Magnetic material size defect detection method and device, detection equipment and readable storage medium

A defect detection and magnetic material technology, applied in the field of image processing, can solve problems such as high labor intensity, low detection efficiency, and difficulty in controlling detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

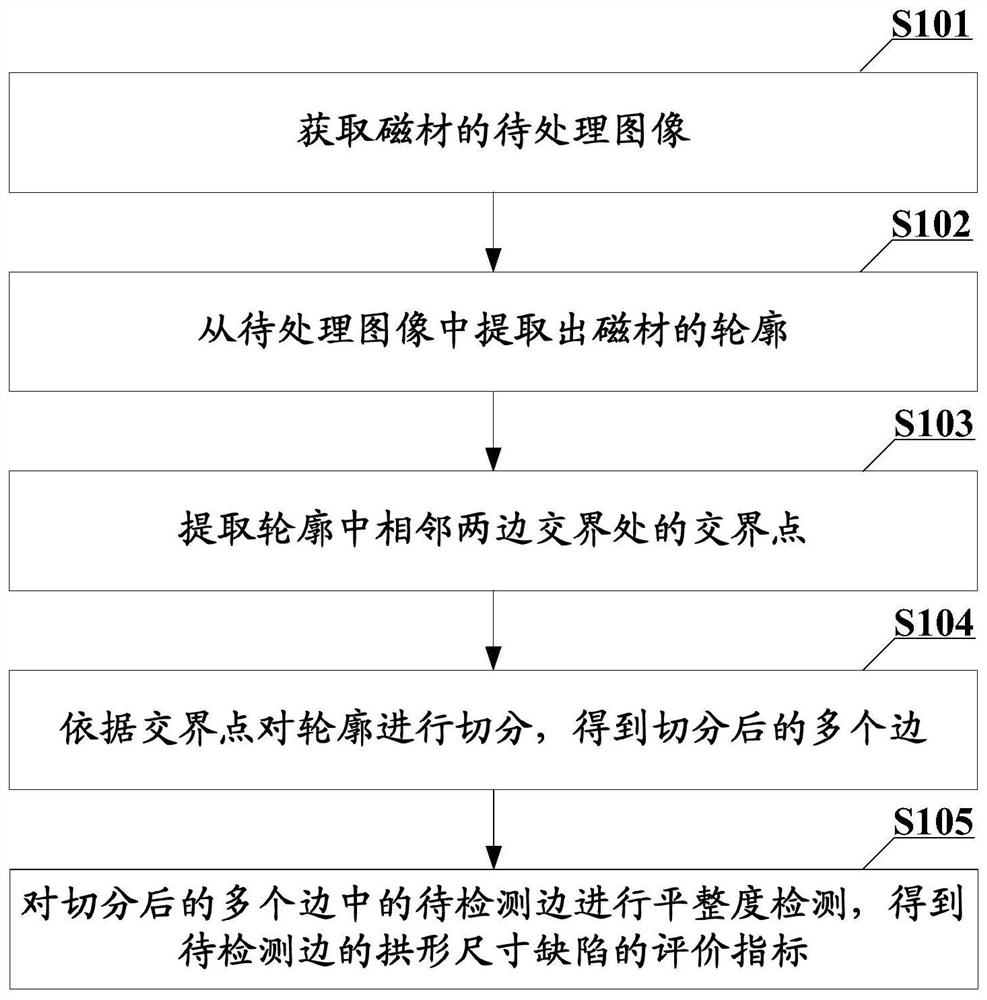

[0041] In the embodiment of the present application, a method for detecting size defects of magnetic materials is provided, see figure 1 shown, including:

[0042] S101: Acquire the image to be processed of the magnetic material.

[0043] In the embodiment of the present application, the image to be processed of the magnetic material (that is, the magnetic material) to be detected can be obtained by shooting with equipment such as an industrial camera. Generally, images captured by equipment such as industrial cameras are color images, but in order to facilitate image processing, in this embodiment of the application, the color images can be converted into grayscale images, and then processed.

[0044] S102: Extract the outline of the magnetic material from the image to be processed.

