Industrial robot operation and maintenance practical training platform

A technology of industrial robots and training platforms, applied in the fields of instruments, simulators, space navigation equipment, etc., can solve the problems of a single variety of teaching tools and equipment, which is not conducive to improving learning progress, and is not conducive to controlling knowledge points of other tools and equipment, etc. Achieve the effect of improving learning progress and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

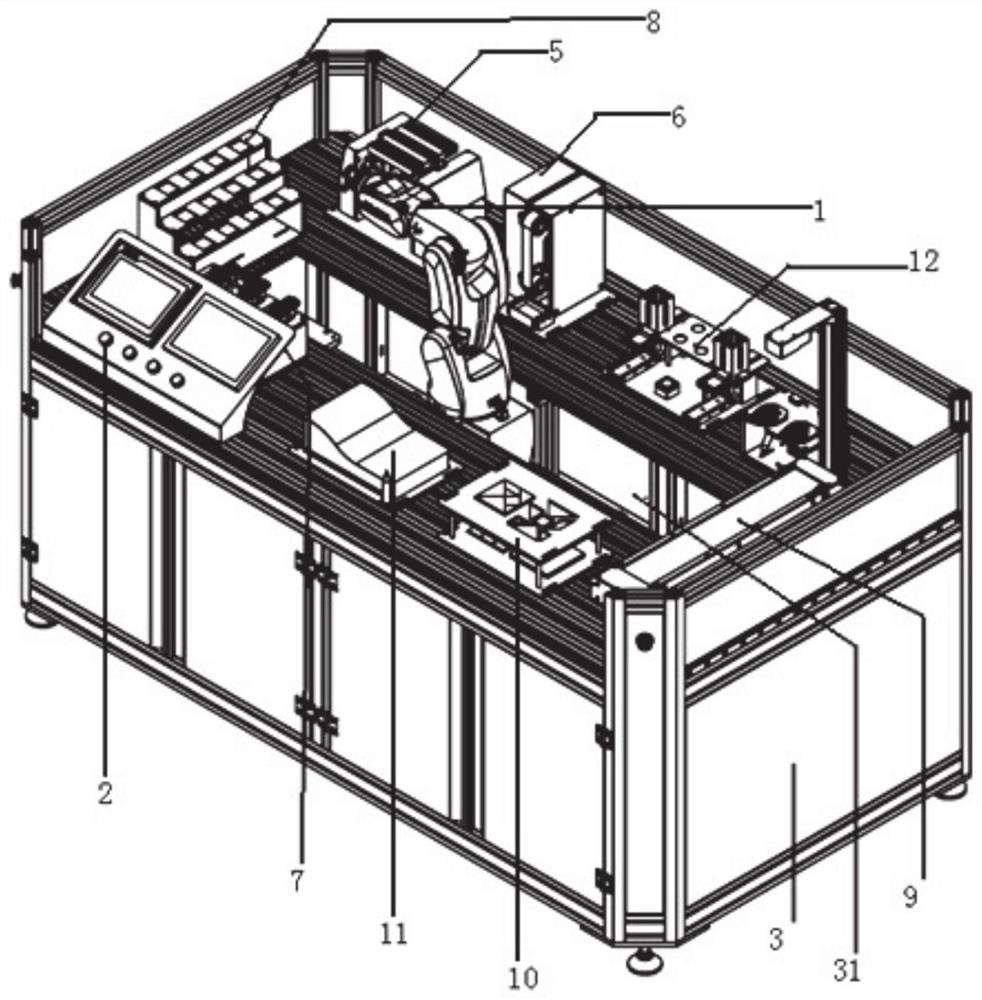

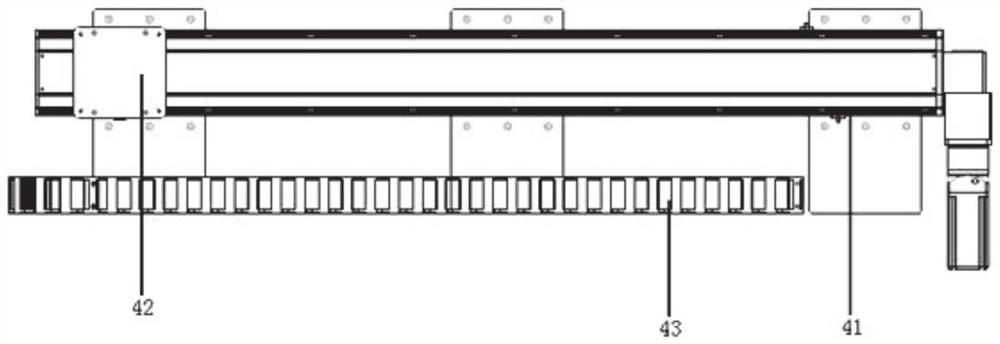

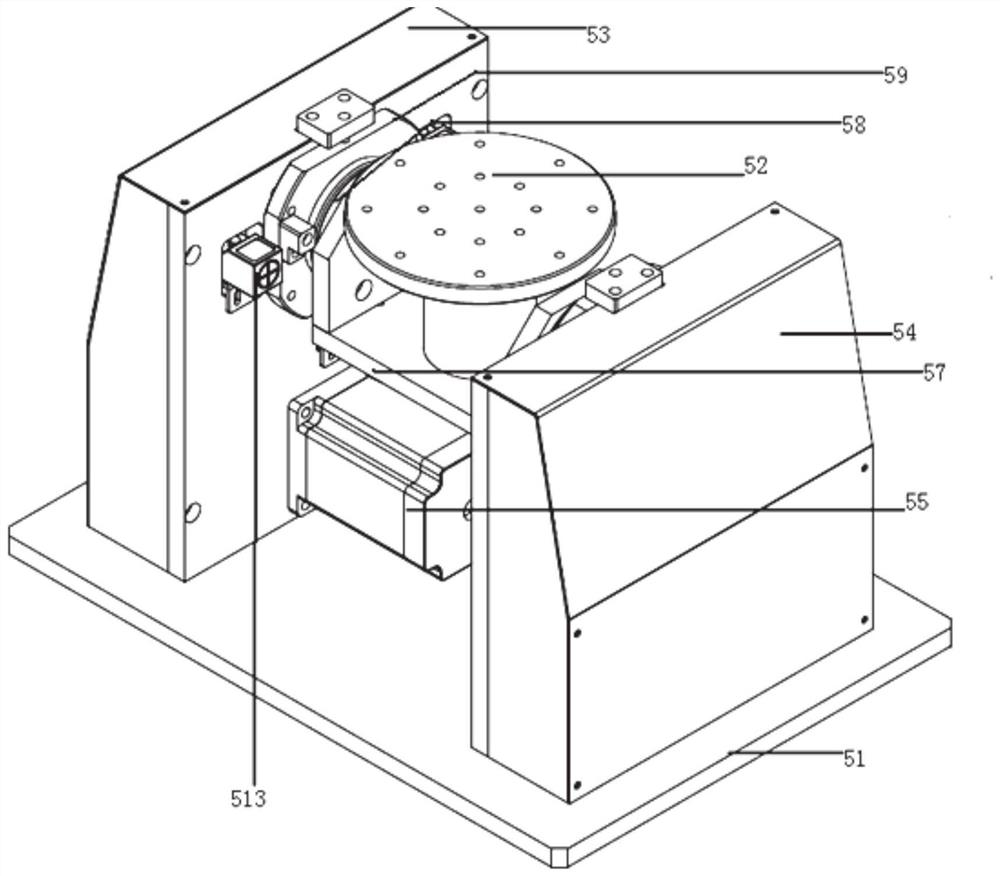

[0030] figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, an industrial robot operation and maintenance training platform, including a six-joint teaching industrial robot body 1, a PLC touch screen Table 3, walking module 4, welding module training equipment 5, abrasive belt grinding module training equipment 6, quick-change fixture module training equipment 7, assembly module training equipment 12, six-joint teaching industrial robot body 1 control signal input terminal and PLC touch screen module 2. The control signal output terminal is electrically connected through the data line; it also has a vertical library module training device 8, a visual delivery module training device 9, a palletizing and jigsaw puzzle module training device 10, and a curved surface marking module training device 11; the training platform 3 is a rectangular hollow structure 31 in the middle, and the upper end of the training platform 3 is a rectangular coherent structure; the walking module 4 is hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com