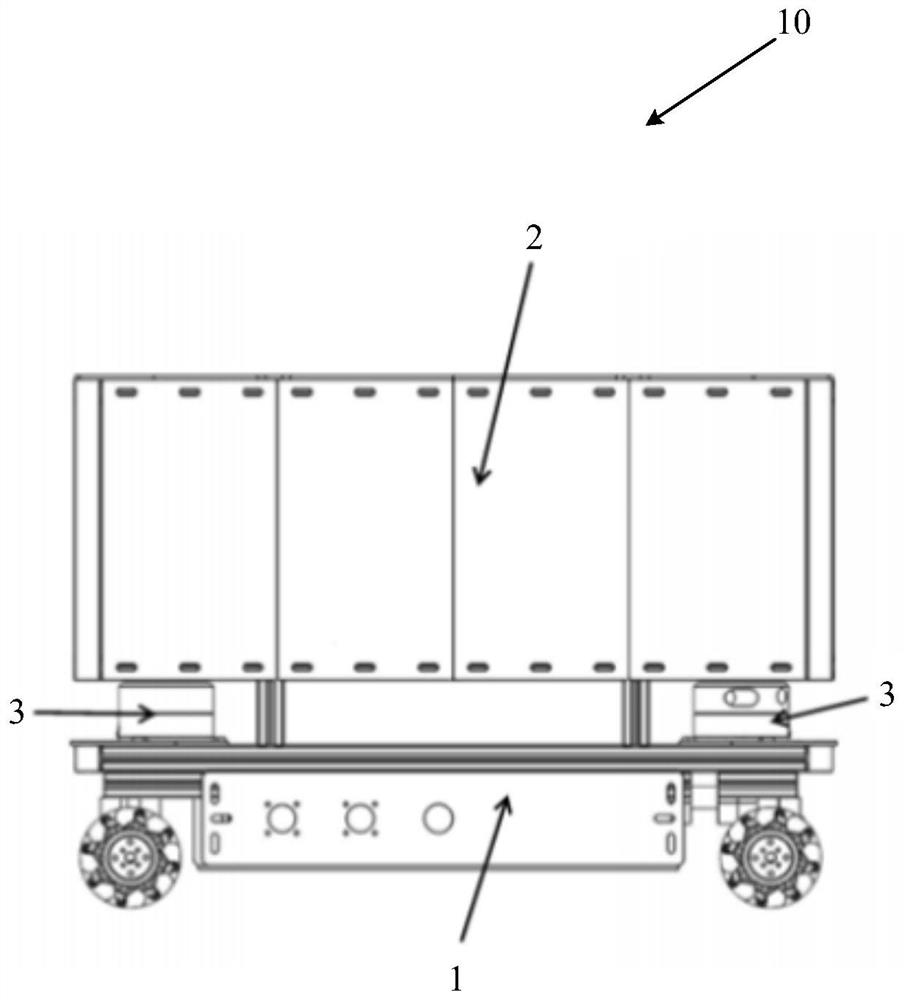

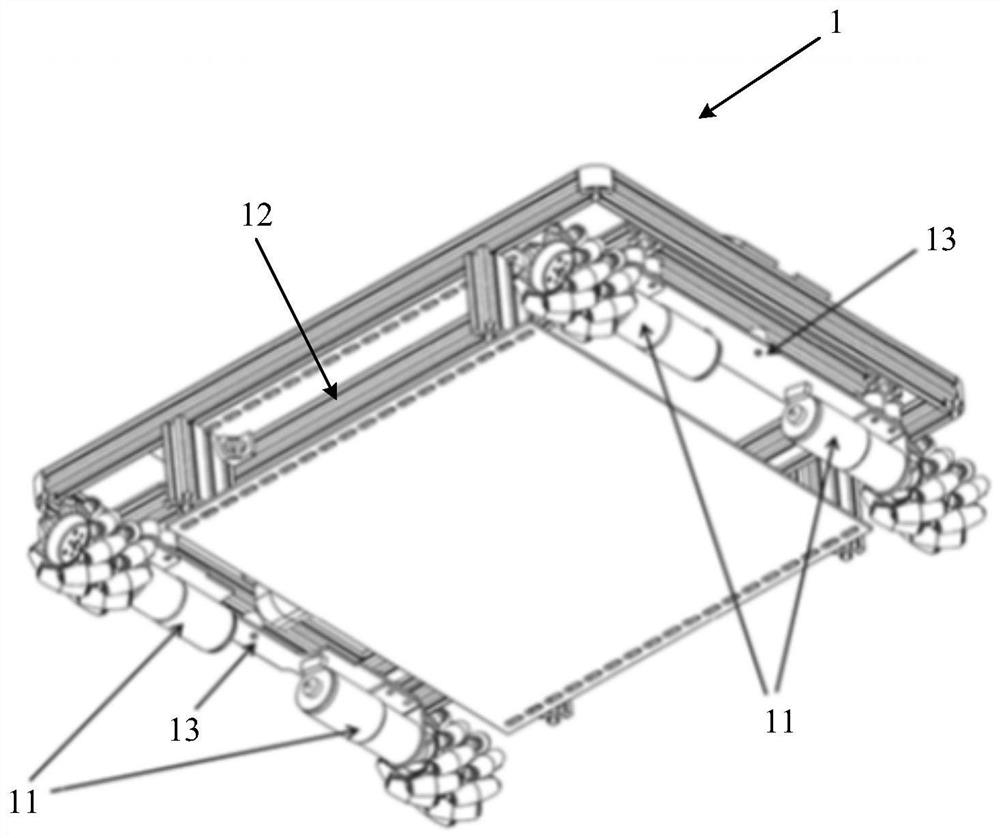

[0037] This embodiment provides an omnidirectional mobile device, including:

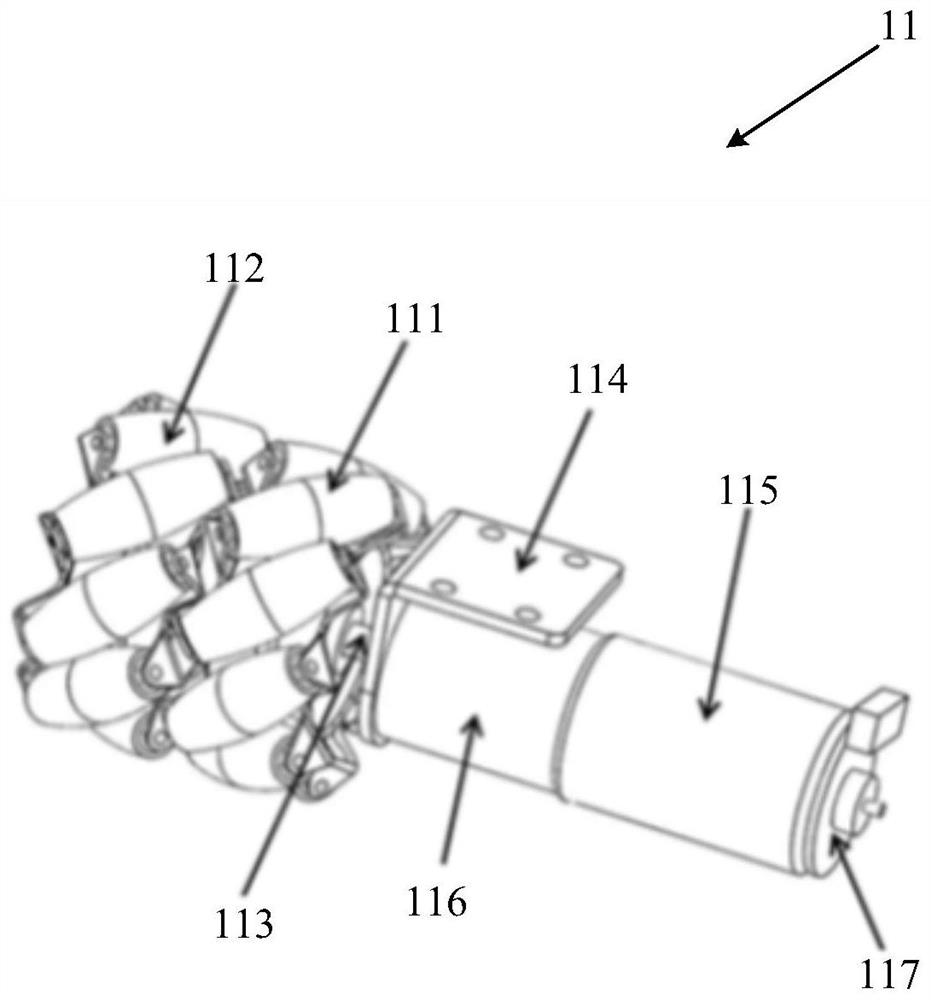

[0038] The running system includes 2N sets of mecanum wheel mechanisms, a body frame and an elastic suspension mechanism; the 2N sets of mecanum wheel mechanisms are symmetrically installed on the body frame through elastic suspension mechanisms, and N is greater than or equal to 2;

[0039] Wherein, when the 2N sets of Mecanum wheel mechanisms are running continuously, the elastic suspension mechanism allows the relative movement of the 2N sets of Mecanum wheel mechanisms on the given mechanical degrees of freedom of the elastic suspension mechanism, so as to absorb the Vibration generated during the operation of the mecanum wheel mechanism;

[0040] The task load cabin is arranged on the traveling system, and a LiDAR laser radar is installed in the cabin of the task load cabin, and the guide rail-free movement of the LiDAR laser radar is driven by the travel system.

[0041] The omnidirectional m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com