Product-in-process automatic demolding mechanism for expansion and contraction assembly drum and control method thereof

A technology of automatic demolding and forming drum, applied in the direction of presses, manufacturing tools, etc., can solve the problems of strong dependence on the operation level of the staff, increase the labor cost of the enterprise, low automation level, etc., to improve the degree of automation and production efficiency, The effect of reducing labor costs and reducing labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with embodiment the present invention is described in further detail.

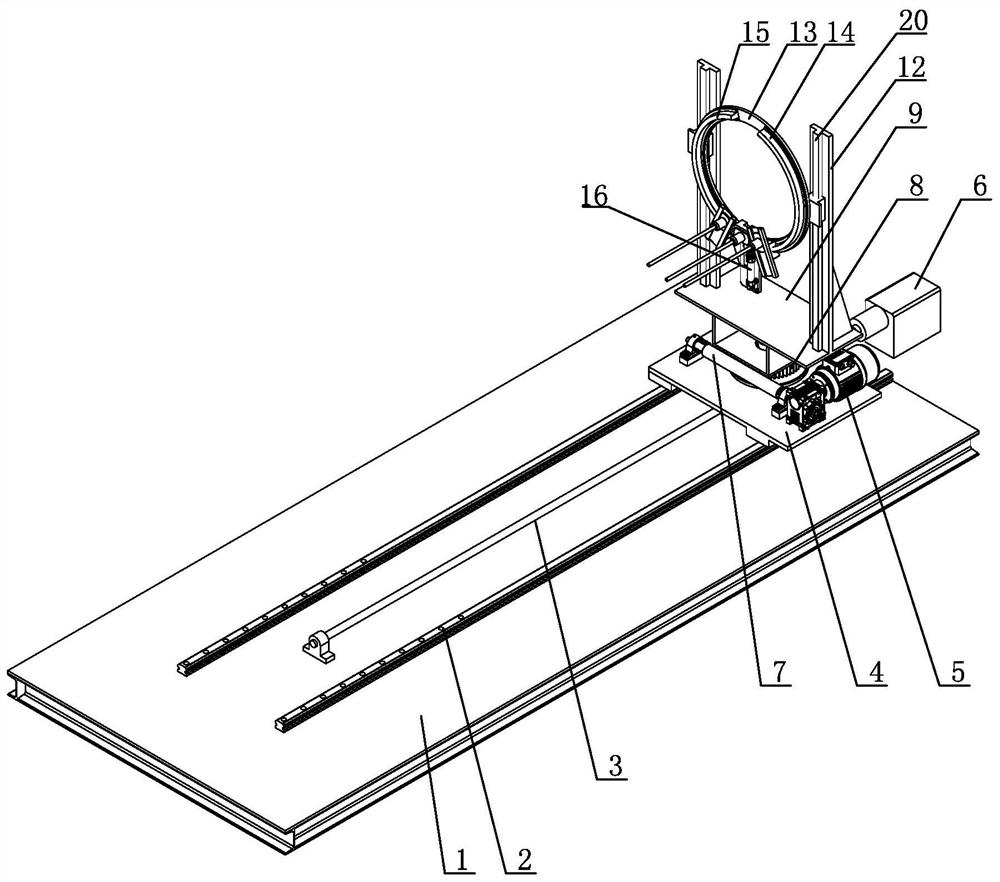

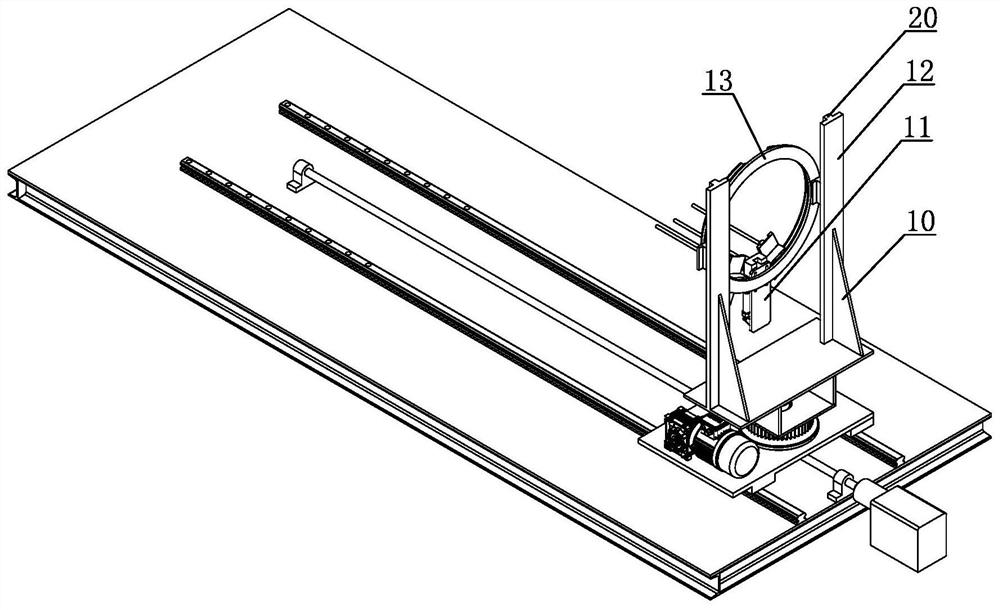

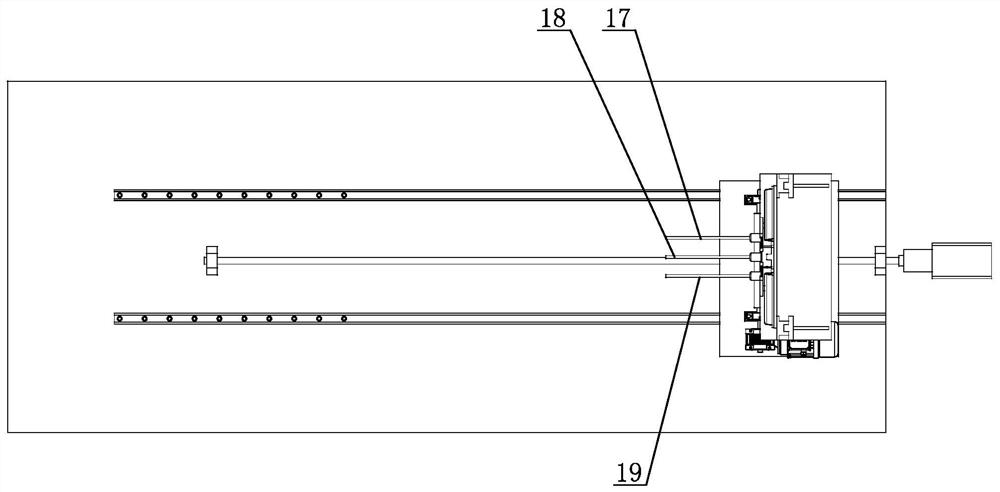

[0030] This embodiment proposes a kind of expansion and contraction forming drum automatic demoulding mechanism for WIP, such as Figures 1 to 3 As shown, it includes base 1, linear guide rail 1, linear guide rail 2 20, screw rod 3, movable seat 4, rotary table drive motor 5, movable seat drive motor 6, worm rod 7, turbine 8, rotary table 9, ribs 10. Mounting plate 11, column 12, demoulding ring 13, left arc-shaped cylinder 14, right arc-shaped cylinder 15, bottom demoulding rod lifting cylinder 16, right demoulding rod 17, bottom demoulding rod 18 and left demoulding rod 19.

[0031] Two linear guide rails 1 are installed on the base 1, the screw rod 3 is installed between the two linear guide rails, the moving seat 4 is placed on the linear guide rail 1 2, and screwed with the screw rod 3, driven by the driving motor 6 of the moving seat , so that the moving seat 4 moves alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com