A cylindrical battery sealing steel ball fixture tray mechanism

A technology for cylindrical batteries and fixture trays, which is applied to battery pack parts, electrolyte battery manufacturing, non-aqueous electrolyte batteries, etc. It can solve the problems of no positioning function and difficult simultaneous attitude adjustment of multiple batteries, and meet the requirements of loading scalability needs, meet the needs of posture adjustment, and achieve obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

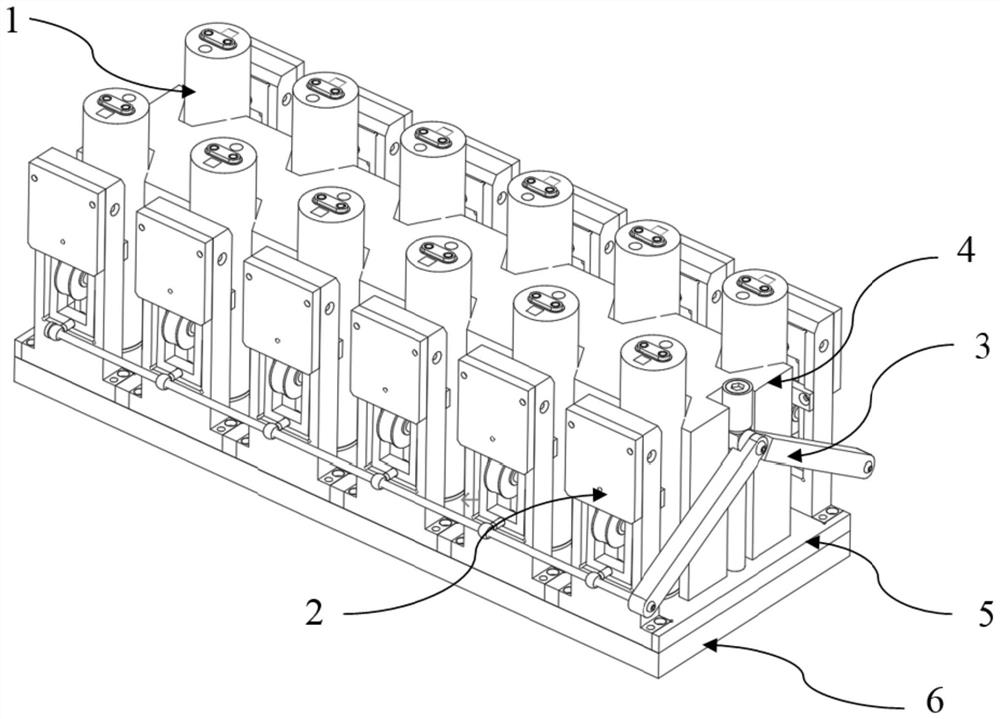

[0030] Example 1, see figure 1 , a cylindrical battery sealing ball fixture tray mechanism, including a bottom plate, the bottom plate includes a first bottom plate 5 above and a second bottom plate 6 below, the first bottom plate 5 is made of PE material, and is fixedly connected with the second bottom plate 6 .

[0031] A base block 4 is fixed on the bottom plate, and at least one first notch 27 for accommodating the cylindrical battery 1 is provided longitudinally on the lateral side of the base block 4, and a frame body 7 fixed on the bottom plate is provided outside the first notch 27 The first baffle plate 11 is fixed on the laterally outer surface of the frame body 7, and the inside of the frame body 7 is movably connected with a laterally rotating side clip assembly 2, and a first elastic spring is connected between the side clip assembly 2 and the first baffle plate 11. Part 13.

[0032] In this embodiment, one of the lateral sides of the base block 4 ( figure 1 A f...

