A combined movable railway sleeper collection and disposal process and an integrated collection and disposal machine

A combined, all-in-one technology, applied in the direction of roads, tracks, solid separation, etc., can solve the problems of waste of resources, occupying land resources, difficult to deal with additional environmental burdens, etc., and achieve the effect of complete recycling and disposal, compact structure and novel design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

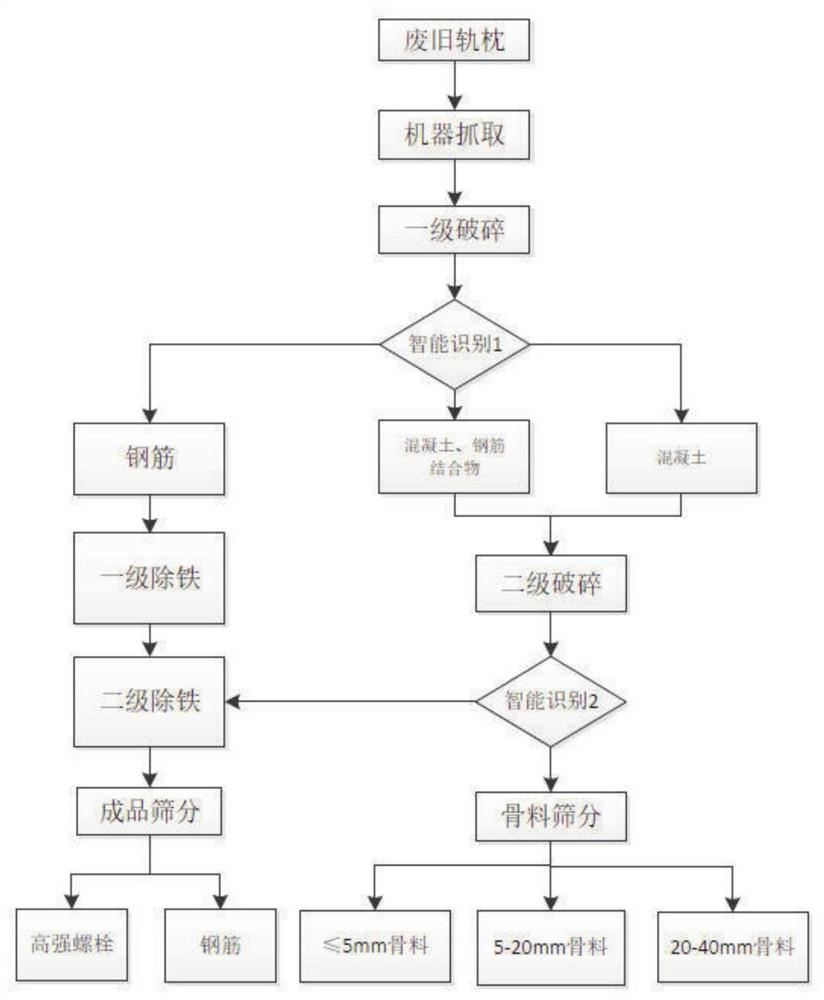

[0057] Example 1: Combined movable railway sleeper collection and disposal process

[0058] In the embodiment of the present invention, please refer to figure 2 As shown, a combined movable railway sleeper collection and disposal process includes the following steps:

[0059] S1: Mechanical grabbing: Mechanical grabbing of sleepers to the mechanical feeding system, through which the mechanical feeding system transports them into the primary crushing system;

[0060] S2: primary crushing: performing primary crushing on the sleepers transmitted in step S1;

[0061] S3: Intelligent identification: the sleeper processed in step S2 enters the conveying device, and the steel bars in the identified sleeper are transported to the iron removal process by identifying ferromagnetic substances, and the other part of the concrete aggregate that does not identify ferromagnetic substances It is lifted to the secondary crushing process through the conveying device;

[0062] S4: Iron remov...

Embodiment 2

[0076] Example 2: Combined mobile integrated machine for collecting and disposing of waste railway sleepers

