Binary variable gray scale method in high-precision laser engraving rubber platemaking

A laser engraving, high-precision technology, used in printing plate preparation, image data processing, printing, etc., can solve the problems of slow speed and low precision, and achieve the goal of improving quality and speed, accurate and rapid area, and preventing repeated marking of boundary points. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described in detail below in conjunction with the accompanying drawings. These implementation examples are described in sufficient detail to enable those skilled in the art to practice the invention.

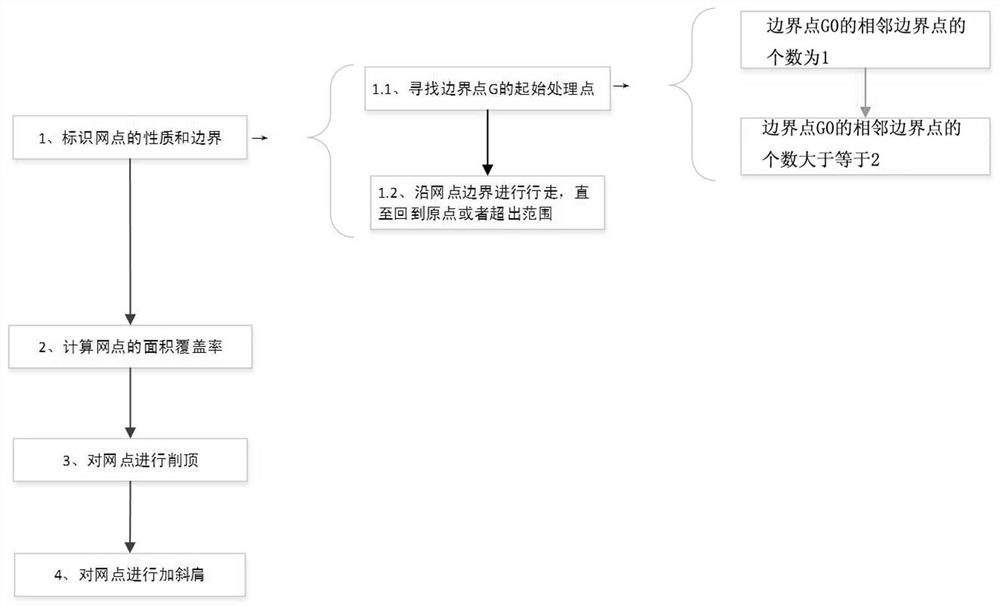

[0056] The present invention proposes a binary grayscale method in high-precision laser engraving rubber plate-making. The idea of the method is as follows:

