Rotating mechanism

A technology of a rotating mechanism and a driving mechanism, which is applied in the field of aircraft, and can solve the problems that the rotating and folding mechanism is difficult to maintain a stable and reliable unfolded or folded state, the aircraft is damaged, and it is difficult to ensure flight stability. It is easy to process and realize, and guarantees stability. and the effect of safety and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

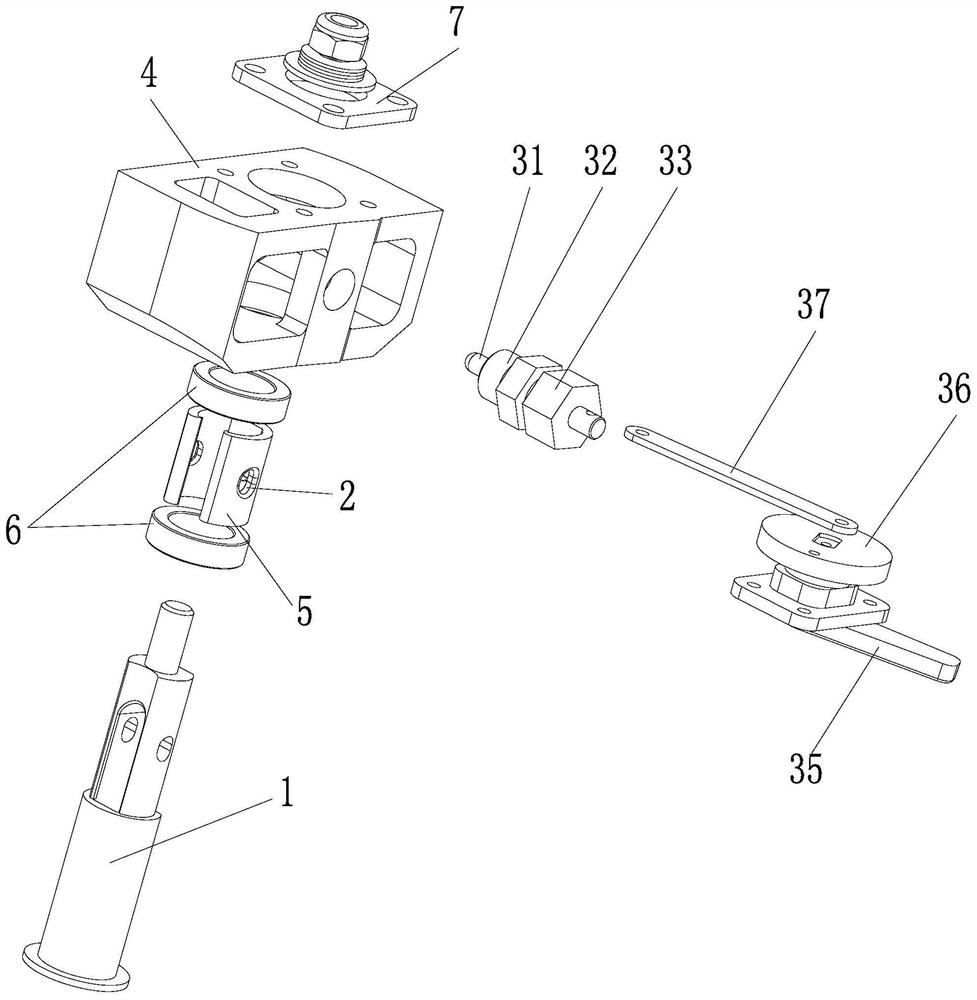

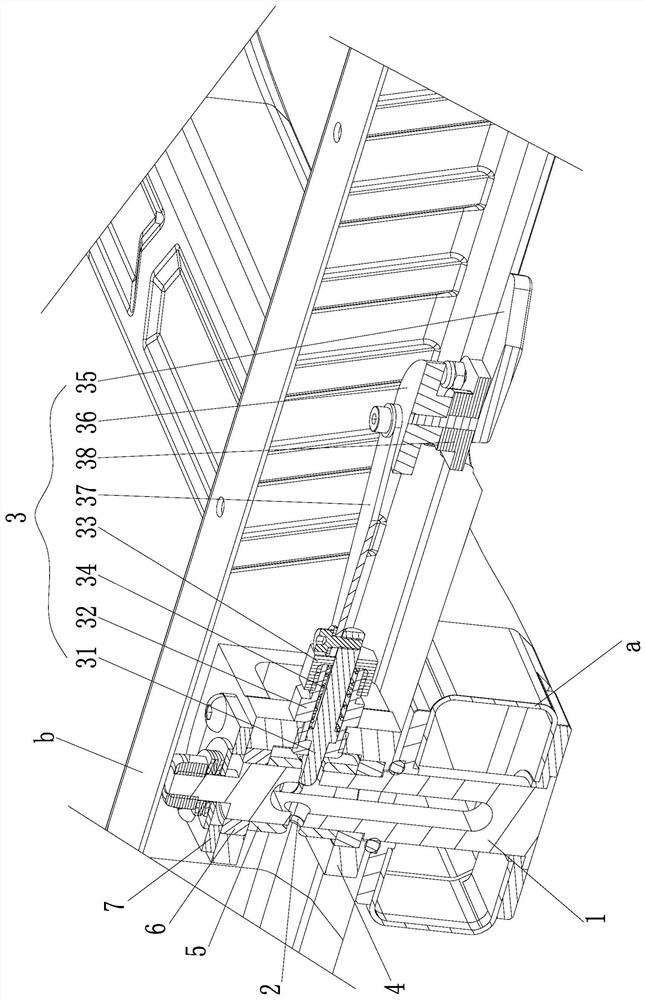

[0025] Such as Figure 1 to Figure 4 As shown, a rotating mechanism mainly includes a rotating shaft 1, a locking part 2 and a locking pin assembly 3, wherein the rotating shaft 1 is fixedly connected to the first pivoting part and is rotatably connected to the second pivoting part, and the locking part 2 is The holes distributed along the circumference of the rotating shaft 1, and the axial direction of the holes are along the radial direction of the rotating shaft 1, the lock pin assembly 3 can move between the locking position and the unlocking position, and the locking pin assembly 3 can be arranged in the waiting position If the pivoting part is on the first part, the locking part 2 is arranged on the second part to be pivoting, or if the lock pin