A track-type railway waste sleeper collection and disposal process, integrated intelligent equipment and its use method

A rail-type, sleeper technology, applied in the direction of using liquid cleaning methods, chemical instruments and methods, cleaning methods and utensils, etc., can solve problems such as increased damage, backward design theory and manufacturing process, and idleness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Please refer to Image 6 As shown, the embodiment of the present invention is a collection and disposal process of railway waste rail sleepers, which includes the following steps: the following steps are all controlled by the control center, specifically,

[0057] S1: Machine grabbing: the control center controls the intelligent device to use machines to grab waste sleepers to realize intelligent collection;

[0058] S2: Pre-spraying: for the sleepers collected in step S1, the control center controls the dust removal device to perform pre-spraying and dust removal treatment;

[0059] S3: primary crushing: the control center controls the crushing device 1 to cut the sleeper;

[0060] S4: Secondary crushing: the control center controls the crushing device 2 to completely crush the sleepers after the primary crushing;

[0061] S5: Magnetic separation: the control center controls the magnetic separation device to recover metal by magnetic suction;

[0062] S6: Aggregate ...

Embodiment 2

[0063] Example 2: Integrated intelligent equipment for the collection and disposal of railroad waste sleepers

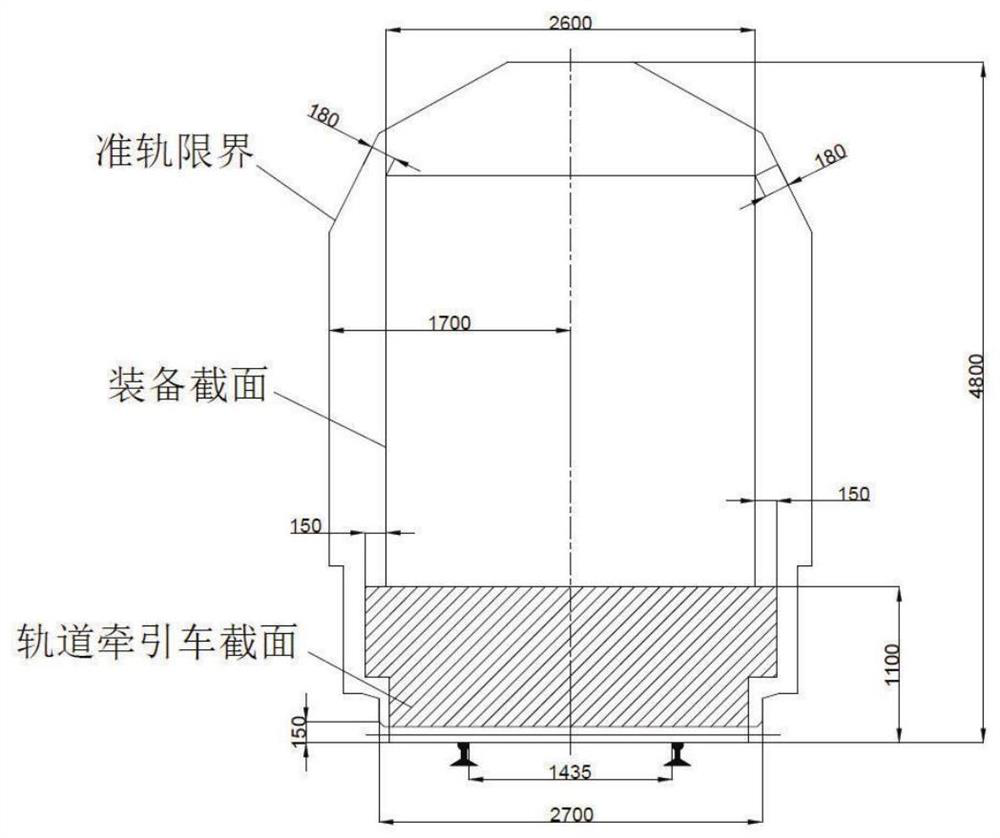

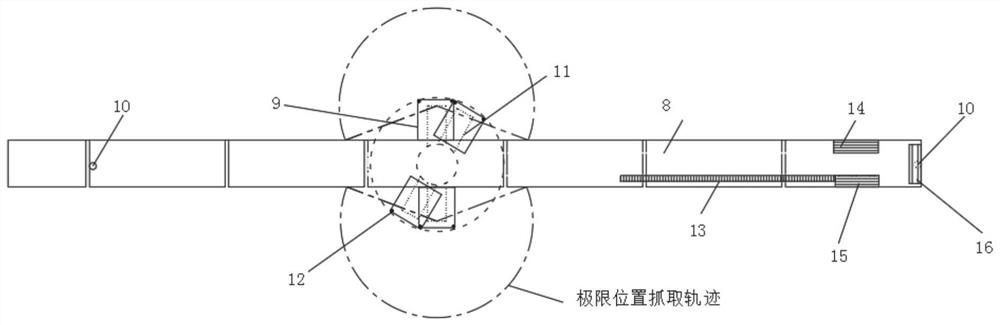

[0064] In the embodiment of the present invention, please refer to figure 1 As shown, an integrated intelligent equipment for the collection and disposal of railroad waste sleepers includes a rail tractor 1, a control center 2, a dust removal device 3, an intelligent grabbing device 4, a crushing device 5, and Metal separation device 6, concrete separation device 7;

[0065] The intelligent grabbing device 4 is used to grab waste sleepers to the crushing device 5;

[0066] The discharge port of the crushing device 5 is connected to the feed port of the metal separation device 6, and is used to transport the crushed material to the metal separation device 6 for metal separation;

[0067] The discharge port of the metal separation device 6 is connected to the feed port of the concrete separation device 7, and is used for transporting the metal-separated material to t...

Embodiment 3

[0082] Embodiment 3: The use method of the integrated intelligent equipment for the collection and disposal of railroad waste sleepers

[0083] In the embodiment of the present invention, the method of using the integrated intelligent equipment for collecting and disposing of railroad waste sleepers as described in Embodiment 2 is as follows:

[0084] Include the following steps:

[0085] S1: Install the above-mentioned integrated intelligent equipment for the collection and disposal of railroad waste sleepers above the track;

[0086] S2: The head of the rail tractor provides traction so that the integrated intelligent equipment runs along the track above the track;

[0087] S3: Mechanical grabbing of sleepers: During operation, use the mechanical arm of the intelligent grabbing device to complete the identification and grabbing of waste sleepers, place them on the designated position of the conveyor belt with high precision, pass through the conveyor belt into the spray roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com