Flow guiding and classifying mechanism for collecting natural rubber

A technology of natural rubber and collection mechanism, which is applied in application, forestry, agriculture, etc. It can solve the problems of falling impurities and poor collection effect, and achieve the effect of reducing the contact area and improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

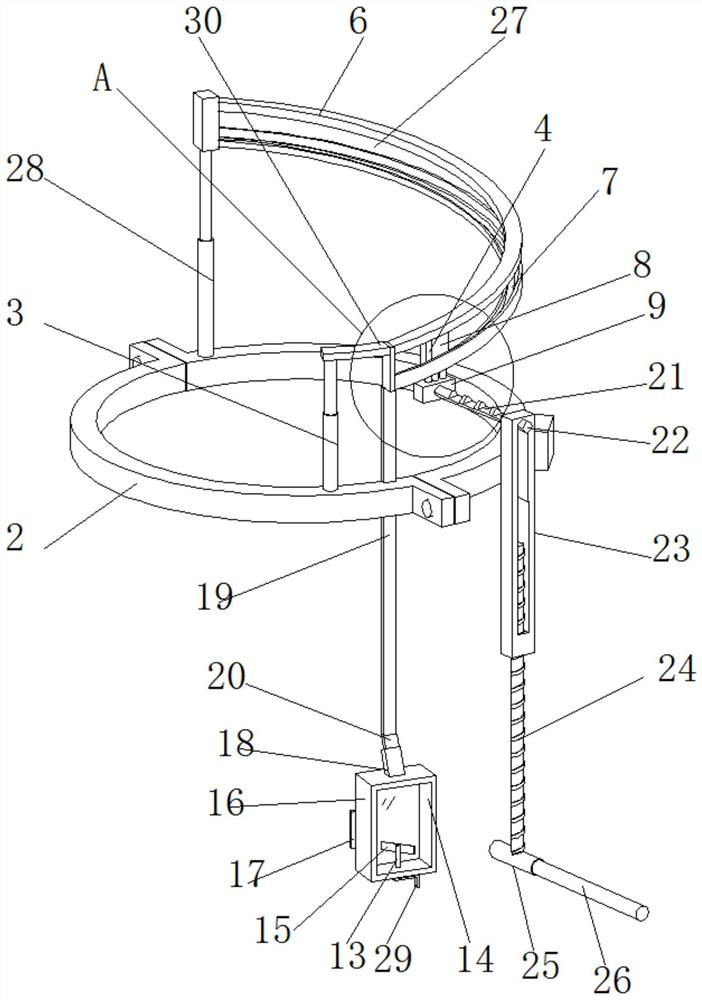

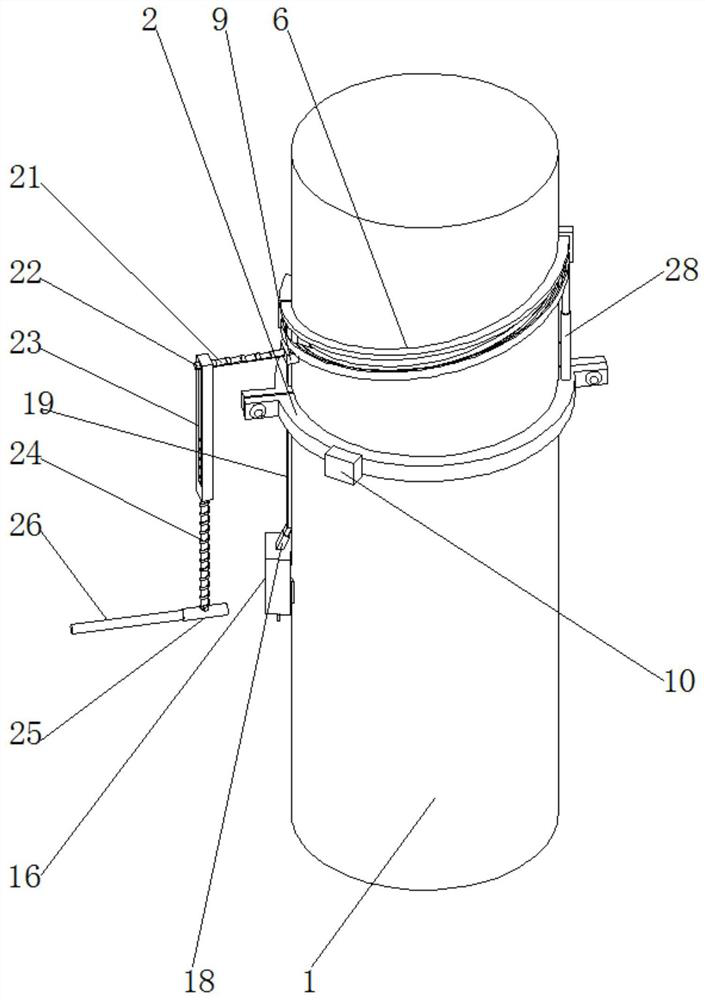

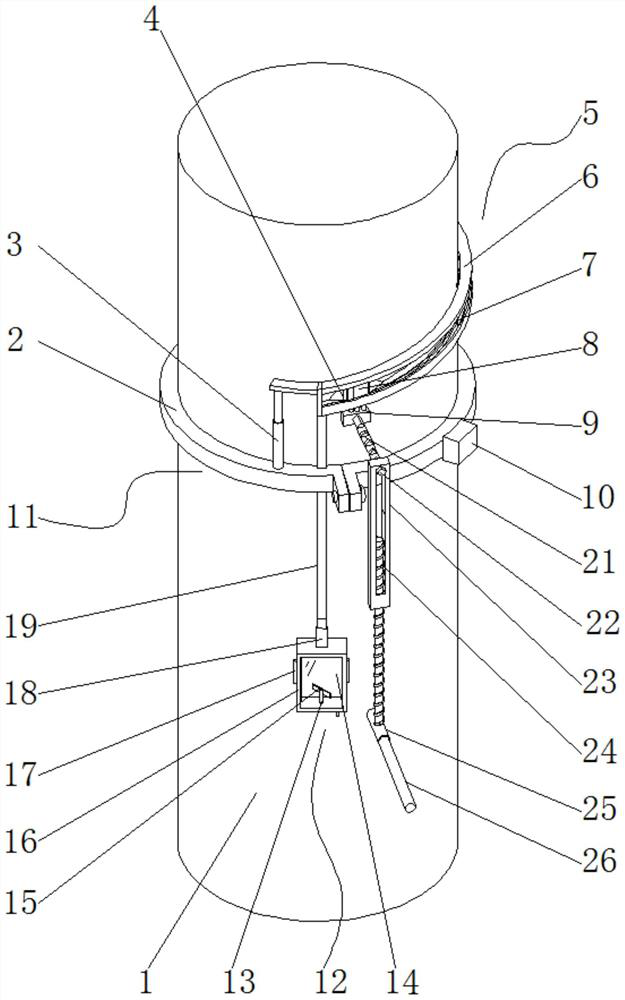

[0024] Embodiments of the present invention provide a cutting mechanism and method for collecting natural rubber at high places, such as Figure 1-6 As shown, it is set on rubber tree 1. It includes a collecting mechanism 12 and a fixing component 11, and the fixing component 11 is arranged on the rubber tree 1. The collecting mechanism 12 is arranged on the fixing assembly 11 . The collecting mechanism 12 includes a shroud 19 , an oblique port 20 , a box body 16 , a connecting head 18 , a fixing plate 17 , a glass 14 , a fan blade 15 , a rotating rod 13 and a handle 29 . Fixed plate 17 is arranged on the low place of rubber tree 1. The box body 16 is detachably clamped on the fixing plate 17 , and the connector 18 is arranged on the top of the box body 16 and communicates with the box body 16 . The shroud 19 is vertically inserted on the surface of the rubber tree 1 . One end opening of the shroud 19 corresponds to the through hole at the lowest point of the spiral slidew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com