protective clothing for medical use

A technology for protective clothing and medical use, applied in the field of protective clothing, can solve the problems of poor airtight performance and poor air permeability of protective clothing, and achieve the effects of preventing stuffiness, simple structure, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

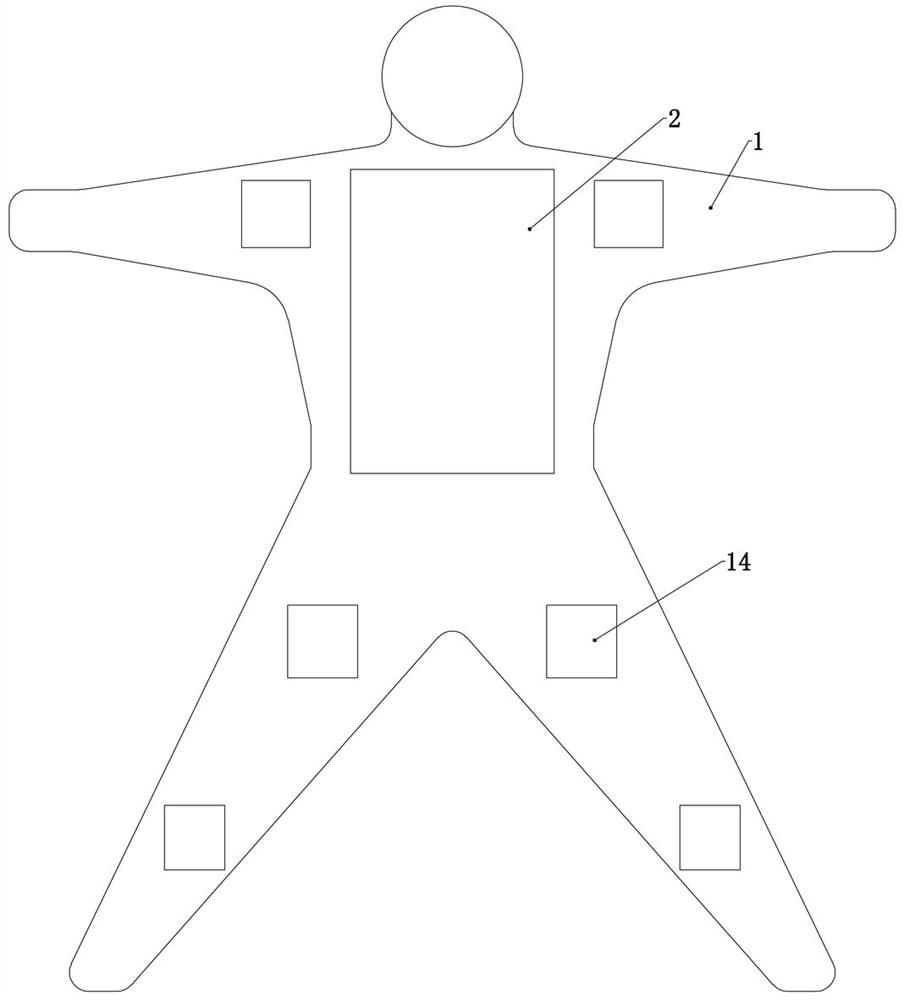

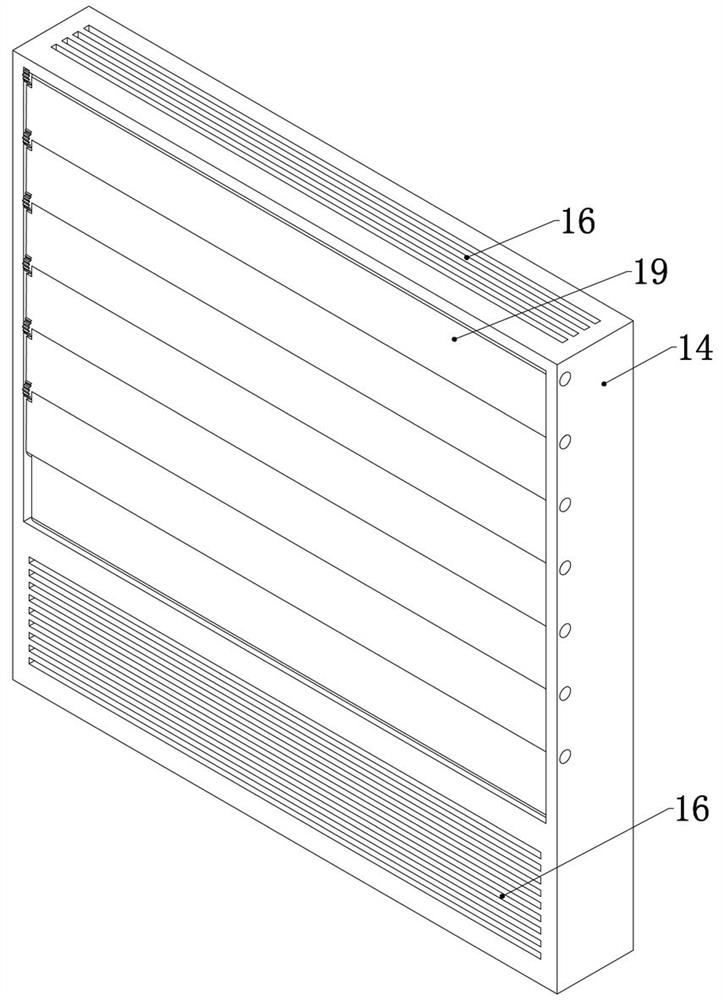

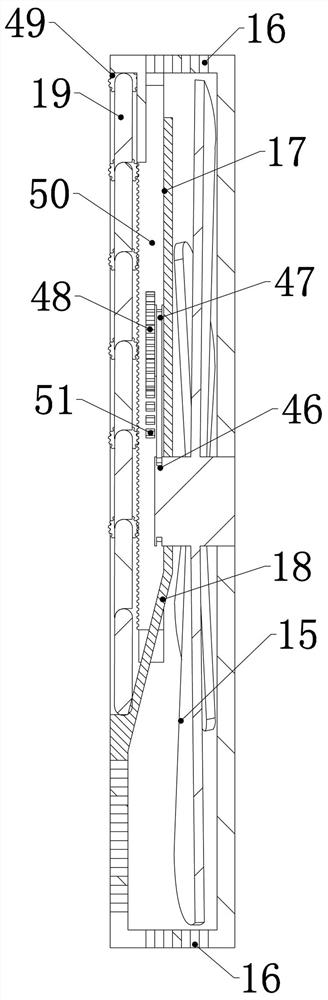

[0040]Embodiment 1, the present invention is a kind of protective clothing for medical use, including protective clothing 1, described protective clothing 1 is a common protective clothing 1, which can provide a fixed foundation for subsequent structures, and the protective clothing 1 adopted in the present invention is preferably a zipper The protective clothing 1 on the chest is convenient for subsequent arrangement on the back of the protective clothing 1 and does not interfere with the normal putting on and taking off of the protective clothing 1. It is characterized in that the back of the protective clothing 1 is detachably connected with a box body 2, and its thickness is about 10 centimeters, about 60 centimeters in height, the box body 2 is provided with an upper warehouse 3, a middle warehouse 4, and a lower warehouse 5. The three warehouses are separated by two partitions fixedly connected to the inside of the box body 2. Bins are adjacent in turn, refer to Figure ...

Embodiment 2

