Stator structure of cylindrical linear motor

A linear motor and stator structure technology, which is applied in the direction of magnetic circuit shape/style/structure, electrical components, electromechanical devices, etc., can solve the problems of poor heat dissipation conditions of the motor, high processing cost, and large stator quality, and reduce processing costs , contribute to heat dissipation, reduce the quality of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

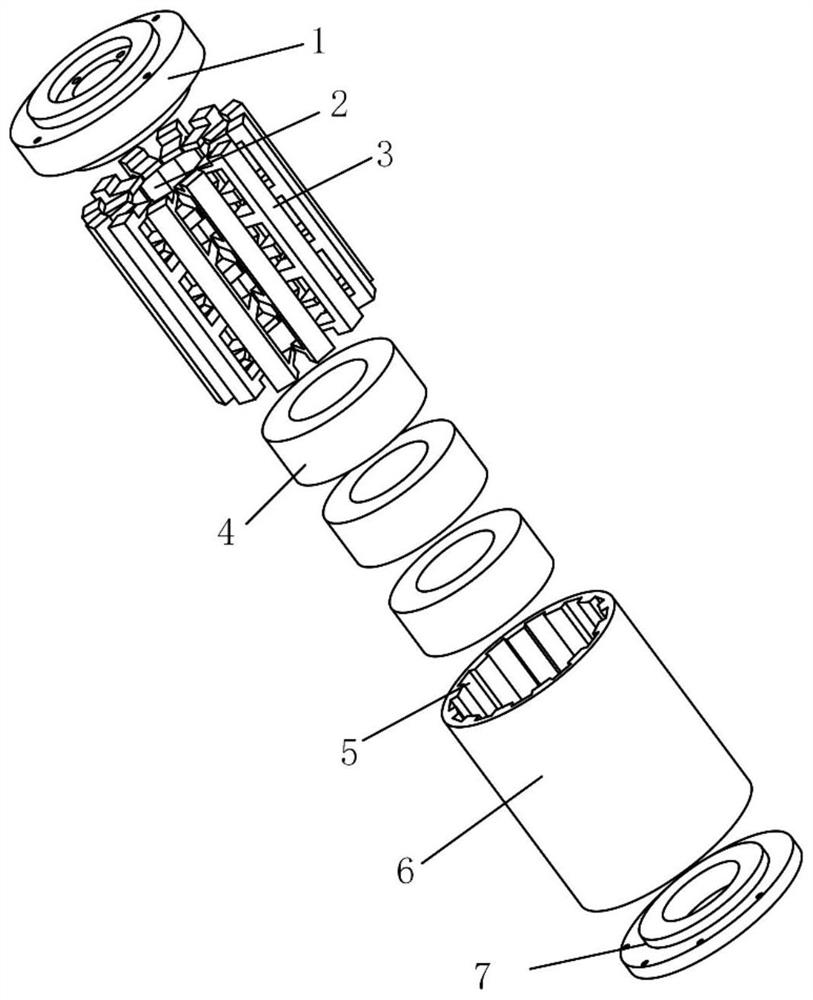

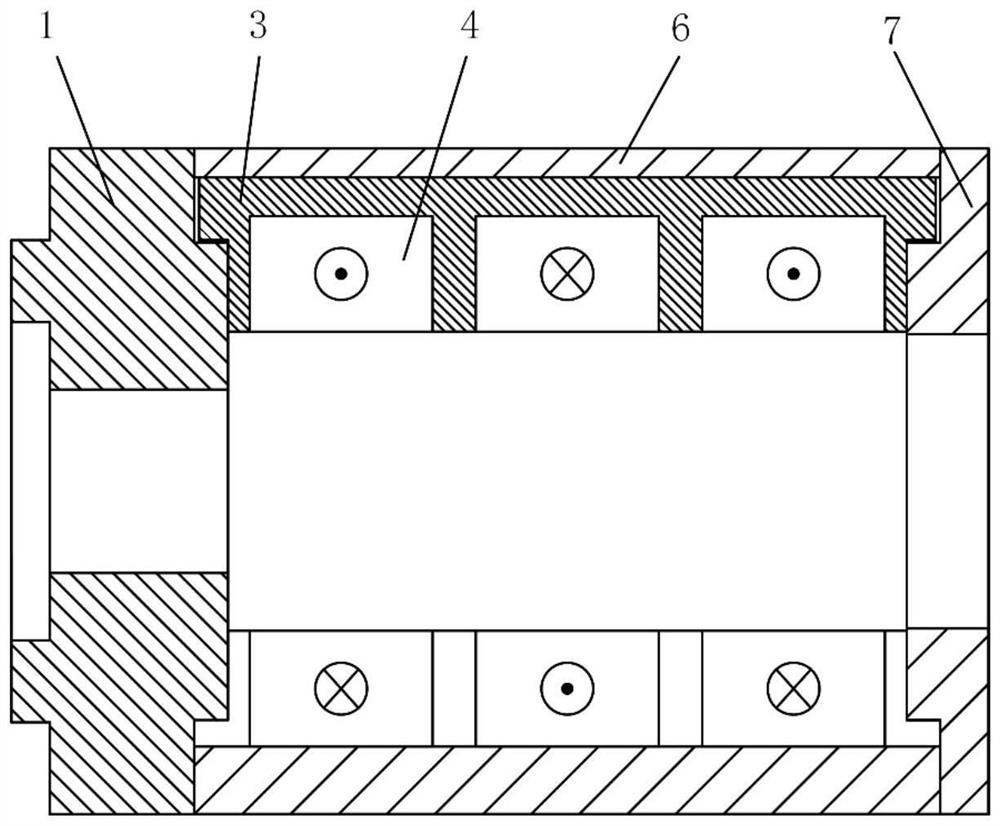

[0025] Such as Figure 1-4 As shown, a stator structure of a cylindrical linear motor includes a motor casing 6, the bottom of the motor casing 6 is connected to the lower end cover 7 through fasteners, and the coil winding 4 and the stator core 3 are sequentially loaded into the cavity. , the top is connected with the upper end cover 1 through fasteners;

