Detection system and method for muddy water interface in thickener

A technology of detection system and concentrator, which is applied in the direction of displaying liquid level indicator through pressure measurement, etc., can solve the problems of difficult to form a clear solid-liquid interface, complex particle size composition of coal slime, short particle settling time, etc. Wide temperature range, strong high pressure overload capability, good long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

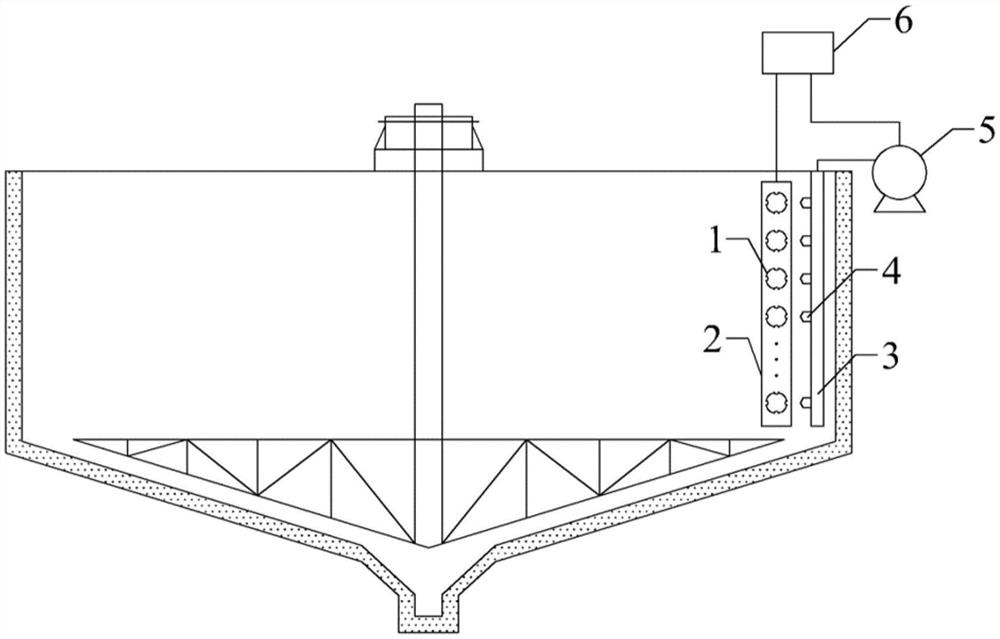

[0018] Such as figure 1 As shown, the present invention provides a kind of detection system of mud-water interface in the concentrator, comprises the pressure detection device that is made up of ceramic pressure sensor 1 and fixed pole plate 2, the cleaning device that is made up of pipeline 3, nozzle 4 and water pump 5, and The controller 6; the pressure detection device is installed vertically on the inner wall of the concentrator, and the cleaning device is installed on the side of the pressure detection device, and the controller 6 is connected with the pressure detection device and the cleaning device.

[0019] As a preferred embodiment of the present invention, the pressure detection device contains a plurality of ceramic pressure sensors 1, and the ceramic pressure sensors 1 are vertically embedded and installed on the fixed pole plate 2 with a spacing of 50 mm. The wires are connected by shielded wires. Machine depth is determined.

[0020] As a preferred embodiment o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com