assembly 3 is arranged on the second part to be pivoting, then the locking part 2 is arranged on the first part to be pivoting and / or the shaft 1 , so that relative rotation can be carried out between the first pivoting member a...

Embodiment 2

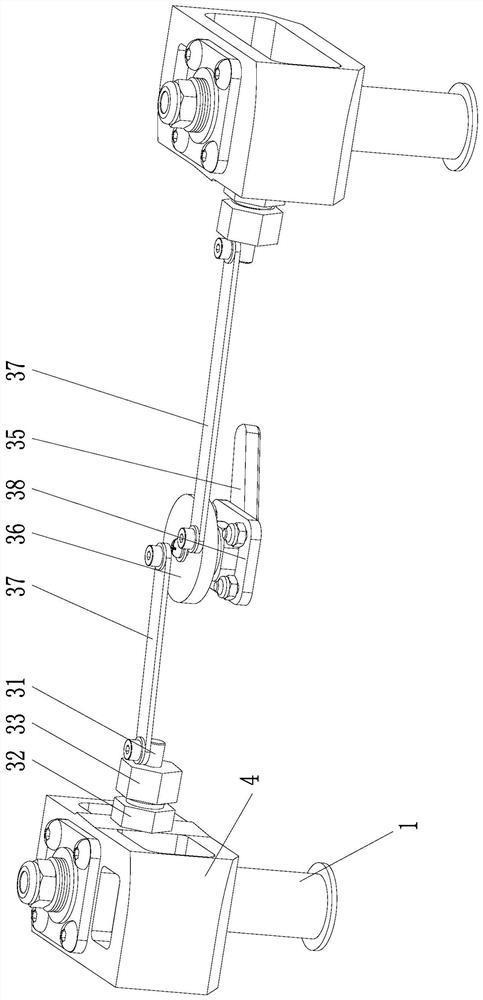

[0036] Such as Figure 5 In the rotating mechanism shown, the rotating shaft 1 is fixedly connected to the main arm b, and the rotating shaft 1 is rotationally connected to the folding arm a. The locking part 2 is a hole arranged on the folding arm a along the circumferential direction of the rotating shaft 1, and the hole The axial direction of is along the axial direction of rotating shaft 1;

[0037] The lock pin assembly 3 mainly includes a lock pin 31 and a lock pin seat 32. The lock pin seat 32 is cylindrical, and the lock pin 31 is inserted on the cylindrical lock pin seat 32 and slides along it to move between the locked position and the unlocked position. Specifically, the axial direction of the locking pin seat 32 is along the axial direction of the rotating shaft 1. When the main arm b and the folding arm a are relatively rotated in place, the locking pin 31 of the locking pin assembly 3 is inserted into the hole so that the main arm b is in the The folding arm a i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com