[0043] Embodiment 2, on the basis of Embodiment 1, the middle chamber 4 is fixedly connected with a cooling chamber 20, and the cooling chamber 20 is used to store a solid cooling agent, which can be dry ice, ice or other common fixed cooling The cooling chamber 20 is connected to the middle chamber 4 and a switch of the cooling chamber 20 is arranged at the connecting place. After the switch of the cooling chamber 20 is opened, the cooling chamber 20 is opened, and the solid cooling agent in the cooling chamber 20 can cool the air passing through the middle chamber 4. Perform cooling treatment to ensure the coolness of the air in the protective clothing 1. It should be noted that the walls of the cooling chamber 20 are inlaid with insulation partitions to ensure that the cold air of the refrigerant will not disperse to the outside.

Embodiment 3

[0044] Embodiment 3, on the basis of Embodiment 2, the switch of the middle chamber 4 and the switch of the cooling chamber 20 are solenoid valves, the inner louvers 12, the outer louvers 13, and the diversion louvers 19 are all electric louvers. The air treatment structure is a miniature air cleaner, which can be a CGJ-AW2-06 type air cleaner, or other common miniature air cleaners, the two exhaust fans 8, the air treatment structure, a plurality of The circulation fan blade 15 and a plurality of the electric louvers are electrically connected to the control module, the control module includes a control unit and a timing unit, and the control logic is pre-programmed in the control unit, so The control logic described is divided into the following three steps:

[0045] Step 1: Turn on the middle compartment 4 switch, inner louver 12, exhaust fan 8, air treatment structure, and cooling compartment 20, and close the circulation fan blade 15, circulation louver, and outer louver ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com