Method of graded use of reverse flotation phosphorus concentrate pulp

A phosphate concentrate slurry and reverse flotation technology, applied in flotation, solid separation, cyclone devices, etc., can solve the problems that the quality of phosphate slurry does not meet the requirements, cannot produce high-quality phosphate phosphate fertilizer products, and high impurity content. , to achieve the effect of enhancing competitiveness and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

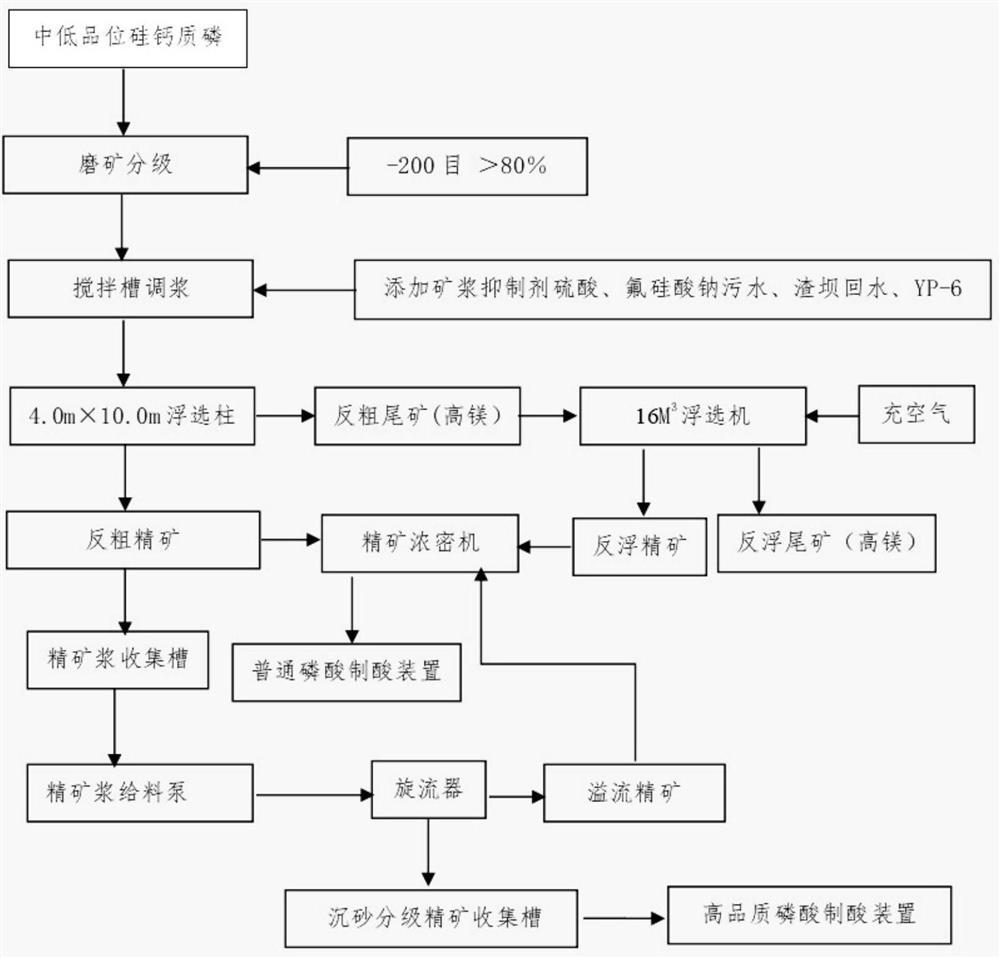

Method used

Image

Examples

Embodiment 1

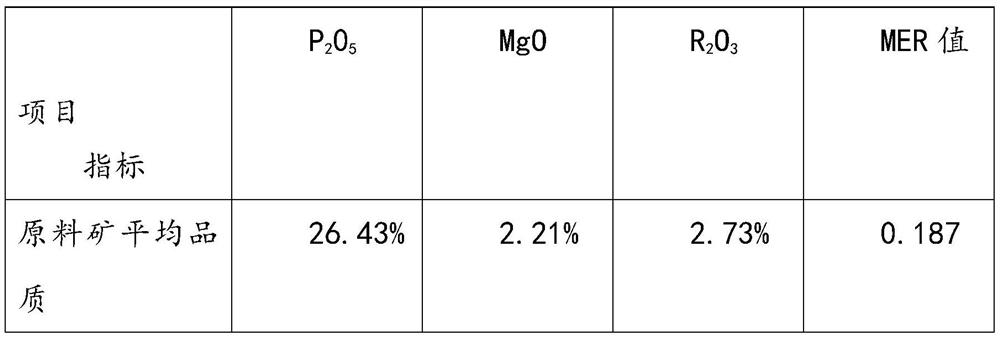

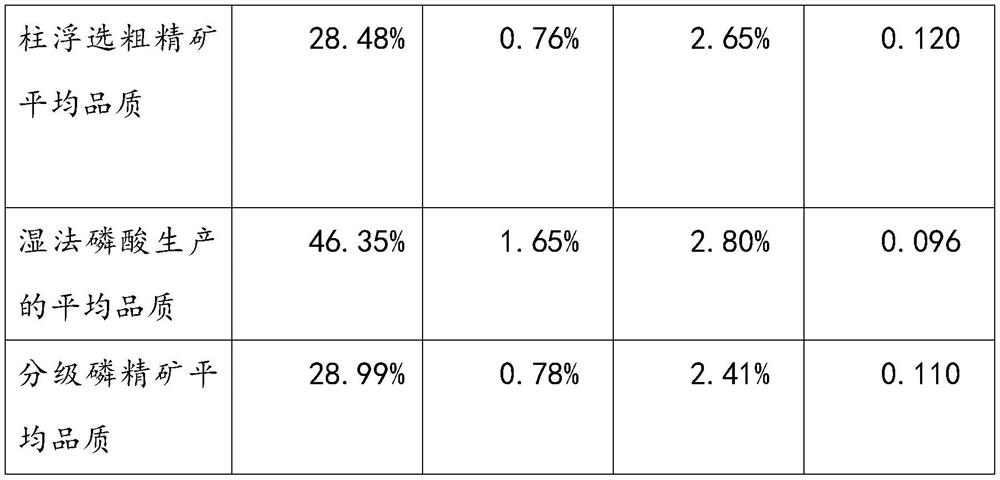

[0038] This embodiment production cycle is certain month 11-26 days, and the average quality of production input phosphate rock raw material ore is: P 2 0 5 content of 26.43%, MgO content of 2.21%, R 2 o 3 The content is 2.73%, MER value is 0.187; the average quality of column flotation rough concentrate is: P 2 0 5 content of 28.48%, MgO content of 0.76%, R 2 o 3 The content is 2.65%, and the MER value is 0.120; the average quality of the graded phosphorus concentrate after using this method to carry out cyclone classification again to the rough concentrate is: P 2 0 5 content of 28.99%, Mg0 content of 0.78%, R 2 o 3 The content is 2.41%, and the MER value is 0.110. The average quality of phosphoric acid used in wet-process phosphoric acid production is: P 2 0 5 content of 46.35%, Mg0 content of 1.65%, R 2 o 3 content of 2.80%, MER value 0.096; the average nitrogen content of diammonium phosphate (DAP) products produced is 17.52%, P 2 0 5 The content is 46.96%,...

Embodiment 2

