Atmospheric suspended matter sedimentation prevention and control equipment

A technology for settling equipment and suspended solids, which is applied in the field of air pollution control. It can solve the problems of no water spraying from the nozzle and the reduced settling effect of suspended solids, so as to achieve good settling effect and improve the settling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

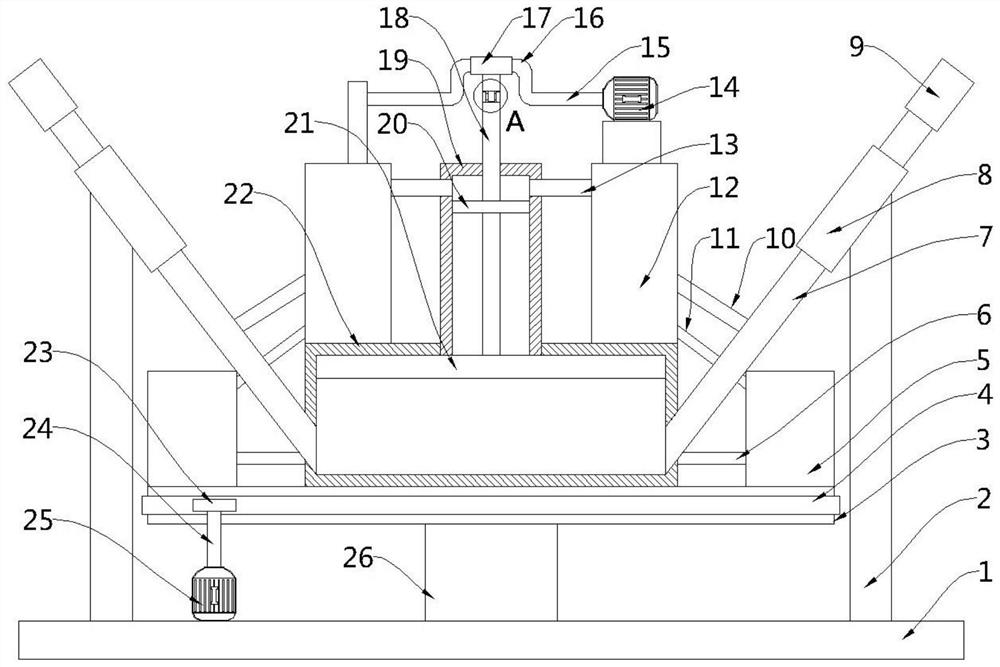

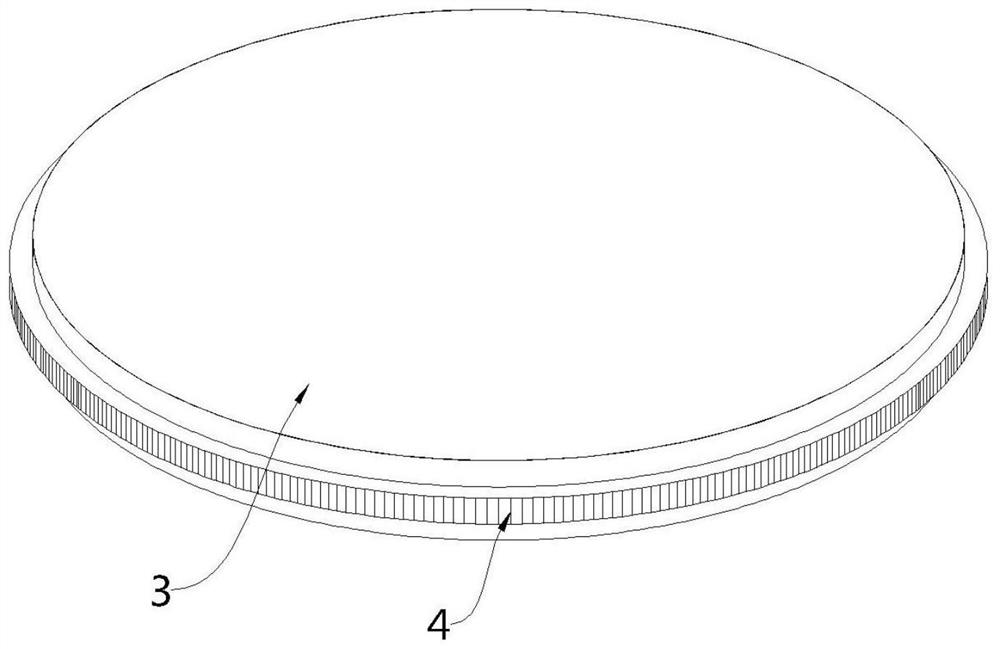

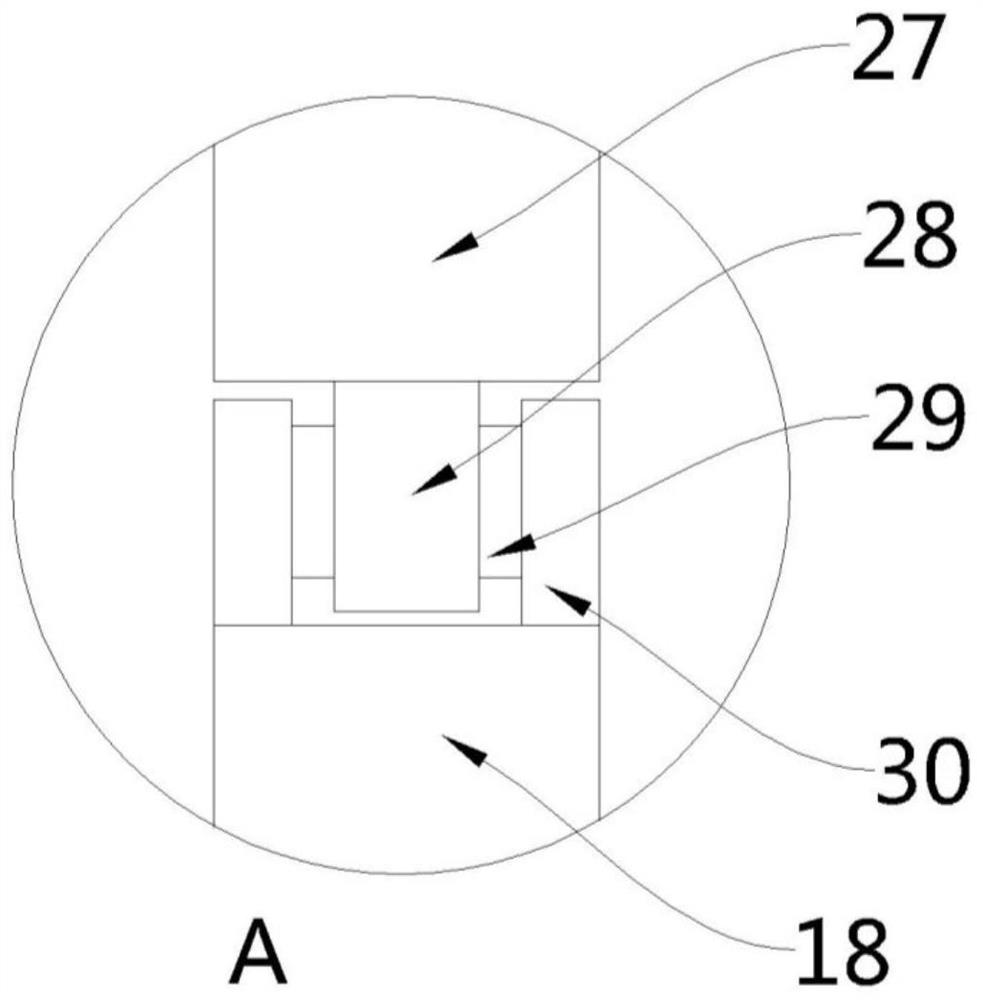

[0025] see Figure 1-3 , the present embodiment provides a settling prevention device for suspended solids in the atmosphere, which includes a bottom plate 1 and a support plate 3 rotatably arranged on the upper part of the bottom plate 1, and the upper part of the bottom plate 1 is provided with a second device for driving the support plate 3 to rotate. Drive assembly, the first water tank 5 and the second water tank 22 are fixedly arranged on the upper part of the support plate 3, the drive box 19 and the third water tank 12 are arranged on the upper part of the second water tank 22, the first water tank 5 and the second water tank The two water tanks 22 are communicated through the first water pipe 6, and the first water tank 5 and the third water tank 12 are communicated through the second water pipe 11. The side wall of the second water tank 22 is also communicated with a spray pipe 7. The third water tank 12 communicates with the spray pipe 7 through the third water tank...

Embodiment 2

[0038] see figure 1 , a kind of atmospheric suspended solids prevention and settlement equipment. Compared with Embodiment 1, the end of the spray pipe 7 away from the second water tank 22 is inclined upward in this embodiment, so that the water sprayed through the spray pipe 7 can flow toward the High-altitude spraying improves the settling effect of air-suspended solids.

[0039] The embodiment of the present invention has the advantage of good settling effect of suspended solids. The first driving assembly drives the driving rod 18 to move up and down, and then drives the first pressing plate 20 and the second pressing plate 21 to move up and down. When the first pressing plate 20 and the second pressing plate 21 move upward When moving, the second pressing plate 21 draws the water inside the first water tank 5 from the first water pipe 6 to the inside of the second water tank 22. At this moment, the first pressing plate 20 increases the pressure inside the third water tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com