Dispersion equipment for nano-alloy material

A nano-alloy, dispersing technology, applied in mixers, shake/oscillation/vibration mixers, mixers with rotary stirring devices, etc., can solve the problem that the quality of nano-materials does not meet the requirements and affect the soft agglomerate disintegration of nano-alloy materials. Agglomeration process, loss of dispersing ability and other problems, to achieve the effect of improving the efficiency and quality of deagglomeration and eliminating the phenomenon of standing waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

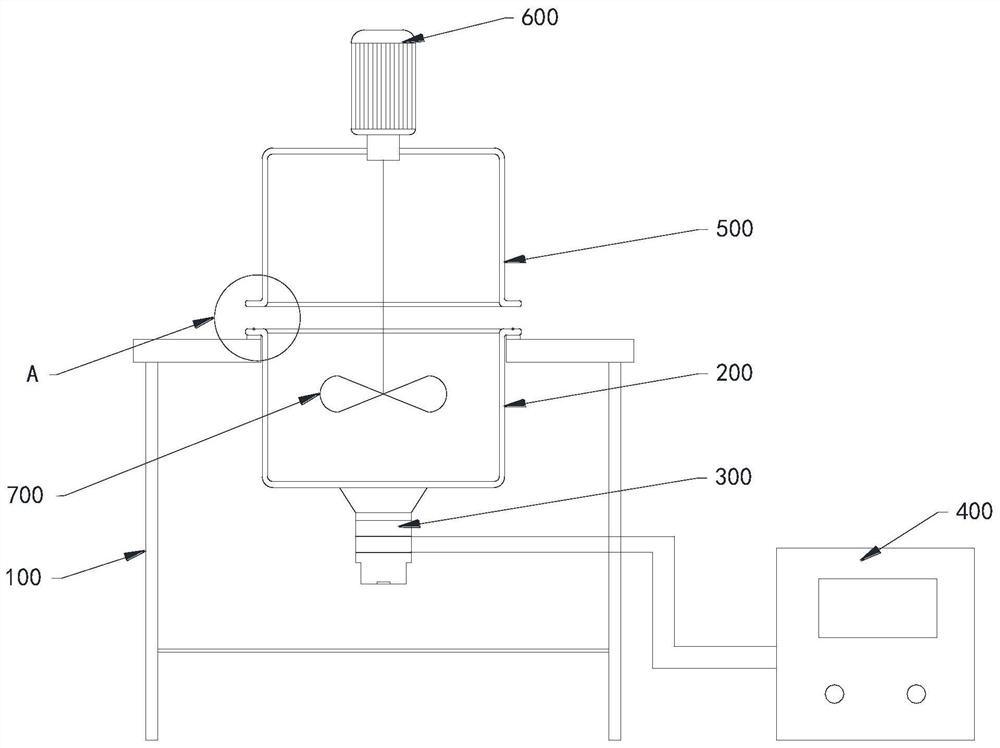

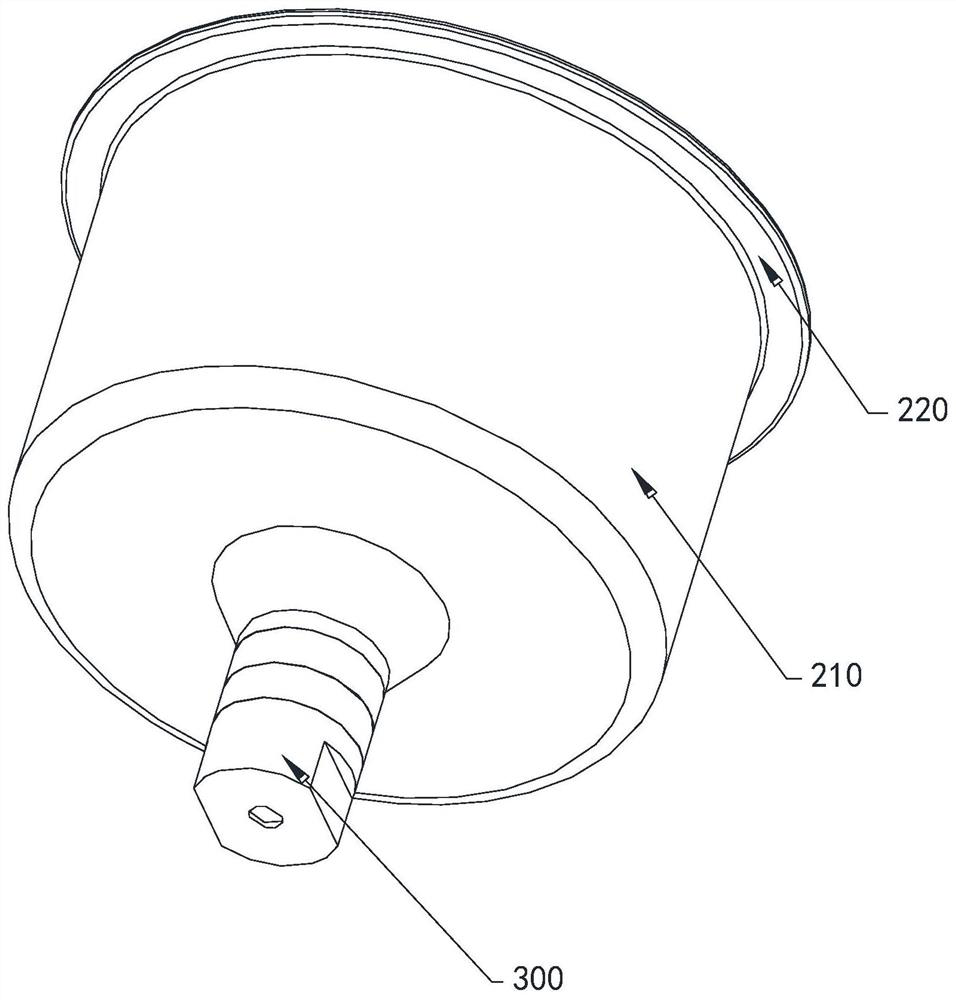

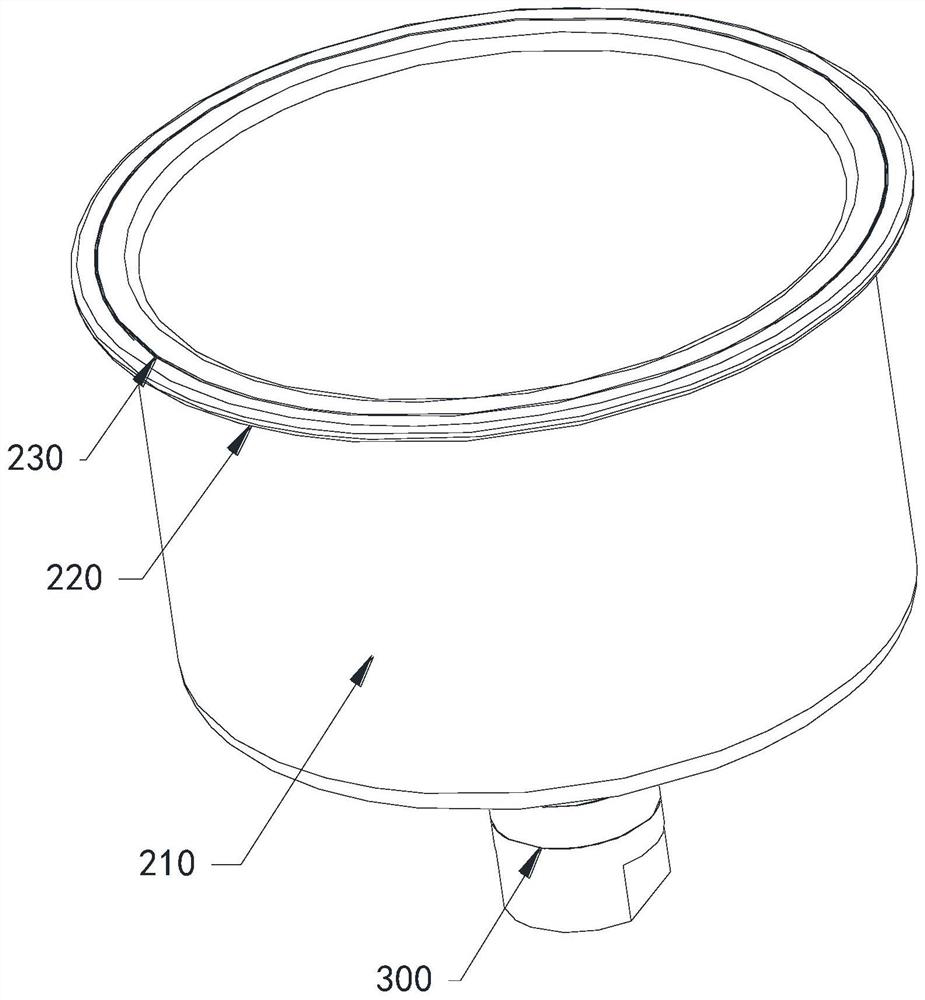

[0025] refer to Figure 1-Figure 5 , a nano-alloy material dispersion equipment, including a frame 100, and also includes a dispersion tank 200 arranged on the machine platform, the bottom and / or side of the dispersion tank 200 are respectively provided with at least one multi-frequency ultrasonic transducer 300, The multi-frequency ultrasonic transducer 300 is electrically connected to the frequency doubling circuit of the ultrasonic generator 400, and the multi-frequency ultrasonic transducer 300 can emit 40KHz-120KHz ultrasonic waves. In electronic circuits, the frequency of the output signal generated is an integer multiple of the frequency of the input signal called frequency multiplication. Assuming that the frequency of the input signal is n, the first frequency multiplier 2n, correspondingly 3n, 4n... etc. ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com