Automatic cyclic detection device for broken yarn and control method

A technology of roving detection and control methods, applied in textiles and papermaking, etc., can solve the problems of workers' visual fatigue, affecting workers' vision, and high detection intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

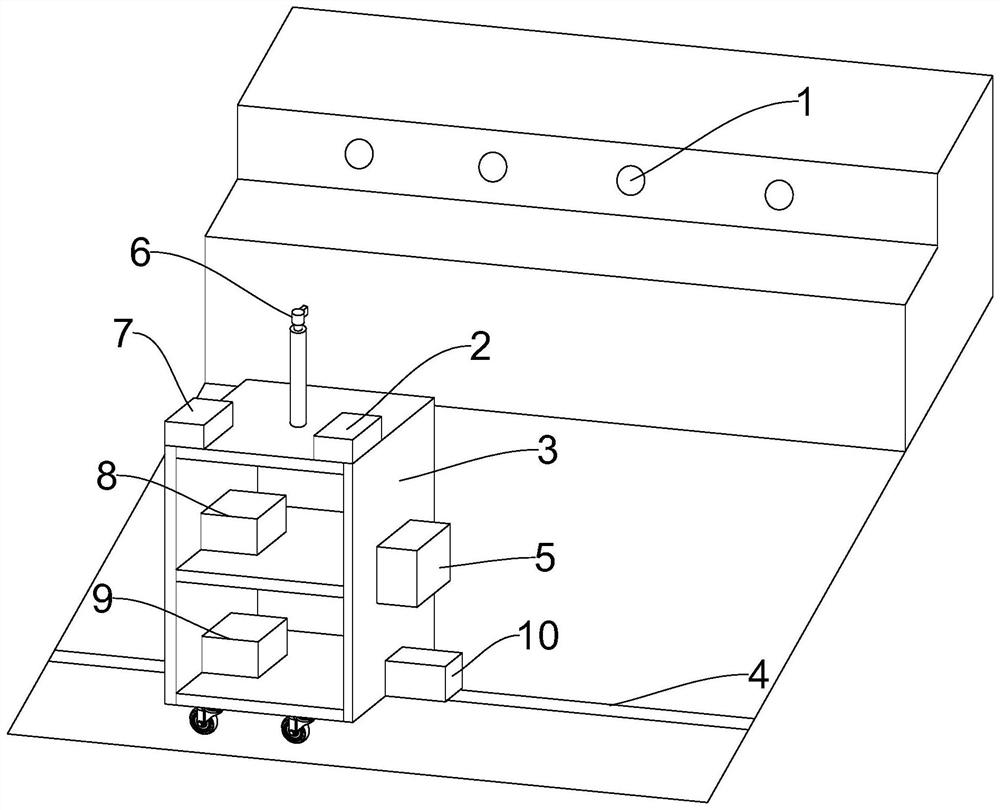

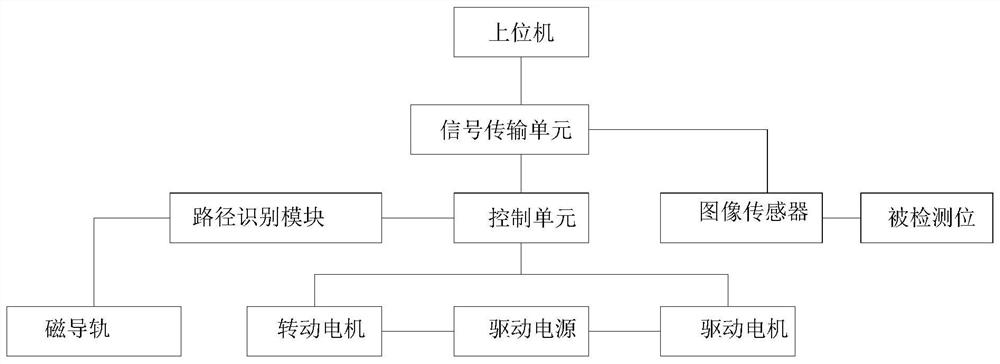

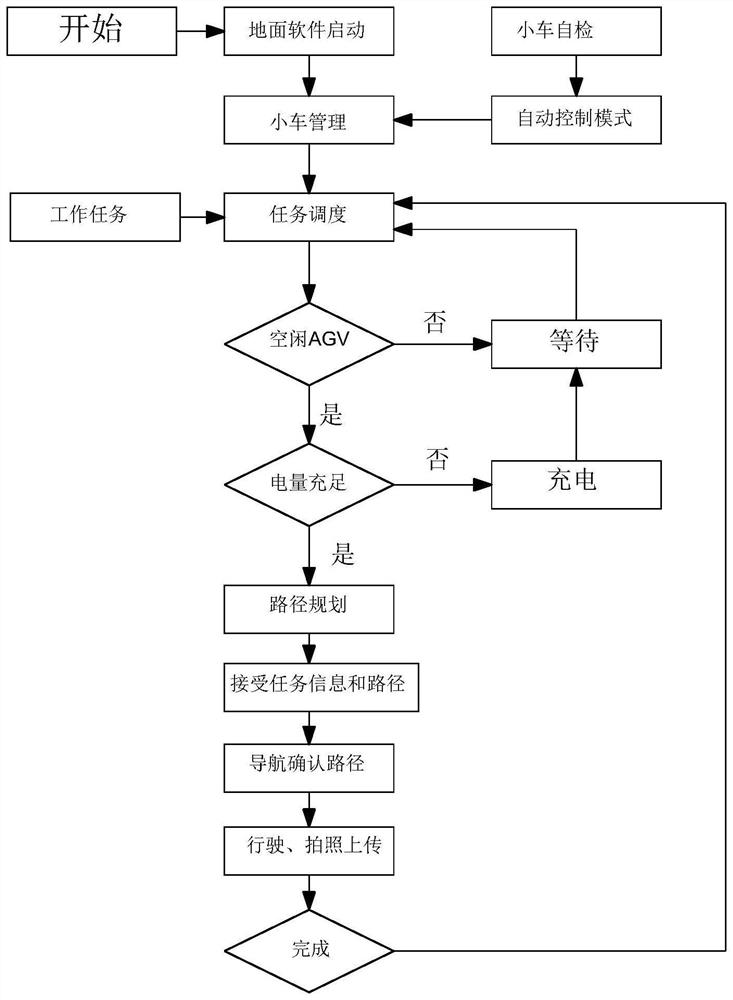

[0042] Please refer to figure 1 , figure 1 Shown is a schematic structural diagram of an embodiment of the present invention. This embodiment provides an automatic yarn breakage roving detection device and a control method, wherein the automatic yarn breakage roving detection device includes a moving component, a sensing component, a signal transmission unit 7, a route Identify the track, control unit 2 and host computer. Wherein, the moving component serves as a carrier of the sensing component and the control unit 2 and can drive the sensing component and the control unit 2 to move. The control unit 2 is used to control the image sensor 6 to perform image acquisition, and at the same time control the moving component to move on the route identification track. The sensing component includes an image sensor 6 , which is arranged on the moving component, and the image sensor 6 can collect image characteristic information of the detected position, and transmit the collected in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com