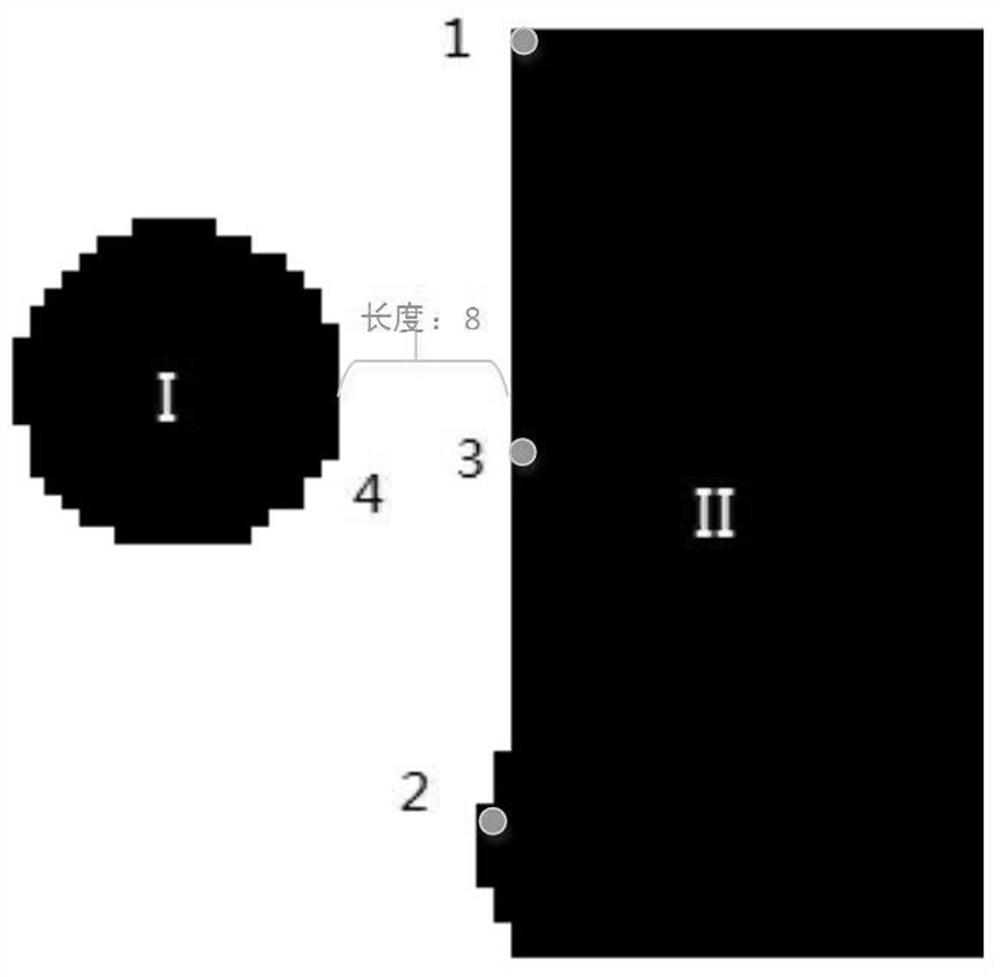

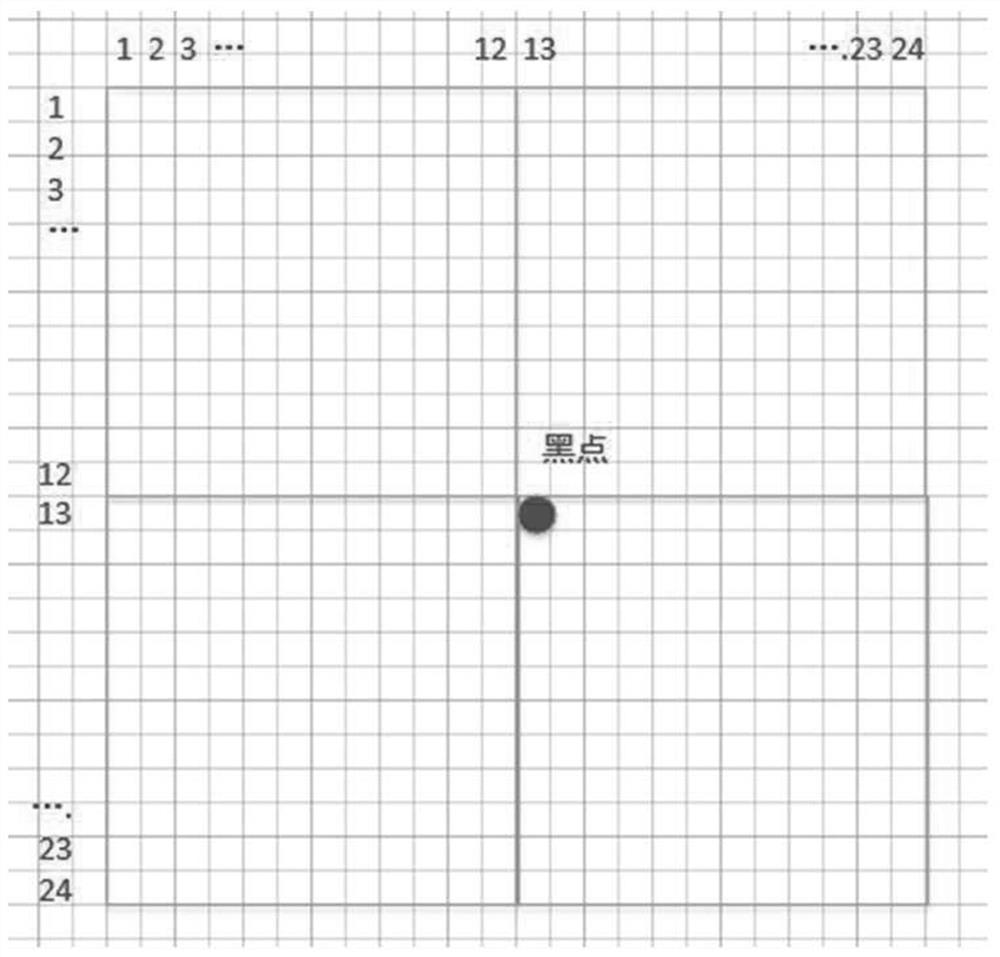

[0057] For a binary image, we traverse from top to bottom and left to right. Whenever a black dot is encountered, start to judge whether the black dot is a dot boundary point, that is, judge whether there is a white dot or no pixel on the top, bottom, left, and right sides of the black dot. Whenever a border point is traversed, it can be considered as a border point of a network point. Starting from the boundary point of the network point, walk (traverse) step by step along the boundary point of the network point in a certain direction. If it can return to the starting point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com