A condition-independent identification method of milling cutter wear state based on spindle drive current

A technology of spindle drive and wear state, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve problems such as interfering with the normal processing of machine tools, and achieve the effect of reducing workpiece scrap rate and machine tool failure rate, and reducing factory costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings. The following examples are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

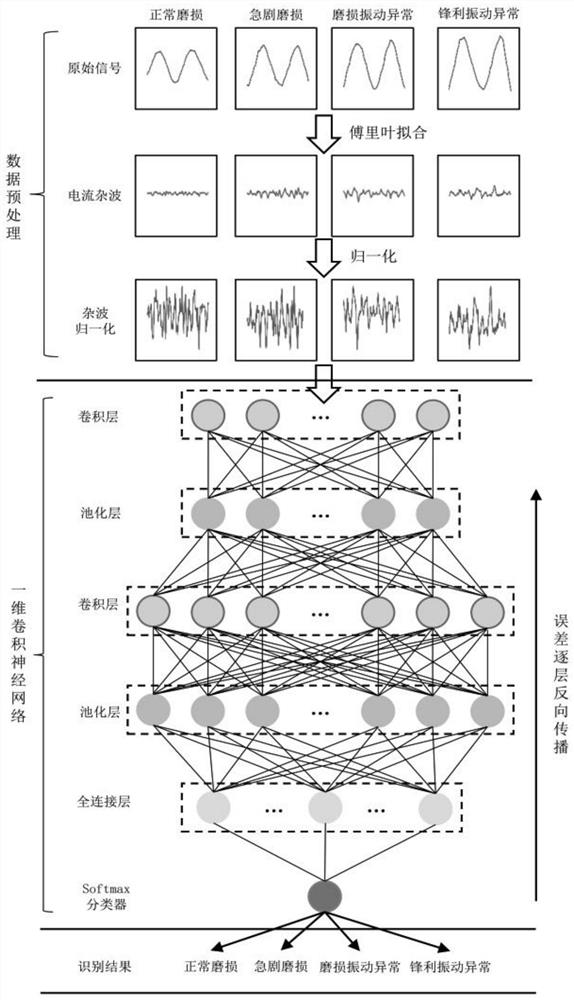

[0020] Such as figure 1 Shown is the flow chart of the identification of tool wear state in the present invention. The present invention provides a milling cutter wear state identification method based on spindle driving current that is independent of working conditions, including the following steps:

[0021] a. Collect the original signal of the spindle drive current and the vibration signal of the spindle during metal milling;

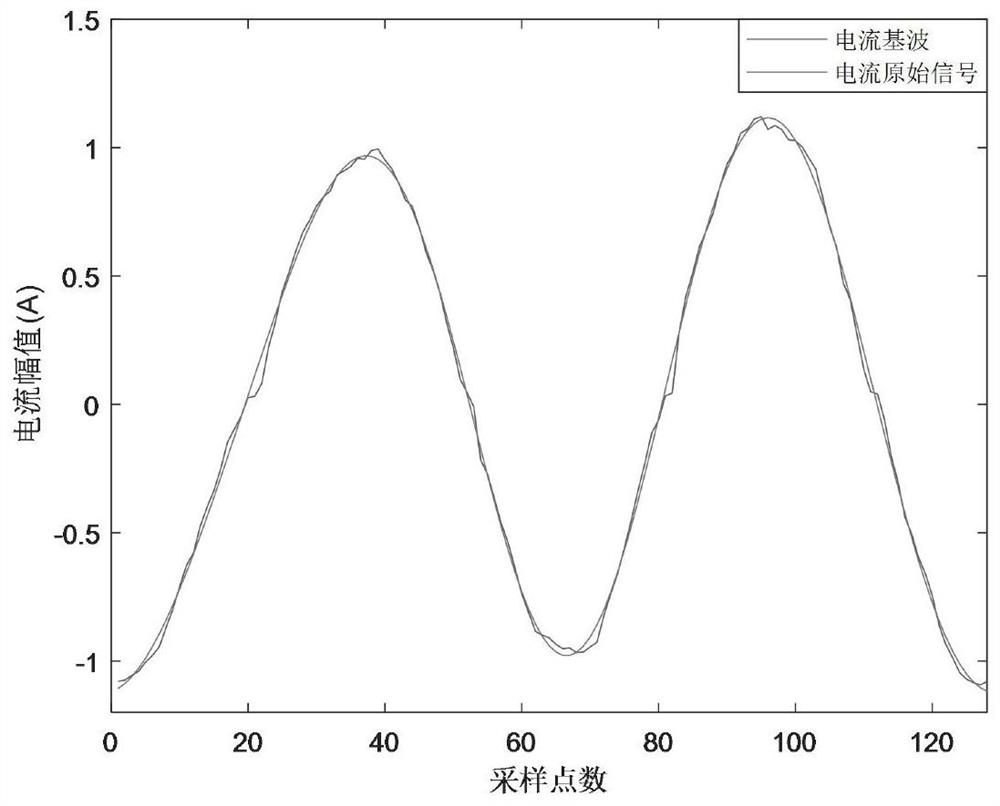

[0022] b. Fit the original signal of the collected spindle drive current through Fourier series fitting to obtain a spindle drive current clutter signal that has nothing to do with the working condition;

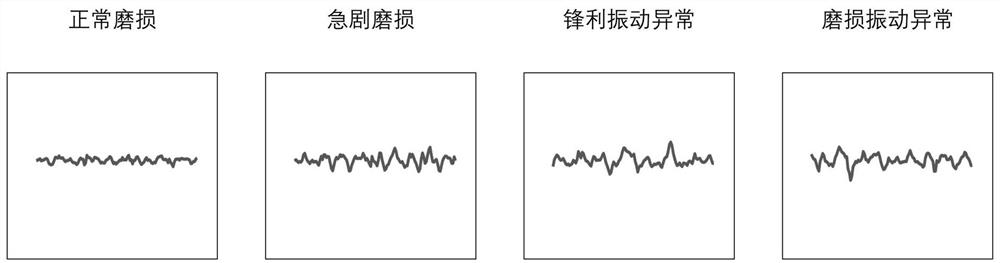

[0023] c. Normalize the acquired clutter signals so that all signal amp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com