Manually-opened-and-closed gate valve

A plug-in valve and valve frame technology, which is applied in sliding valves, valve details, valve devices, etc., can solve the problems of affecting flow, high labor intensity, and inability to accurately control the size of the discharge opening, and achieve easy control and low operation intensity. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

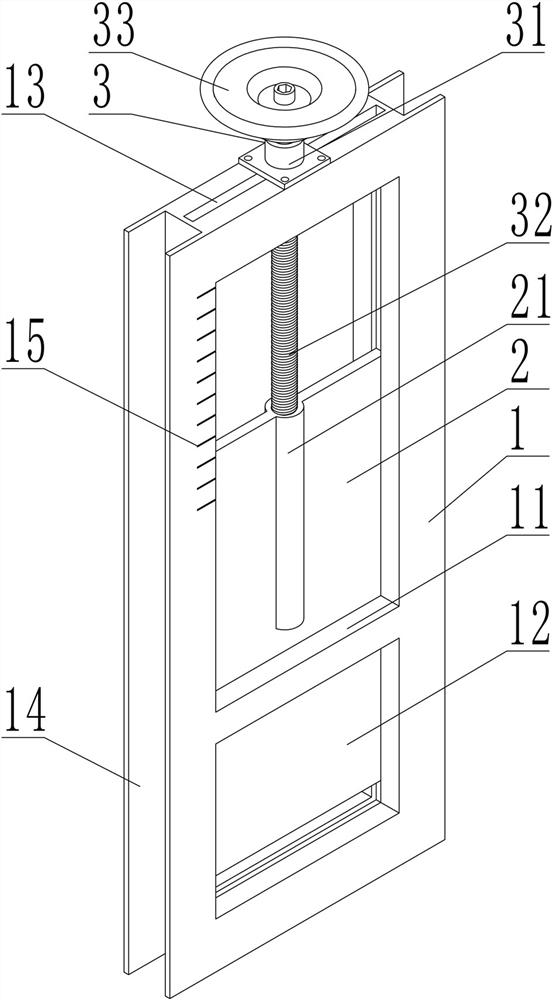

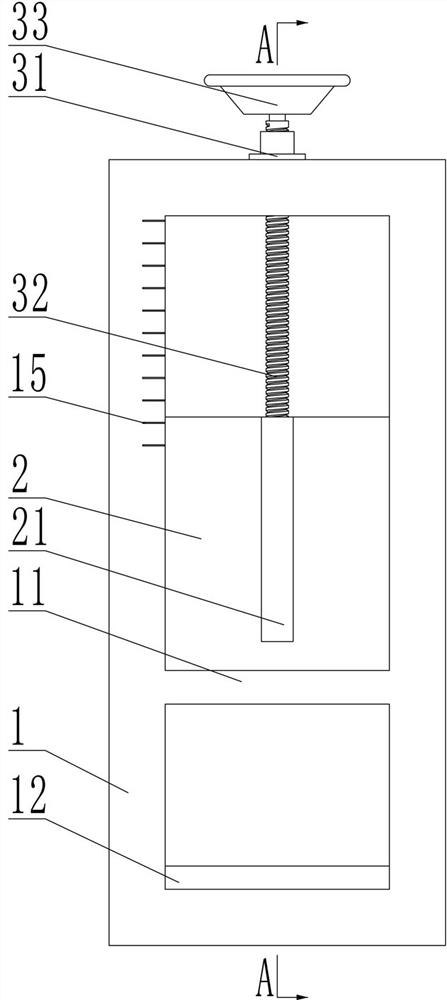

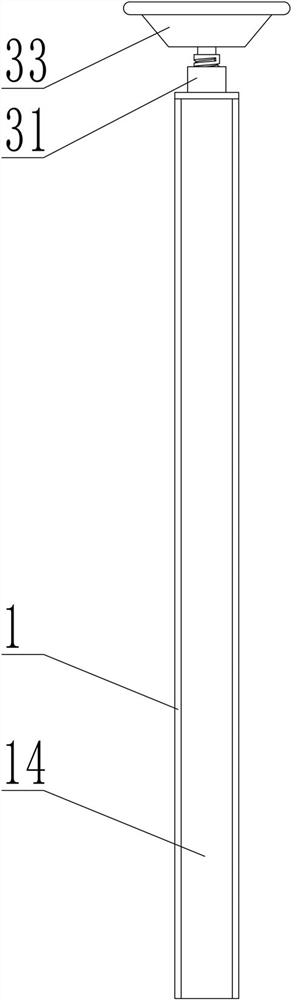

[0031] Such as Figure 1~Figure 6 Among them, a flapper valve with manual opening and closing, which includes a valve frame 1, a gate plate 2 and a propulsion mechanism 3; Connection, the screw rod 32 is screwed with the screw rod seat 31 and the gate plate 2, and the screw rod 32 rotates to push the gate plate 2 to telescopically open and close the valve port 12 on the valve frame 1. The structure is simple, by setting the gate plate 2 in the valve frame 1, the propulsion mechanism 3 and the valve frame 1 are fixed and screwed with the gate plate 2, and the screw 32 of the propulsion mechanism 3 is rotated to push the gate plate 2 to slide to open and close the valve on the valve frame 1 Port 12 controls the opening and closing of the valve port 12 through the top of the gate plate 2 and the scale 15 on the valve frame 1. The opening and closing are precise, easy to control the flow rate, and the operation intensity is low, and the operation is simple and convenient.

[0032...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com