Alkali-free setting accelerator, and preparation method and application thereof

A technology of accelerator and stabilizer, applied in the field of alkali-free accelerator and its preparation, can solve the problems of long setting time, decline of impermeability level, large dosage, etc., and achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

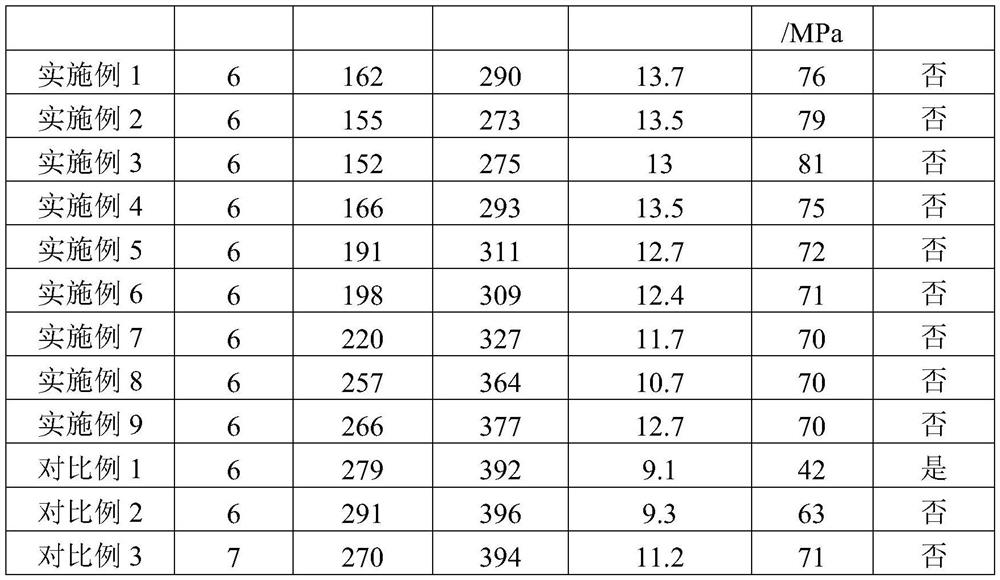

Examples

Embodiment 1

[0032] Step 1, mixing sodium metaaluminate with water to obtain a sodium metaaluminate solution;

[0033] Step 2, adding aluminum sulfate to the sodium metaaluminate solution in 3 times to obtain solution I; wherein, stirring for 20 minutes after adding aluminum sulfate each time, the amount of adding aluminum sulfate for the first time is 25% by weight of the total amount of aluminum sulfate The amount of adding aluminum sulfate for the second time is 50% by weight of the total amount of aluminum sulfate, and the amount of adding aluminum sulfate for the last time is 25% by weight of the total amount of aluminum sulfate;

[0034] Step 3, adding fluosilicic acid and hydroxymethylcellulose (complexing stabilizer) to solution I in sequence;

[0035] Wherein, based on the total weight of the alkali-free quick-setting agent, the consumption of sodium metaaluminate is 22% by weight, the consumption of aluminum sulfate is 40% by weight, the consumption of fluosilicic acid is 33% by ...

Embodiment 2

[0037] Step 1, mixing sodium metaaluminate with water to obtain a sodium metaaluminate solution;

[0038] Step 2. Add aluminum sulfate to the sodium metaaluminate solution in 4 times to obtain solution I. After adding aluminum sulfate each time, stir for 20 minutes. The amount of aluminum sulfate added for the first time is 10% by weight of the total amount of aluminum sulfate. The amount of adding aluminum sulfate for the second time and the third time is 40% by weight of the total amount of aluminum sulfate, and the amount of adding aluminum sulfate for the last time is 10% by weight of the total amount of aluminum sulfate;

[0039] Step 3, adding fluosilicic acid and hydroxymethylcellulose to solution I in sequence;

[0040] Wherein, based on the total weight of the alkali-free quick-setting agent, the consumption of sodium metaaluminate is 22% by weight, the consumption of aluminum sulfate is 40% by weight, the consumption of fluosilicic acid is 33% by weight, and the cons...

Embodiment 3

[0042] Step 1, mixing sodium metaaluminate with water to obtain a sodium metaaluminate solution;

[0043] Step 2, adding aluminum sulfate to the sodium metaaluminate solution in 5 times to obtain solution I; wherein, stirring for 20 minutes after adding aluminum sulfate each time, the amount of adding aluminum sulfate for the first time is 10% by weight of the total amount of aluminum sulfate , the amount of adding aluminum sulfate for the second time is 30% by weight of the total amount of aluminum sulfate, the amount of adding aluminum sulfate for the third time is 30% by weight of the total amount of aluminum sulfate, the amount of adding aluminum sulfate for the fourth time is all sulfuric acid 20% by weight of the total amount of aluminum, the amount of adding aluminum sulfate for the last time is 10% by weight of the total amount of aluminum sulfate;

[0044] Step 3, adding fluosilicic acid and hydroxymethylcellulose to solution I in sequence;

[0045] Wherein, based on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com