[0043] This embodiment production cycle is certain month 3-12 days, and the average quality of production input phosphate rock raw material ore is: P 2 0 5 content of 26.88%, MgO content of 2.12%, R 2 o 3 The content is 2.48%, MER value is 0.171; the average quality of column flotation crude concentrate is: P 2 0 5 content of 28.93%, Mg0 content of 0.72%, R 2 o 3 The content is 2.31%, and the MER value is 0.105; the average quality of the graded phosphorus concentrate after using this method to classify the rough concentrate again is: P 2 0 5 content of 29.53%, Mg0 content of 0.75%, R 2 o 3 The content is 2.12%, and the MER value is 0.097. The average quality of phosphoric acid used in wet-process phosphoric acid production is: P 2 0 5 content of 47.33%, Mg0 content of 1.57%, R 2 o 3 The content is 2.58%, MER value is 0.088; The average nitrogen content of the produced diammonium phosphate (DAP) product is 18.02%, P 2 0 5 The content is 46.44%, and the total nut...

Embodiment 3

[0048] This embodiment production cycle is certain month 6-10 days, and the average quality of production input phosphate rock raw material ore is: P 2 0 5 content of 27.45%, MgO content of 2.08%, R 2 o 3 The content is 2.32%, MER value is 0.160; the average quality of column flotation rough concentrate is: P 2 0 5 content of 29.55%, Mg0 content of 0.66%, R 2 o 3 The content is 2.18%, and the MER value is 0.096; the average quality of the graded phosphorus concentrate after using this method to classify the coarse concentrate again is: P 2 0 5 content of 30.41%, Mg0 content of 0.70%, R 2 o 3 The content is 2.04%, the MER value is 0.090, and the phosphoric acid index produced by wet-process phosphoric acid is P 2 0 5 content of 50.03%, Mg0 content of 1.52%, R 2 o 3 content of 2.65%, MER value 0.083, the average nitrogen content of 66% monoammonium phosphate (MAP) produced is 11.06%, P 2 0 5 The content is 55.48%, the total nutrient is 66.54%, and the 66% nutrient ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com