Roving core-spun yarn manufacturing device

A core-spun yarn and roving technology, applied in the field of roving frame, can solve the problems of incapable of discharging sewage, inconvenient recycling, reducing the effect of batt and dust settlement, etc., and achieve the effect of improving the settlement effect and avoiding the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

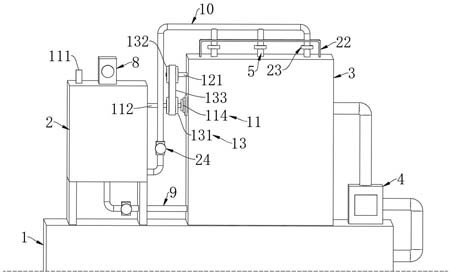

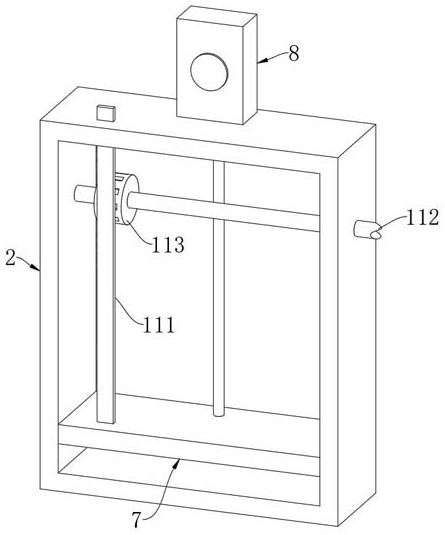

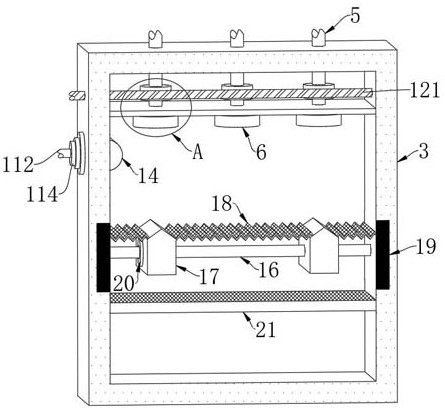

[0028] Such as Figure 1-5 As shown, a device for manufacturing roving core-spun yarn includes a roving frame main body 1, a water guide box 2, a dust removal box 3 and a dust collector 4 are fixedly connected to the roving frame main body 1, and the dust suction end of the dust collector 4 is connected to the roving The machine main body 1 is connected, and the output end of the dust collector 4 is connected with the dust removal box 3, and a plurality of drainage pipes 5 are connected in rotation in the dust removal box 3, and the lower end of the drainage pipe 5 is connected with a nozzle 6, and the setting of the nozzle 6 can make the water flow Better spraying, the piston plate 7 is slidably connected in the water guide box 2, and the upper end of the water guide box 2 is fixedly connected with the cylinder 8, the output end of the cylinder 8 is fixedly connected with the piston plate 7, and the cooperation of the cylinder 8 and the piston plate 7 can Regulate the air pre...

Embodiment 2

[0037] for Figure 6 The second embodiment shown is different from the first embodiment in that the filter screen 21 is sealed and slidably arranged in the dust removal box 3, and two support plates 25 are fixedly connected in the dust removal box 3, and there is a gap between the support plate 25 and the filter screen 21. A plurality of return springs 26 are fixedly connected, and a plurality of arc surfaces are arranged at intervals on the filter screen 21. The lower end of the slide plate 17 is fixedly connected with a connecting block 27, and the connecting block 27 is rotatably connected with a roller 28, and the roller 28 is in contact with the filter screen 21. Connection, through the cooperation of the provided roller 28 and the arc surface on the filter screen 21, the roller 28 can reciprocate and squeeze the filter screen 21 in the process of sliding with the slide plate 17, and at the same time, under the action of the return spring 26, the filter screen 21 can reci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com