Construction method for building trench backfilling through vibroflotation slurry-tamping method

A construction method and fertilizer trough technology, applied in construction, excavation, infrastructure engineering, etc., can solve the problems of long construction period and low construction efficiency, and achieve the effects of low cost, saving construction period and high overall work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

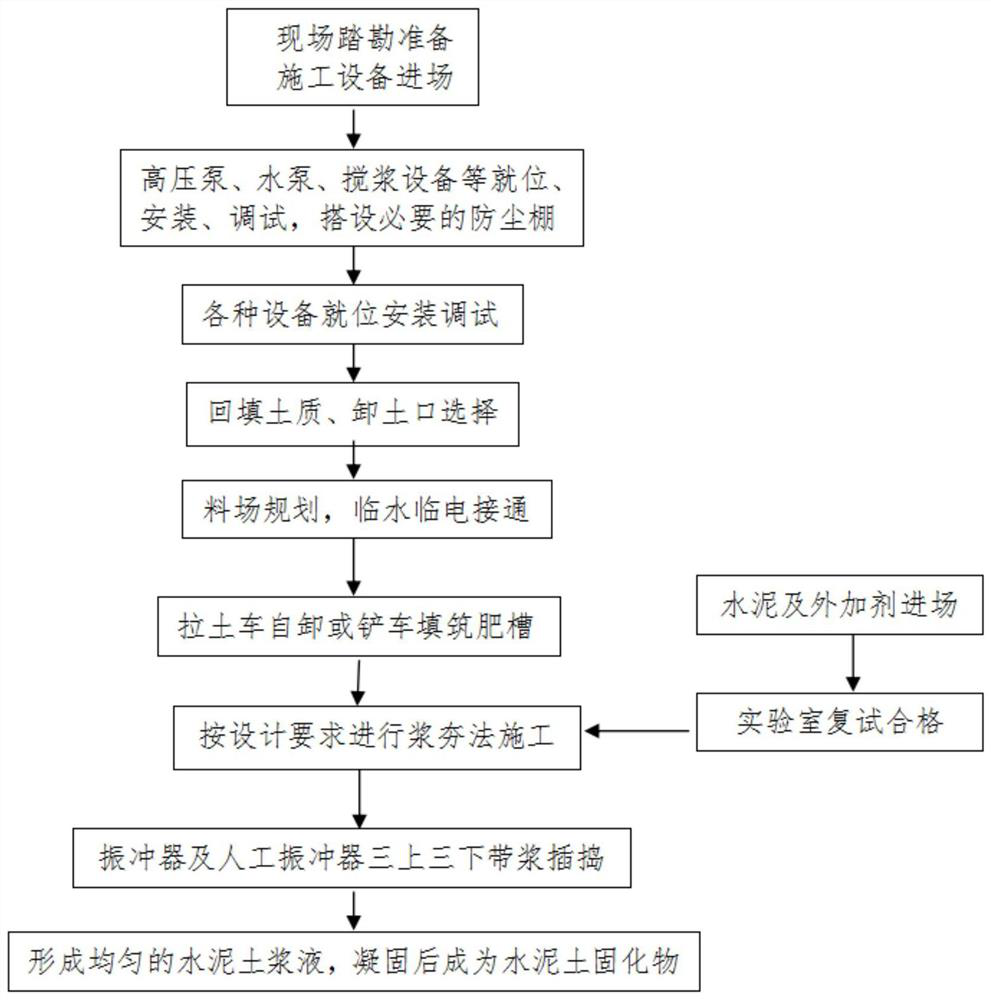

[0038] refer to figure 1 , the invention discloses a construction method for backfilling fertilizer tanks by vibro-ramming method, which can be used for backfilling fertilizer tanks, underground pipe corridors or cavities, etc. The backfilling of fertilizer tanks is taken as an example below, and the backfilling construction method includes the following steps:

[0039] S1. On-site survey preparations, and construction equipment entering the site.

[0040] S2. Put high-pressure pumps, water pumps, mixing equipment, etc. in place, install and debug various equipment, and set up dust-proof sheds if necessary.

[0041] S3. Backfill soil quality and soil unloading port selection.

[0042] S4. Stockyard planning, connecting water and electricity.

[0043] S5. The fertilizer tank is filled by dump truck or forklift, and the fertilizer tank is filled in stages. Eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com