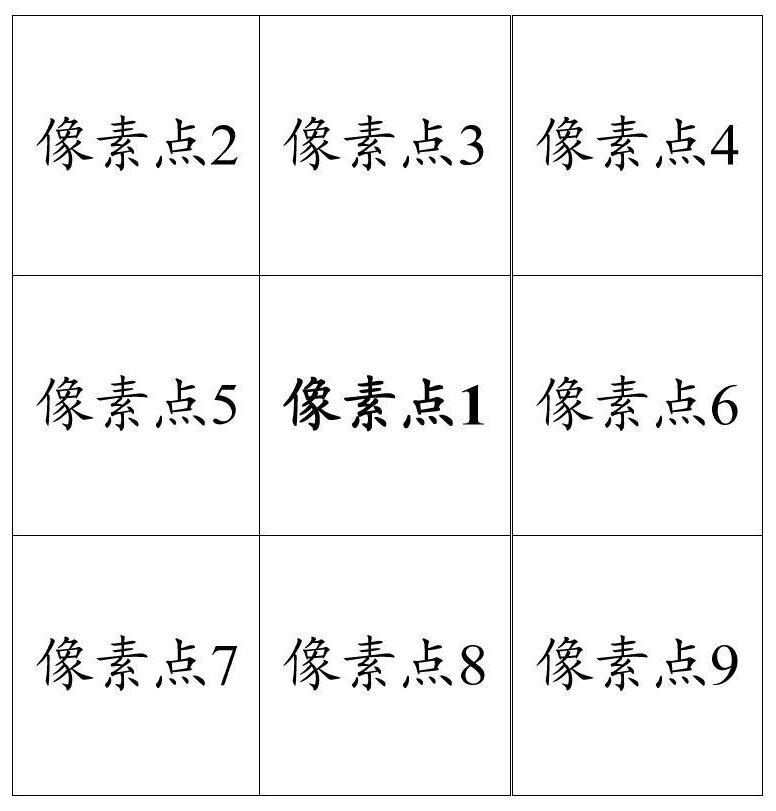

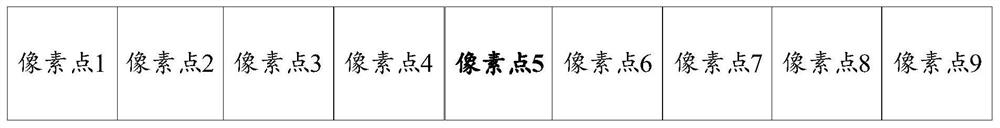

[0045] In order to facilitate the extraction of the outline of the magnetic material from the image to be processed, in the embodiment of the present application, the gray value of the edge po...

Embodiment 2

[0096] In this embodiment, on the basis of the first embodiment, a specific magnetic material size defect detection process is taken as an example to illustrate the solution of the present application.

[0097] The first step is to extract the outline of the magnetic material:

[0098] see Figure 4 as shown, Figure 4 It is the magnetic material image captured by the industrial camera, recorded as ORIGIN_IMAGE.

[0099] First, use a 0-degree second-order filter to filter the magnetic material image ORIGIN_IMAGE to obtain ImgW1, a 45-degree second-order filter to filter the magnetic material image ORIGIN_IMAGE to obtain ImgW2, and a 90-degree second-order filter to obtain ImgW2. The material image ORIGIN_IMAGE is filtered to obtain ImgW3, and a 135-degree second-order filter is used to filter the magnetic material image ORIGIN_IMAGE to obtain ImgW4.

[0100] Then, the image Image is obtained by the following formula:

[0101]

[0102] Perform second-order Gaussian filte...

Embodiment 3

[0116] Based on the same inventive concept, an embodiment of the present application also provides a magnetic material size defect detection device. see Figure 9 as shown, Figure 9 A magnetic material size defect detection device 100 corresponding to the method shown in the first embodiment is shown. It should be understood that the specific functions of the magnetic material size defect detection device 100 can refer to the above description, and in order to avoid repetition, the detailed description is appropriately omitted here. The magnetic material size defect detection device 100 includes at least one software function module that can be stored in a memory in the form of software or firmware or solidified in the operating system of the magnetic material size defect detection device 100 . specifically:

[0117] see Figure 9 As shown, the magnetic material size defect detection device 100 includes: an acquisition module 101 , an extraction module 102 , a segmentatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com