A distributed geared motor energy monitoring system and method

A technology for geared motors and monitoring systems, which is applied in control/regulation systems, signal transmission systems, electric components, etc., and can solve the problems of insufficient energy monitoring of distributed geared motors, increasing the service life of batteries in power supply units, and inability to provide on-site power supply, etc. , to reduce the cost of power supply deployment, prevent gears from getting stuck, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

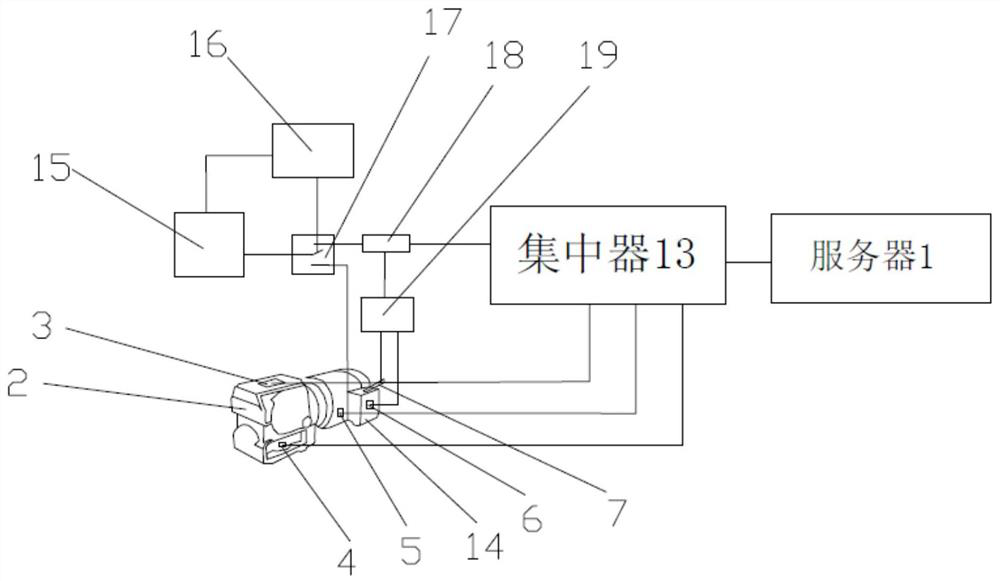

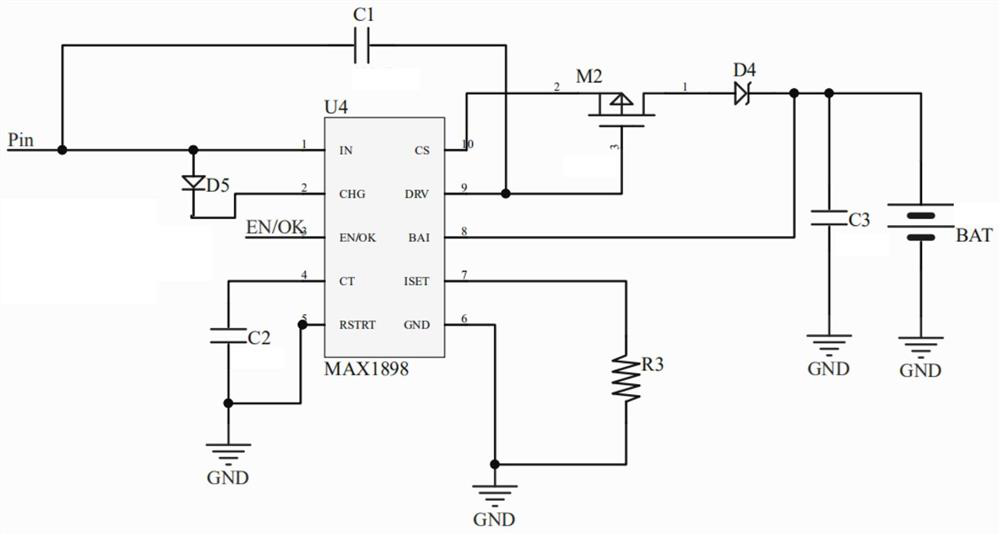

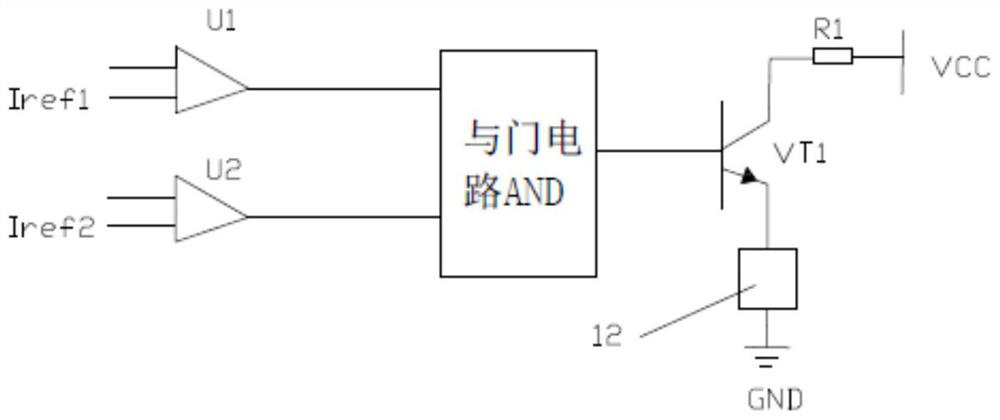

[0038] Embodiment 1: A distributed geared motor energy monitoring system, such as figure 1 As shown, it includes a gear motor 2, a vibration sensor 3, an oil temperature sensor 4, a winding temperature sensor 5, a power supply device 14, a current transformer 6, a voltage probe 7, a server 1, a power supply unit 15, a control module 19, a relay 18, The battery management system 16, the switch 17 and the concentrator 13, the vibration sensor 3 and the winding temperature sensor 5 are all installed on the geared motor 2, the vibration sensor 3 detects the vibration amplitude of the geared motor 2, and the vibration sensor 3 communicates with the concentrator through the wireless communication unit 13 is connected, the oil temperature sensor 4 detects the oil pool temperature of the geared motor 2, the oil temperature sensor 4 is connected to the concentrator 13 through the wireless communication unit, the winding temperature sensor 5 detects the winding temperature of the geared ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com