Embodiment 2

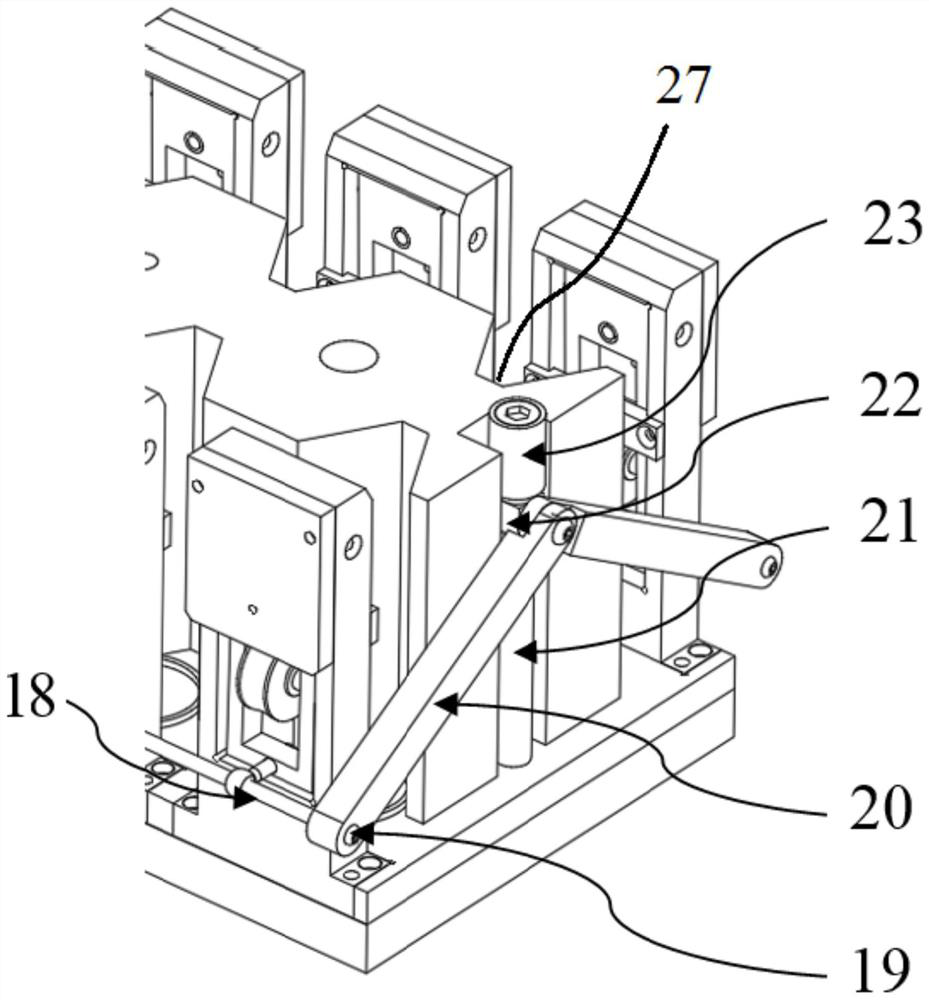

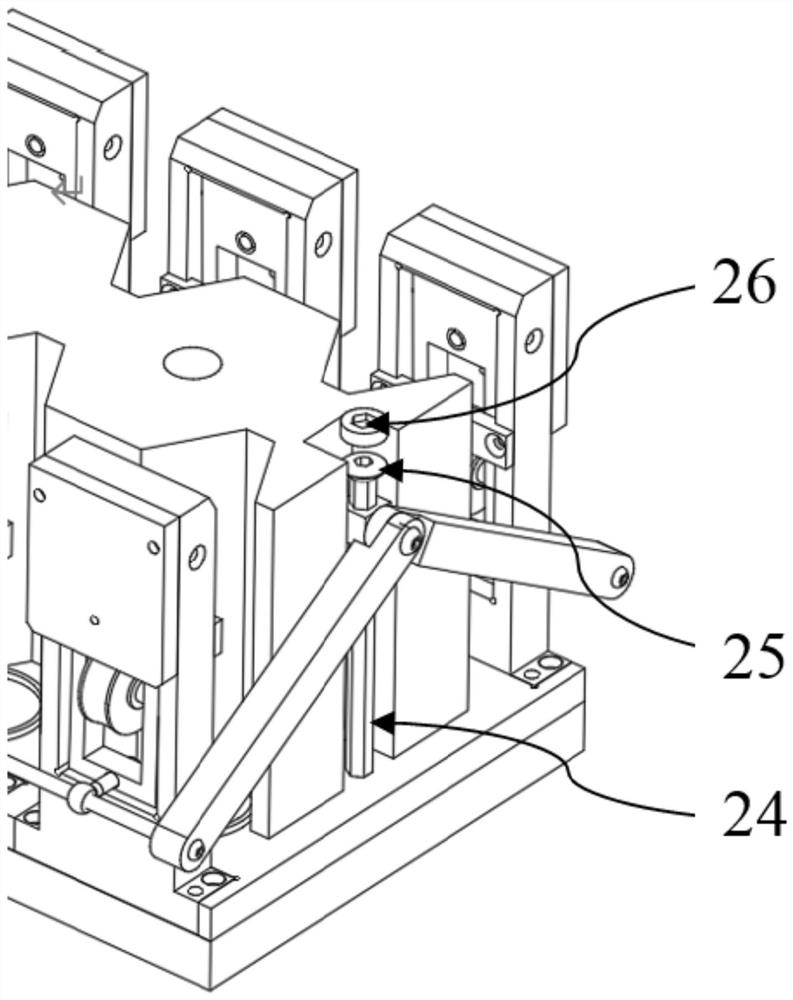

[0038] Example 2, such as Figure 2-3 As shown, further, a column 24 is also fixed on the bottom plate, and the top of the column 24 is movably connected with an adjustment assembly along the height direction, and the adjustment assembly and the side clamp assembly 2 are connected through a linkage assembly 3, and the linkage assembly 3 includes that when the adjustment assembly descends, The side clamp assembly 2 rotates laterally outward to release the first state of the cylindrical battery 1 , and when the adjustment assembly rises, the side clamp assembly 2 rotates inward to press the cylindrical battery 1 in the second state.

[0039] Preferably, the column 24 is arranged on one side of the longitudinal surface of the base block 4 ( figure 1 What is shown is the front side of the base block 4, and it can also be arranged on the rear side of the base block 4), so as to facilitate the common connection of the linkage assembly 3, the adjustment assembly, and the side clamp a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com