Transparent substrate provided with antiglare film

A transparent substrate and anti-glare film technology, applied in optics, instruments, optical components, etc., can solve the problem of reduced visibility and achieve high visibility, high anti-glare, and low glare effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

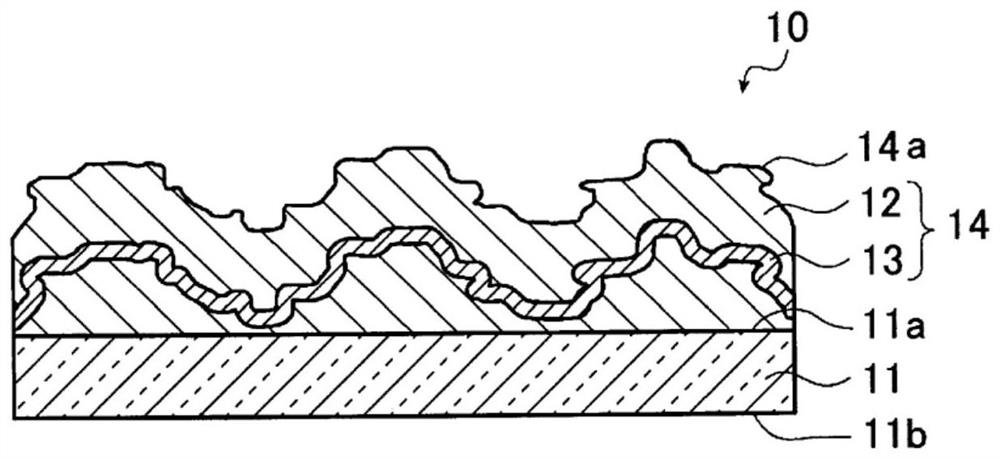

[0058] figure 1 It is a cross-sectional view schematically showing the first embodiment of the transparent substrate with an anti-glare film of the present invention. figure 1 The illustrated transparent substrate 10 with an antiglare film includes a transparent substrate 11 having a first main surface 11a and a second main surface 11b, and an antiglare film 14 formed on the first main surface 11a.

[0059] [Transparent substrate 11]

[0060] As a material of the transparent base 11, glass, resin, etc. are mentioned. Examples of the resin include ethylene terephthalate, polycarbonate, triacetyl cellulose, polymethyl methacrylate, and the like. Among them, it is preferable that the transparent plate is glass from the viewpoint of safety and strength. In addition, glass is also preferably used for vehicle-mounted display members from the viewpoint of high heat resistance and high weather resistance.

[0061] When the transparent base 11 is made of glass, for example, the mec...

no. 2 Embodiment approach

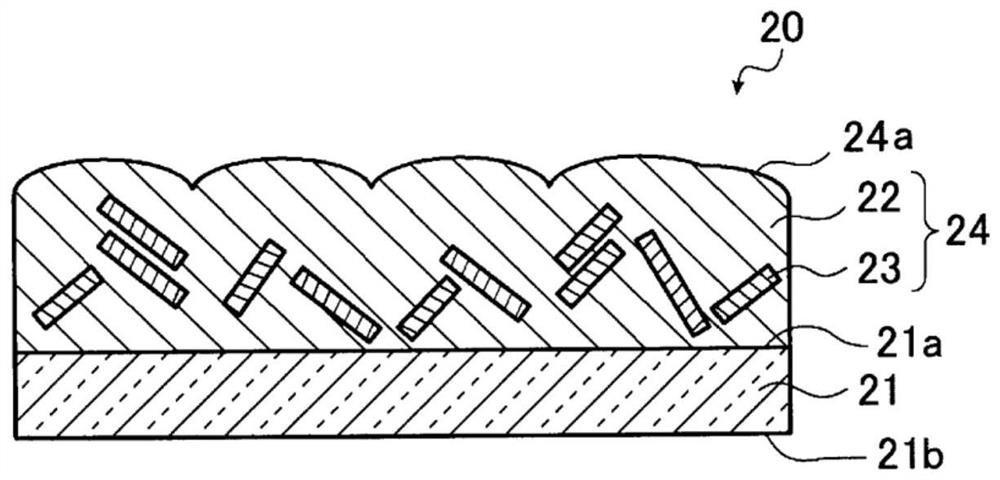

[0117] figure 2 It is a cross-sectional view schematically showing a second embodiment of the transparent substrate with an anti-glare film of the present invention. figure 2 The illustrated transparent substrate 20 with an antiglare film includes a transparent substrate 21 having a first principal surface 21a and a second principal surface 21b, and an antiglare film 24 formed on the first principal surface 21a. The description of the configuration common to the first embodiment is omitted.

[0118] figure 2 In the shown transparent substrate 20 with an antiglare film, the antiglare film 24 consists of a low refractive index layer 22 formed on the first main surface 21a of the transparent substrate 21, and a high refractive index layer formed in the low refractive index layer 22. layer 23.

[0119] figure 2 The high refractive index layer 23 of the illustrated transparent substrate 20 with antiglare film is a discontinuous layer.

[0120] In this specification, a disc...

no. 3 Embodiment approach

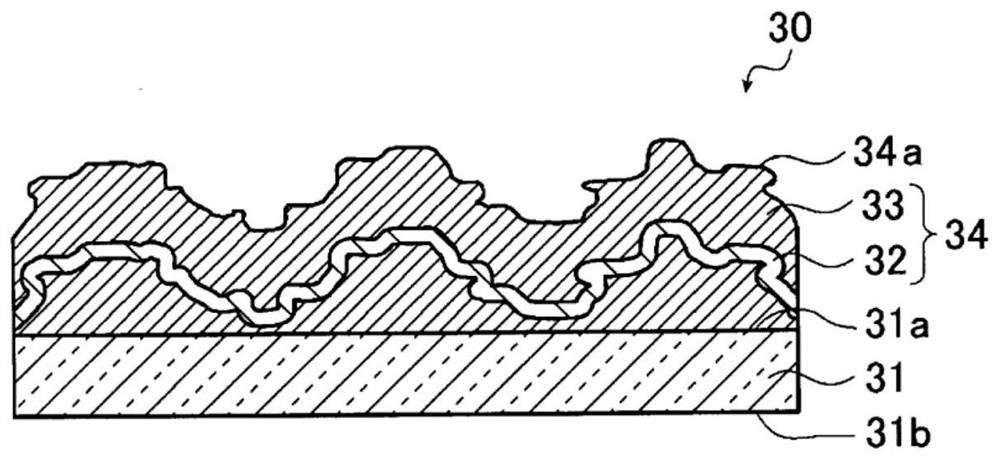

[0151] image 3 It is a cross-sectional view schematically showing a third embodiment of the transparent substrate with an antiglare film of the present invention. image 3 The shown transparent substrate 30 with an antiglare film is formed with a transparent substrate 31 on a first principal surface 31a and a second principal surface 31b, and an antiglare film 34 formed on the first principal surface 31a. The antiglare film 34 It consists of the high-refractive-index layer 33 formed on the 1st main surface 31a of the transparent base 31, and the low-refractive-index layer 32 formed in the high-refractive-index layer 33.

[0152] image 3 The shown low refractive index layer 32 of the transparent substrate 30 with an anti-glare film is a continuous layer.

[0153] That is, it is a configuration in which the low-refractive-index layer 12 and the high-refractive-index layer 13 of the antiglare film 14 of the first embodiment are replaced, and achieves the same effect as that o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com