[0026] The stator core 3 includes a stator core block 31 , and a plurality of stator slots 2 are opened on one end of the stator core block 31 .

[0027] The coil winding 4 is placed in the stator slot 2 of the stator core 3 .

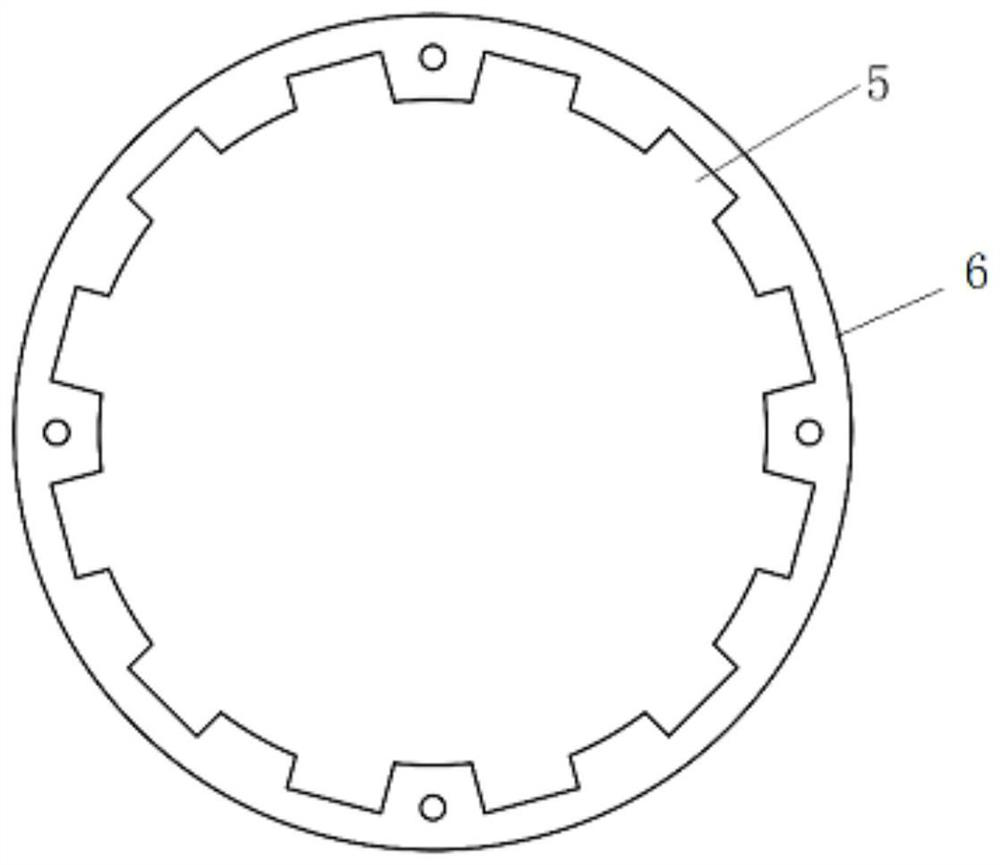

[0028] The inner side of the motor casing 6 is provided with several toothed grooves 5 uniformly distributed in the circumferential direction for placing the stator core 3 .

[0029] The stator core block 31 is formed by laminating silicon steel sheets along the circumferential direction.

[0030] The stator core block 31 is located in the cavity of the iron core 3 .

[0031] The number of stato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com