Double-degree-of-freedom torque motor based on annular air gap

A torque motor and degree of freedom technology, applied in the field of electro-hydraulic servo control components, can solve the problem that torque motors cannot meet the feedback requirements at the same time, and achieve the effects of large rotation angle, increased inclination angle, and low processing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

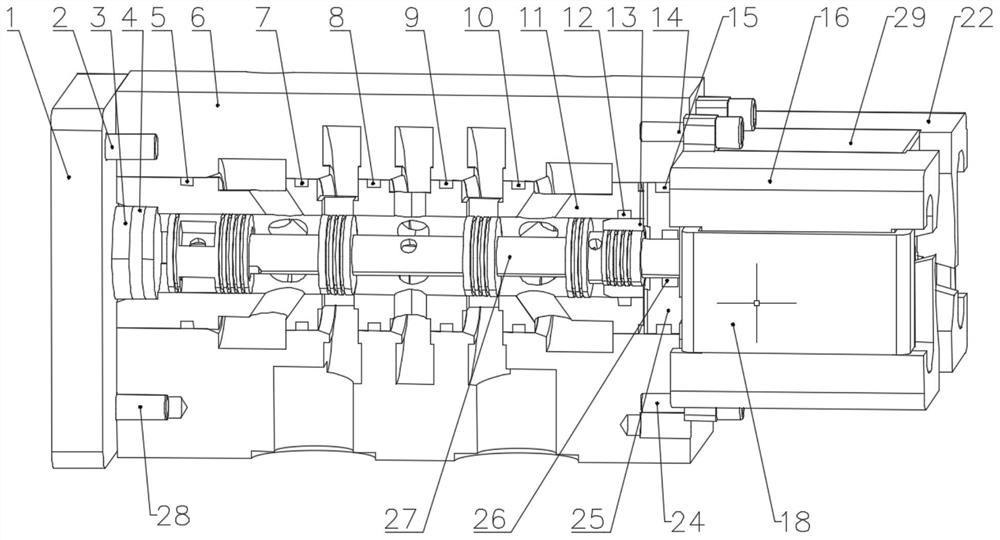

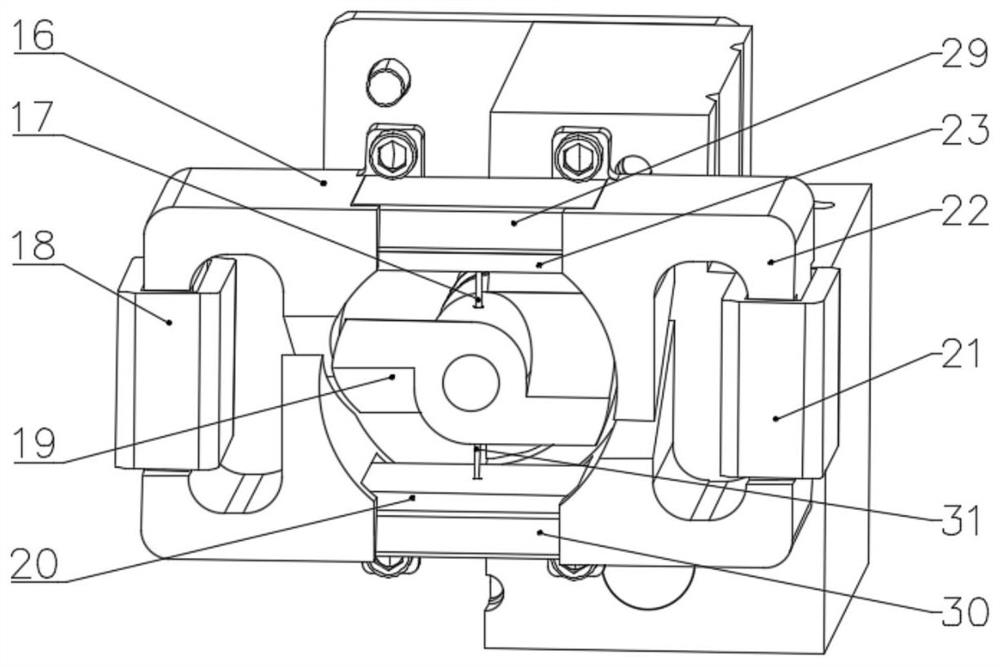

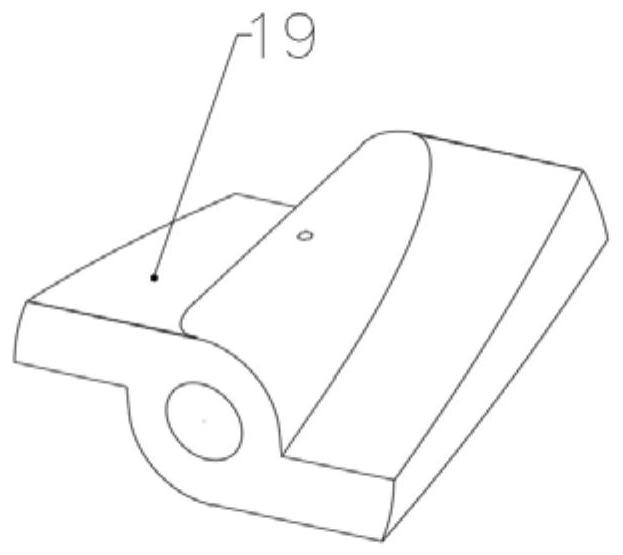

[0029] refer to Figure 1 ~ Figure 1 0, a new dual-degree-of-freedom torque motor based on an annular air gap, including a new dual-degree-of-freedom torque motor and a hydraulically amplified part. The novel dual-degree-of-freedom torque motor consists of a first yoke 16, a second yoke 22, an armature 19, a first permanent magnet 29, a second permanent magnet 30, a first spring rod 17, a second spring rod 31, and a first coil 18. , the second coil 21, the first spring top plate 20, the second spring top plate 23 and fixing screws and the like.

[0030]The first yoke 16 and the second yoke 22 are symmetrically arranged on both sides of the armature 19, and the first yoke 16 and the second yoke 22 are in a mirror image relationship on the vertical plane passing through the rotating shaft of the armature 19, and the direction close to the armature 19 is Inside, and vic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com