Box type mixer structure meeting national stage VI emission standard

A mixer and box-type technology, applied in machine/engine, muffler, exhaust treatment, etc., can solve the problems of large urea droplets and low NOx conversion efficiency, and achieve small pressure loss, simple structure, and improved uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

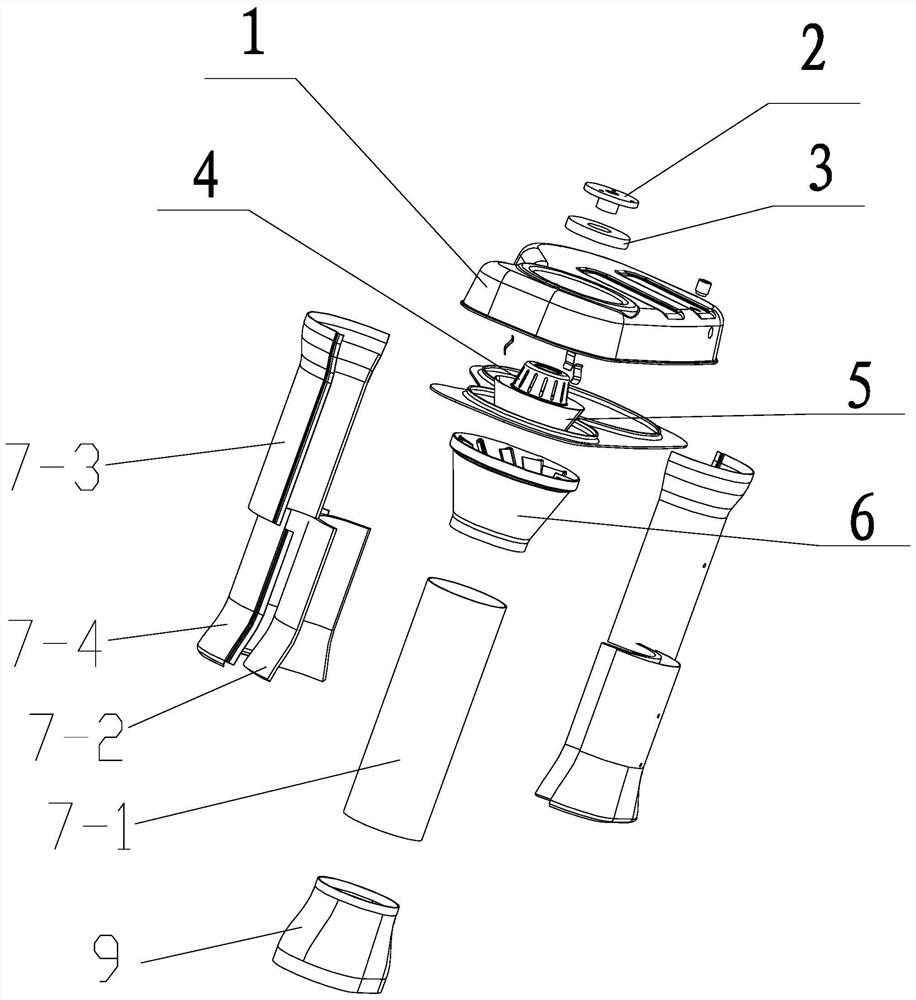

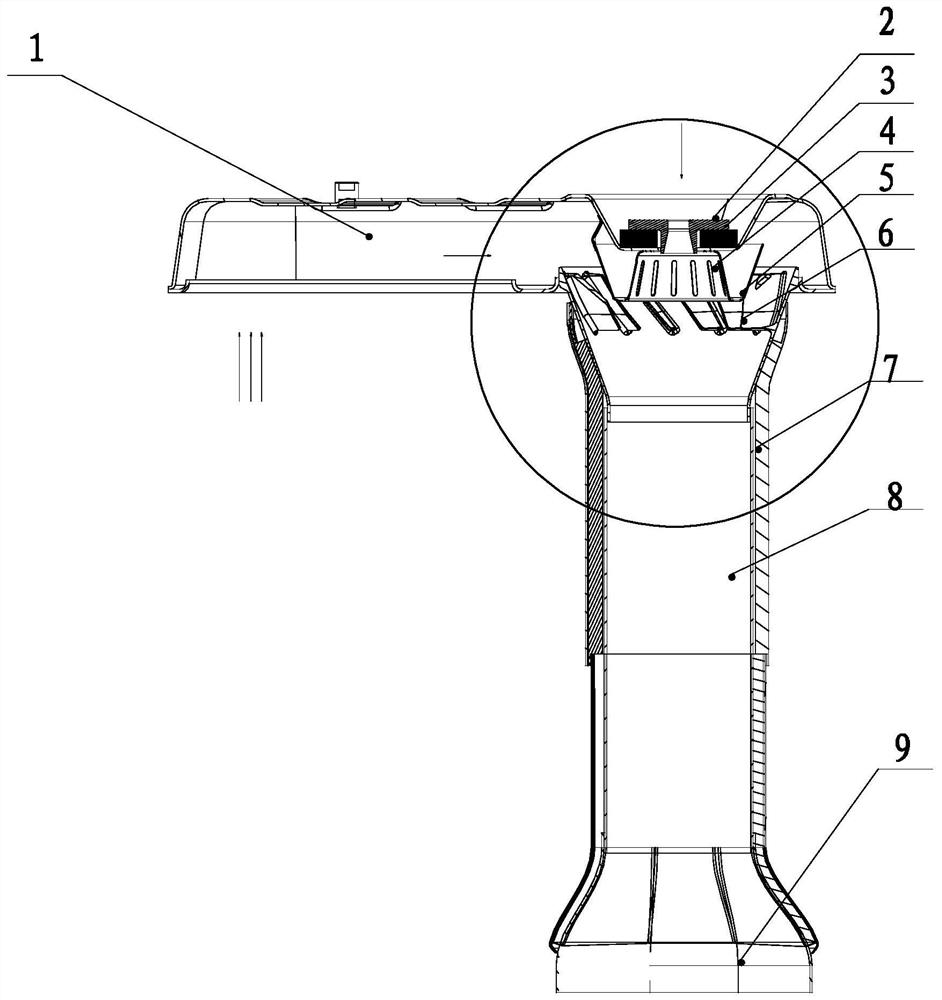

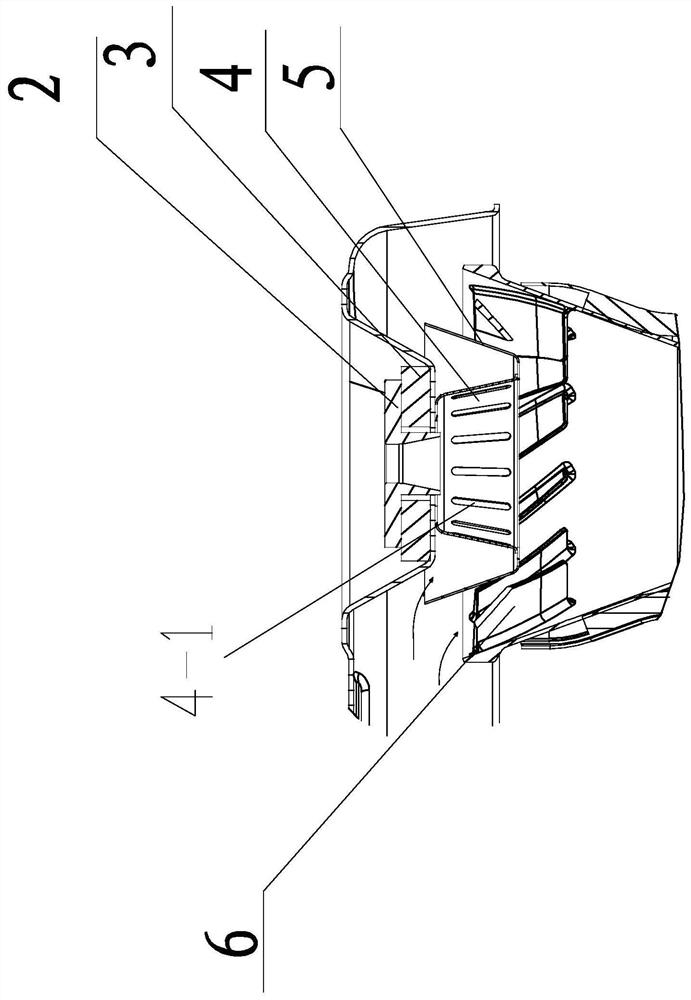

[0022] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] Figure 1-5 Including special-shaped end cover 1, exhaust gas inlet 1-1, urea nozzle groove opening 1-2, urea spray base 2, heat insulation cotton 3, diffusion cover 4, exhaust gas first air intake slot 4-1, installation end cover 5. Mixer 6, double swirl blade 6-1, mixing chamber heat shield 7, heat insulation inner tube 7-1, first heat insulation jacket 7-2, second heat insulation jacket 7-3, third insulation Thermal jacket 7-4, mixing chamber 8, special-shaped end cap joint 9, etc.

[0024] Such as Figure 1-3 As shown, the present invention is a box-type National VI mixer structure, including a special-shaped end cover 1 with an exhaust gas inlet 1-1 at one end, a urea nozzle groove opening 1-2 on the other end, and a lower part connected to the heat shield of the mixing chamber 7. Mixer 6, end cap 5, diffuser cover 4 and urea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com