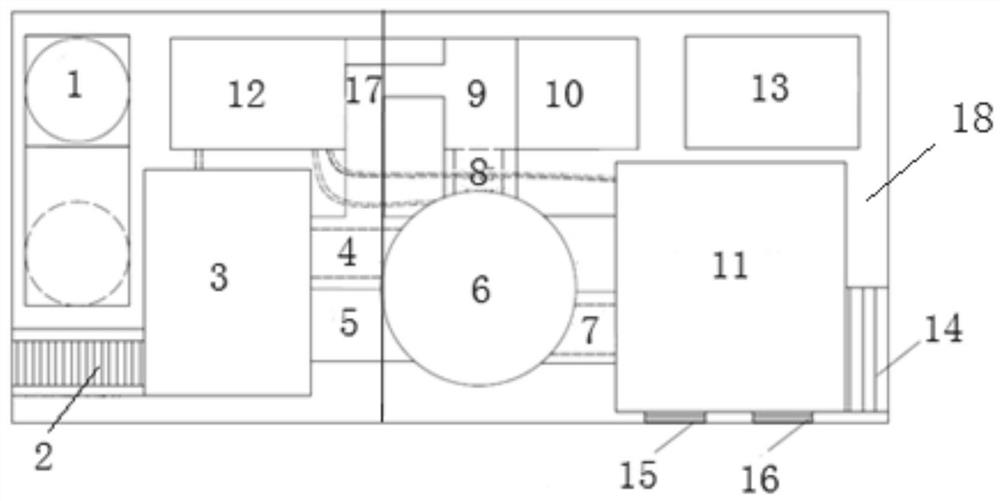

[0077] Please refer to figure 1 As shown, a combined movable railway sleeper collection and disposal integrated machine includes a car body 18

[0078] The car body 18 includes sequentially setting a mechanical reclaiming system 1, a mechanical feeding system 2, a primary crushing system 3, a first photoelectric identification 4, a first feeding device 5, and a secondary crushing system according to the process described in embodiment 1. System 6, second feeding device 7, second photoelectric identification 8, secondary iron removal system 9, second screening system 10, first screening system 11, conveying device 12, environmental protection system 12 and control system 13;

[0079] The conveying device comprises a first conveying device 14, a second conveying device 15, and a third conveying device 16;

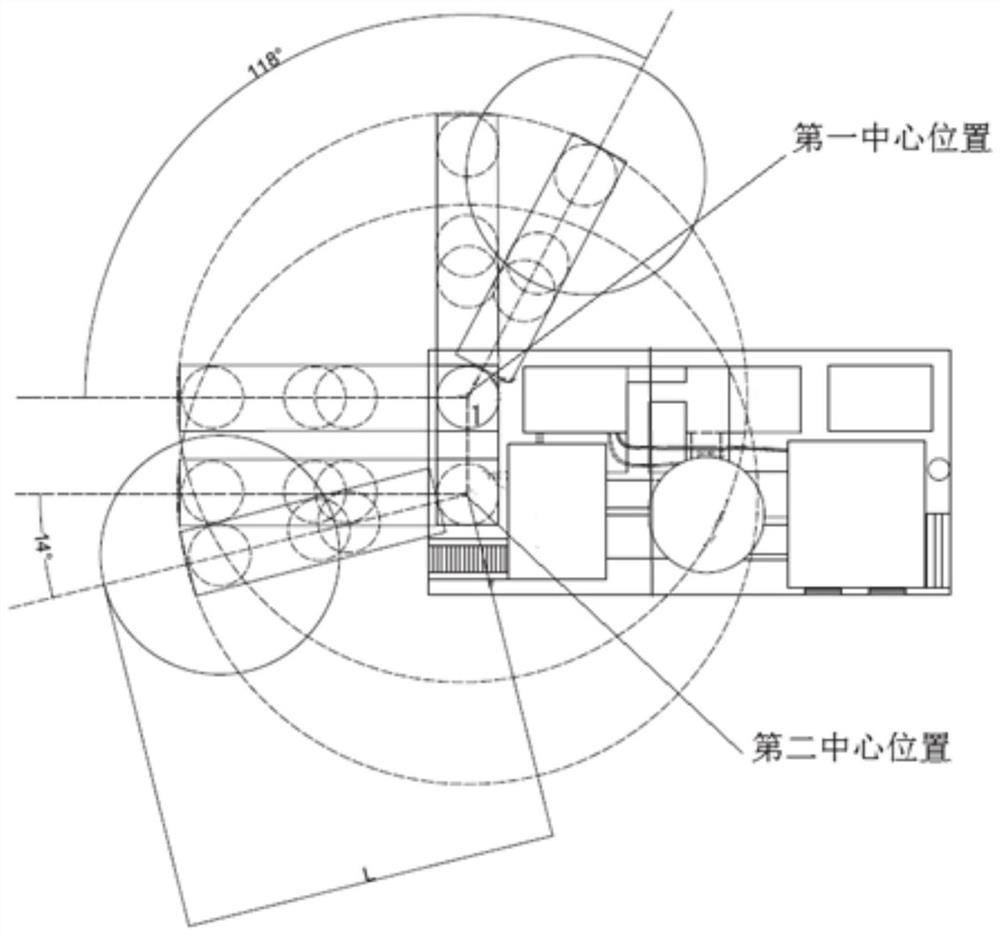

[0080] The mechanical reclaiming system 1 is provided with a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com