Control method of heat dissipation system of high-capacity generator set

A technology for generating sets and cooling systems, applied in electric components, engine components, machines/engines, etc., can solve the problems of complex structure of the cooling system, uneven temperature, large ventilation loss, etc., to meet the cooling effect, reduce ventilation, The effect of reducing the power consumption of the unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

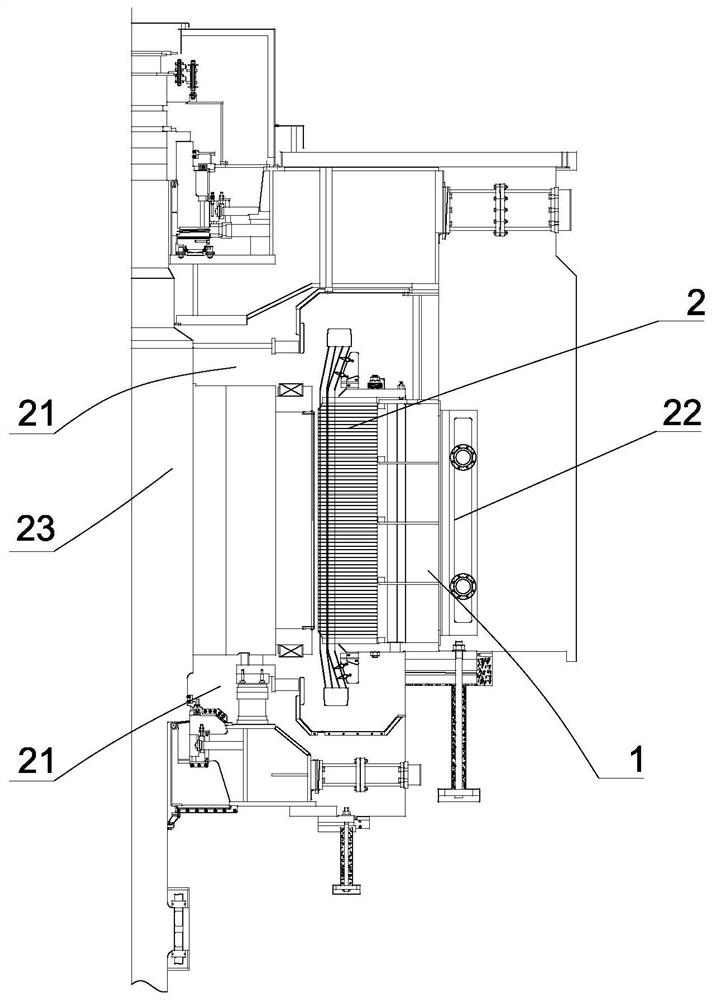

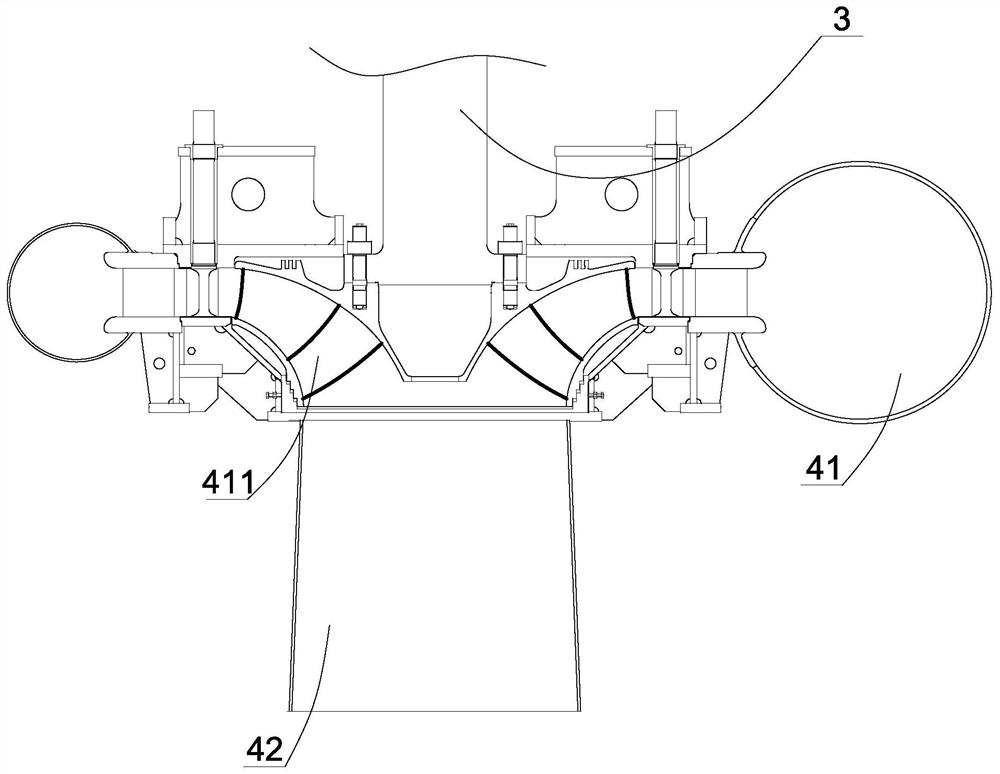

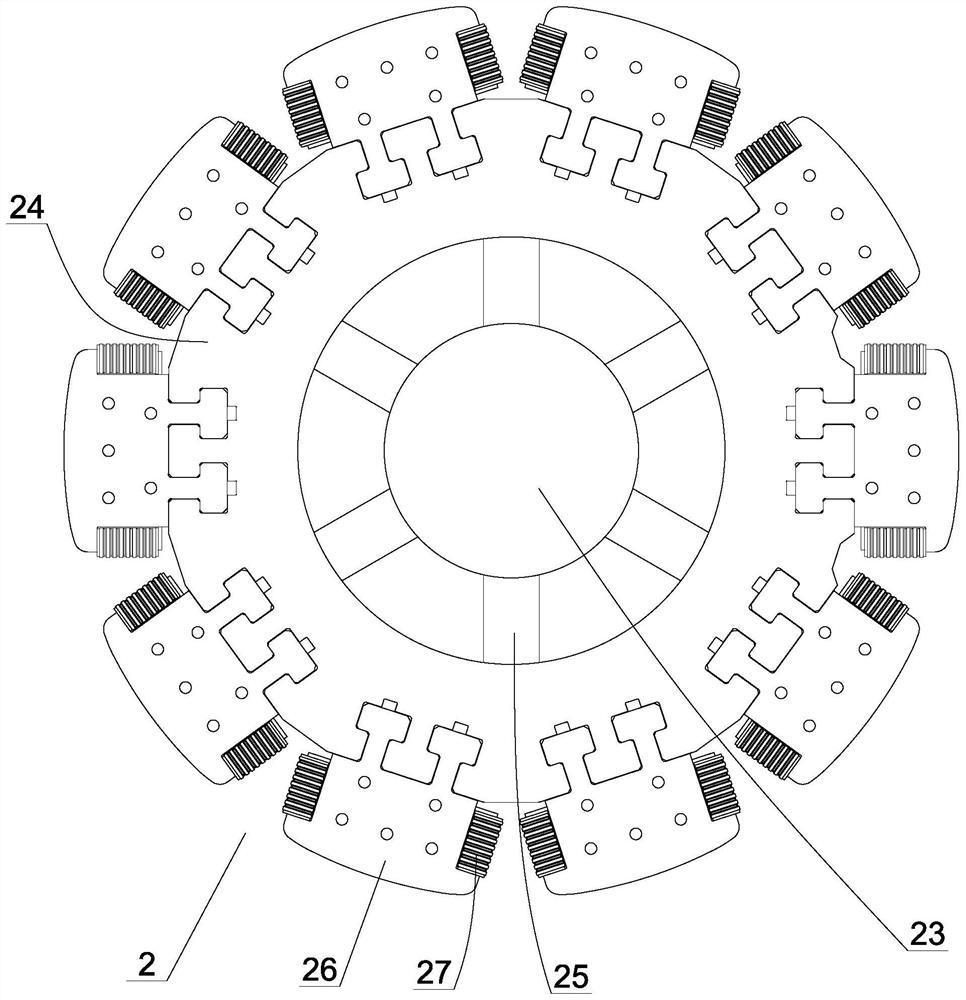

[0042] A control method for the heat dissipation system of a large-capacity generating set, such as figure 1 As shown, the generator set includes a stator 1, a rotor 2 rotatably arranged in the stator, and an air supply device (not shown in the figure) for driving cooling air to dissipate heat for the rotor and the stator, and the rotor is driven with the runner connect. The runner is rotatably set in the volute of the machine pit, such as figure 2 As shown, the runner includes a shaft body 3 connected with the rotor transmission, blades arranged on the shaft body, the volute is provided with a water inlet side and a water outlet side, the water inlet side is provided with a water inlet pipe 41, and the water outlet side of the volute is provided with a water outlet pipe 42. One end of the water inlet pipe is the water spray port 411 facing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com